5-2

Handling Project Data

The Model 2701-B can store approximately 1000 readings.

The

Project

and

Store

functions allow handling of

measurement data. Measurement results are stored in files

(memory locations) called

projects

, which are named by the

operator. The

Project

function allows the operator to create a

new project, view project data, select a project (make an

existing project active so that additional data may be added

to it), output the data stored in the project, or erase projects.

The

Store

function allows the operator to store measurement

results and other test-identifying information in a selected

project. Refer to page 5-10 for information on the

Store

function.

To access the

Project

function, press the

〈

PROJ

〉

key. The

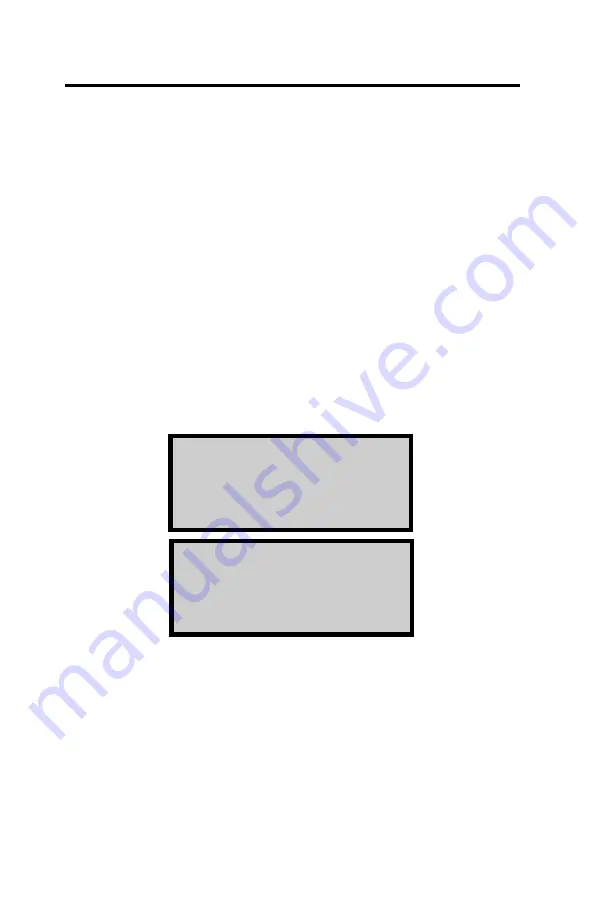

gauge displays the

Project

menu:

Use the arrow keys to scroll through the menu options. Use

the numeric keys to select a menu option. Press

〈

ESC

〉

to

return to the

Ready

screen.

- Pr oj ect -

4. Er ase

5. Out put

- Pr oj ect -

1. Sel ect

2. Vi ew

3. Cr eat e

Summary of Contents for 2701-B

Page 9: ......

Page 20: ...1 8 NOTES...

Page 74: ......

Page 86: ...Appendix A 12 NOTES...

Page 92: ...Appendix B 6 NOTES...