Troxler NTO

1–5

1. INTR

OD

UCTI

O

N

FEATURES OF THE TROXLER NTO

The oven incorporates a number of features that provide

unparalleled efficiency, safety, usability, and flexibility.

The oven heats the HMA sample using an

infrared (IR) element

.

The use of IR radiation serves two purposes: it limits the heating of

the aggregate material in the HMA sample while producing a very

efficient and clean burn process.

The oven can be powered from a 120 V ac, 50/60 Hz, 12 A source

(Model 4730) or from a 208–240 V ac, 50/60 Hz, 12/13 A source

(Model 4731). The oven is therefore convenient for use in

construction trailers, where power sources may be limited.

The

oven door lock

helps ensure operator safety. The oven monitors

the state of the door, and will not apply electrical power to the IR

element if the door is open. The oven door is locked automatically

at the start of a burn cycle. The door remains locked until five

minutes have elapsed since the chamber temperature has peaked or

since the

〈

ABORT

〉

key was pressed.

The

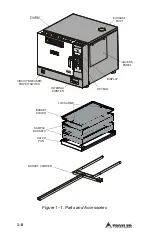

sample basket assembly

is designed to provide operator safety

while handling HMA samples, and to ensure an even burn of the

asphalt binder. A

basket carrier

is provided for lifting the baskets in

and out of the oven. A

sample safety cage

shields the hot sample

basket assembly while the asphalt sample cools.

The

integrated scale

continuously monitors the sample mass loss

during a burn cycle.

The oven features an

Auto-Tare

function that automatically tares

(zeroes) the integrated scale when no mass is present. The oven

software also enables the operator to tare the scale manually, to

calibrate the scale, and to verify the scale calibration.

The oven

keypad

and

internal logic

provide control, data storage,

and output flexibility. The keypad enables the operator to set up and

operate the oven, to store sample data, to calibrate and verify the

integrated scale, and to enter correction factors.

The oven includes an

Auto-Timer

function that can preheat the oven

automatically based upon start and stop dates and times entered by

the operator.

Summary of Contents for NTO 4730

Page 10: ...x LIST OF TABLES Table Title Page 4 1 Oven Keys 4 3 5 1 Recommended Minimum Burn Times 5 6...

Page 30: ...2 10 NOTES...

Page 90: ...5 36 NOTES...

Page 110: ...6 20 NOTES...

Page 136: ...Appendix A 16 NOTES...

Page 148: ...Appendix C 6 NOTES...

Page 156: ...Index 8 NOTES...