2–6

SAFETY WARNINGS

The Troxler NTO Asphalt Content Ignition Oven is a safe, durable

unit. Troxler cannot anticipate every example of improper or

unauthorized use of this oven that may lead to malfunction or

accident. If a particular use is

not specifically mentioned

in this

manual as authorized, then assume that the use is unauthorized and

improper.

Always follow the safety warnings in this manual and the safety

procedures of your laboratory/company. Refer to the MSDSs

provided with each oven for further safety information. Troxler

recommends the following safety precautions.

READ ALL INSTRUCTIONS CAREFULLY

♦

The installation of the oven must comply with local building

code rulings.

♦

Troxler recommends the installation of a carbon monoxide

detector.

♦

Keep the area around the oven clear and free from all

combustible materials, gasoline, and other flammable vapors

and liquids. Failure to do so could cause fire or explosion.

♦

Place the oven on a level, sturdy, fireproof surface.

♦

The ambient temperature should be between 10 and 50

°

C (50

and 122

°

F), and the relative humidity should be less than 92%.

♦

Allow at least 15 cm (6 in.) between the oven and other vertical

structures.

♦

During normal operations, the chamber door cannot be opened

during a burn cycle. However, if the door lock should fail or be

defeated by the operator, it may be possible to open the door

while combustion is occurring inside the oven. If this should

happen, flames may exit from the top of the door. Therefore,

there must be at least 91 cm (3 ft) of clearance above the oven.

♦

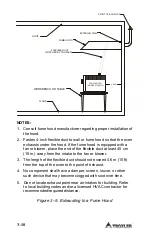

Locate the oven

no more than

1.2 m (4 ft) from the required

electrical power source (see Appendix C). Ensure that the

distance does not place stress on the power cord. The power

source must be wired by a qualified electrician.

Summary of Contents for NTO 4730

Page 10: ...x LIST OF TABLES Table Title Page 4 1 Oven Keys 4 3 5 1 Recommended Minimum Burn Times 5 6...

Page 30: ...2 10 NOTES...

Page 90: ...5 36 NOTES...

Page 110: ...6 20 NOTES...

Page 136: ...Appendix A 16 NOTES...

Page 148: ...Appendix C 6 NOTES...

Page 156: ...Index 8 NOTES...