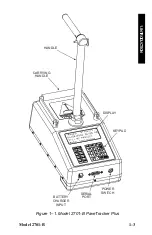

Model 2701-B

1–7

1. INTR

OD

UCTI

O

N

UNPACKING AND INSPECTION

NOTE

To ensure the safe return of the PaveTracker Plus to

Troxler for repair or maintenance, please keep the

original shipping boxes and all packing materials.

Upon receipt of the gauge from the factory:

1.

Perform a complete inspection and inventory. If the shipping

case and/or any other part or accessory appears damaged, notify

the carrier and your Troxler representative

immediately

.

2.

Check the shipping case for the following:

♦

Model 2701-B PaveTracker Plus

♦

Carrying Case (PN 113034)

♦

Handle (PN 113210)

♦

AC Charger (PN 110403)

♦

DC Adapter (PN 104156)

♦

2701-B Cover Kit (PN 113107), containing replacement

bottom covers and cleaning wipes

♦

Manual of Operation and Instruction (PN 113045)

3.

Lift the gauge from the carrying case and inspect the outside

surface for damage.

Summary of Contents for 2701 -B

Page 8: ...viii NOTES ...

Page 12: ...xii NOTES ...

Page 20: ...1 8 NOTES ...

Page 84: ...Appendix B 6 NOTES ...

Page 94: ...Index 6 NOTES ...