6–4

4.

Prepare a correction sample that closely represents the

production mixture per ASTM D 6307, or local and state

requirements.

5.

Divide the HMA sample into a minimum of three correction

samples.

6.

Preheat the sample to 105

±

5

°

C (221

±

9

°

F).

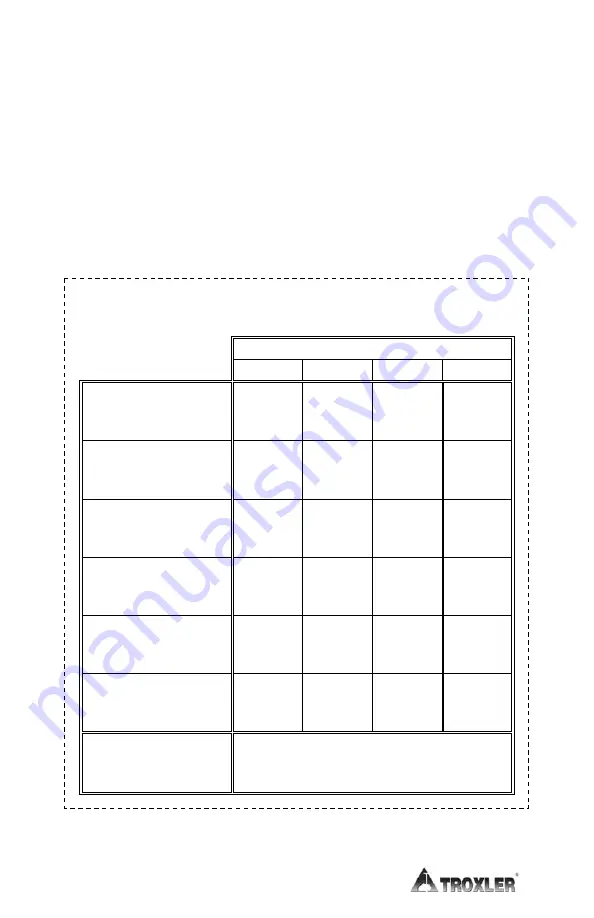

Figure 6–1. Sample Aggregate Correction Factor Form

Date ___________ Project ________________ %AC

T

________

Sample

Number

1 2 3 4

Sample Basket, Catch

Pan, and Basket Cover

Mass (W

P

)

Sample, Sample Basket,

Catch Pan, and Basket

Cover Mass (W

T

)

Sample Weight

(W

S

=W

T

–W

P

)

True Asphalt Content

(%AC

T

)

Asphalt Content of

Sample Measured by

Oven (%AC

0

)

Correction Factor

(ACF = %AC

0

– %AC

T

)

Average Aggregate

Correction Factor

(ACF

AVG

)

Summary of Contents for NTO 4730

Page 10: ...x LIST OF TABLES Table Title Page 4 1 Oven Keys 4 3 5 1 Recommended Minimum Burn Times 5 6...

Page 30: ...2 10 NOTES...

Page 90: ...5 36 NOTES...

Page 110: ...6 20 NOTES...

Page 136: ...Appendix A 16 NOTES...

Page 148: ...Appendix C 6 NOTES...

Page 156: ...Index 8 NOTES...