S1

Direction of rotation

Pos. 0

Actuator has stopped (undefined position)

Pos. 2

Cooling

Pos. 3

Heating

Modulating actuators

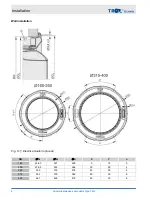

Fig. 16: Variable control

①

Setpoint adjuster: Y = voltage signal

2-10 V DC

②

Modulating actuator

(0) 2 V - Travel stop – cooling

10 V

- Travel stop – heating

Commissioning

Initial commissioning

Before you start commissioning:

Check that the jet nozzles are correctly seated.

Remove protective film, if any.

Ensure that all jet nozzles are clean and free

from residues and foreign matter.

Check that electrical connections (if any) have

been correctly made.

Ensure that the devices have been correctly

fixed and connected to the ducting.

For jet nozzles with electric actuator: Check

that the position of each discharge nozzle

matches the operating mode,

Ä

Chapter

7.3 ‘Operating modes ’ on page 14

Note:

If the position of the discharge nozzle is not

as it should be, you can change the direction of

rotation on the actuator by swapping the terminal

connections.

For commissioning see also VDI 6022, part 1 – 'Hy-

giene requirements for ventilation and air-condi-

tioning systems and units'.

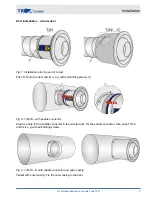

Thermal actuator T1

The smallest and largest swivel angles are reached

with supply air temperatures of ≤ 18 °C and

≥ 30 °C.

Be sure to position the jet nozzle correctly for instal-

lation,

Ä

5.1 ‘Installation orientation’ on page 6

. An

incorrect position may impair its function.

A 'standard' jet nozzle cannot be retrofitted with a

thermal actuator unit at a later stage since a

thermal actuator requires a casing that is 60 mm

longer.

Jet nozzles with thermal actuator may be factory

fitted with a swirl unit (option) but it is not possible

to retrofit a swirl unit at a later stage.

Removing the factory mounted swirl unit may impair

the function of the jet nozzle.

Commissioning

Air terminal devices Jet nozzle Type TJN

13