ASSEMBLY CHECKLIST

Crate Inspection

❏

Inspect crate for evidence of

product damage. If any suspect

damage exists, contact the carrier

(trucking company) immediately.

Tools

❏

Crowbar (for unpacking)

.

❏

Tire pressure gauge.

Unpacking

❏

Using crowbar, remove crating

from around unit. Remove ties

securing wheels to crate. Remove

material securing front wheel

spindles to crate.

❏

With a 9/16" wrench, remove

hardware securing back of unit to

crate.

❏

Unpack complete unit. Inspect all

parts. Inspect contents of hardware

pack against following list.

Product Content

❏

Tractor.

❏

Hardware bag (includes):

All Units:

...........Hitch pins (for attachments)...2

...........Oil drain hose .........................1

...........Ignition key (spare) ................1

ALL MODELS:

❏

Grease wheel bearings with multi-

purpose grease at grease fittings.

Tire Pressure

❏

Use air pressure gauge to check

tire pressure. Adjust as necessary.

FRONT TIRES: 12-14 PSI (82-96

kPa)

REAR TIRES: 8-10 PSI (55-69

kPa)

Note: Operators with trouser inseam

lengths shorter than 38" should use

front hole in seat bracket; operators

with inseam lengths 38" and over

should use rear hole in seat bracket.

❏

Plug seat interlock lead (Fig. 6) into

interlock switch on bottom of seat.

Roll Unit Off Crate

❏

Check crate for, and remove, any

nails/sharp objects which could

puncture tires.

❏

Engage parking brake.

❏

Place transmission into neutral as

follows:

MODEL 130F063:

This unit can be pushed by hand any

time the engine is not running and the

parking brake is not set.

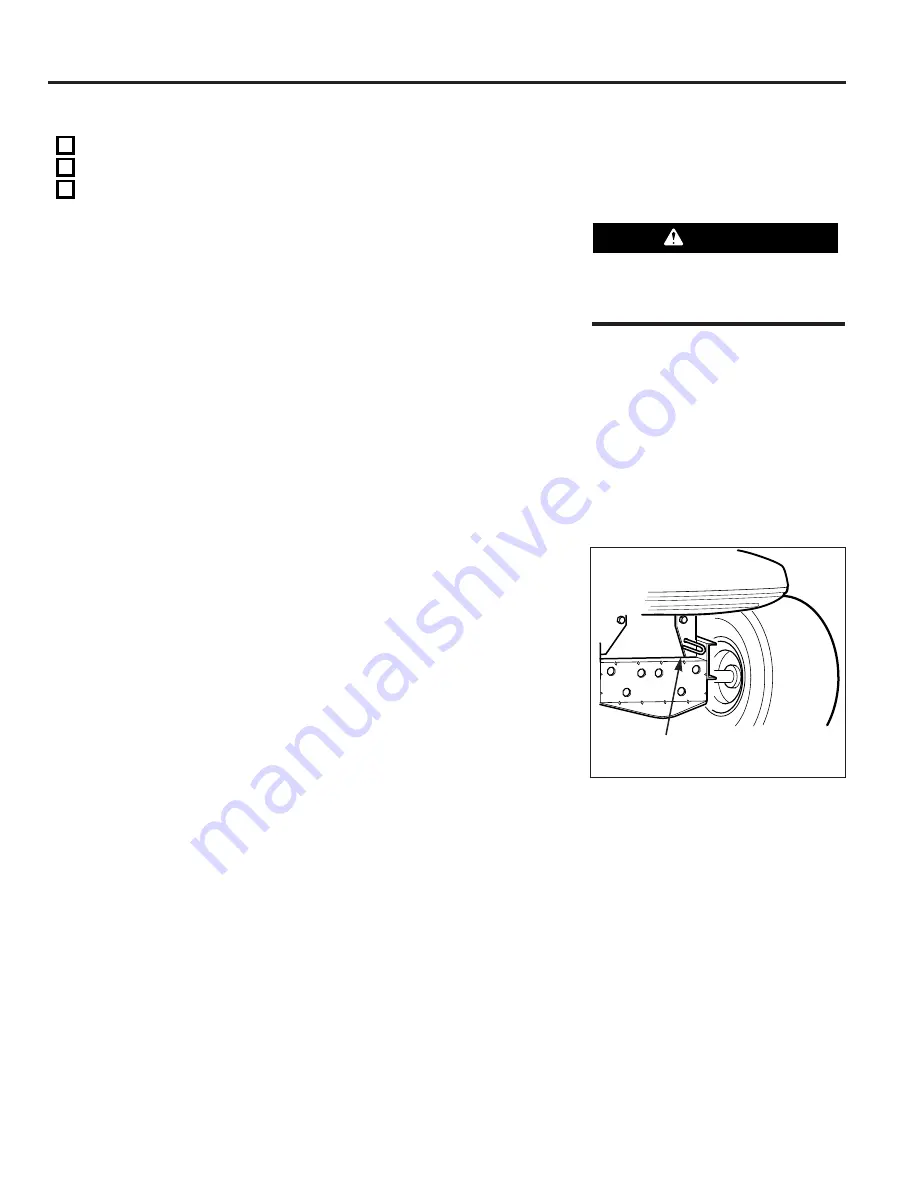

MODEL 145F063:

Pull hydrostatic freewheeling actuator

(Z, Fig. 5) out and rotate to place in

the locked position.

Note: After pushing unit, return the

freewheeling actuator back to the

normal position. Transmission will not

drive unit when freewheeling actuator

is engaged.

❏

Roll unit off crate.

Engine

Note: Refer to the engine manual

provided with your unit for more

specific engine oil information.

DO NOT OVERFILL ENGINE WITH OIL.

ENGINE IS SHIPPED FROM THE FACTORY

WITH OIL.

❏

Check the engine for proper oil

level.

If necessary, top-off engine oil level

with the proper type and quantity of

engine oil (determine type and

quantity of oil by following recom-

mendations indicated in the engine

manual).

CAUTION

✓

2

Assembly

Fig. 5

Z

Model 145F063 only