17

•

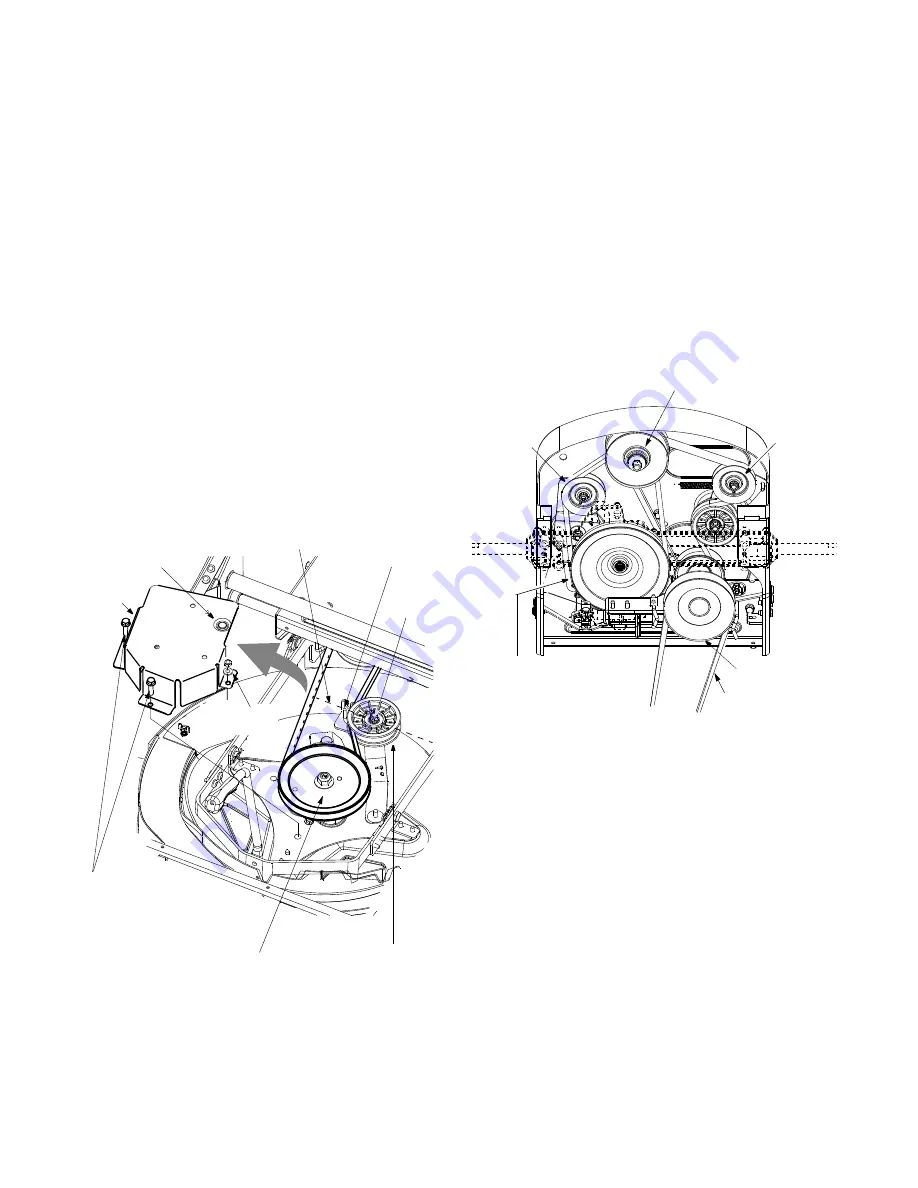

Remove belt from around deck pulley, idler pulley,

and the engine pulley.

•

Place the new belt around the deck pulley and the

engine pulley making sure that the belt is routed

inside the belt keepers. There are two belt keepers

under the grasscatcher, one on the idler and the

other under the deck belt cover. See Figure 15 .

•

Reinstall the deck belt cover and secure with the

two self-tapping screws and the lock washer and

hex nut. Make certain the belt keeper “B” is outside

of the belt.

NOTE: Belt keeper “A” must be mounted on the inside

of the belt. There should be a 1/8” clearance between

the belt and the belt keeper.

•

Make sure to align the belt keeper in line with the

frame. See Figure 15 .

•

Again working from under the rear of the mower,

reinstall the rear deck belt guard.

•

Replace the grasscatcher and pivot the seat frame

back.

NOTE: An imaginary line between the belt keeper and

idler pulley should be parallel to frame.

Lower Variable Speed Belt

•

Remove the rear deck belt guard following first five

steps for deck belt removal. Remove belt from the

engine pulley.

•

Push the spring loaded idler, located on the left side

of the transmission, to the right. Remove belt from

around the idler and then the transmission pulley.

See Figure 15 .

•

Using a 9/16” socket, remove bolt, spacer and the

flat washer from the variable speed pulley. See

Figure 16 .

•

Drop the pulley down and remove the belt.

•

Replace new belt and reassemble following above

instructions in reverse order.

•

Make sure that the belt is routed inside of belt

keeper.

Figure 16

Upper Variable Speed Belt

•

Remove the engine pulley using a 9/16” socket

wrench with a 6” extension. The engine pulley is

located in front of the transmission.

•

Drop the engine pulley down and remove the belt

from around it.

•

Push the idler bracket to the right and remove the

belt. See Figure 16 .

•

Replace belt and reassemble in reverse order.

Fuse Replacement

The fuse is located on the left frame support bracket.

Fuses seldom fail without a reason. If the fuse blows,

the source problem must be corrected or the new fuse

will blow again.

•

Check for loose connections in the fuse holder and

replace holder if necessary. A dead short may be in

the cranking or charging circuit where insulation

may have rubbed through and exposed bare wire.

Figure 15

Deck

Deck Belt

Self-Tapping

Screw

Cover

Belt

Pulley

Idler

Pulley

Belt

Hex

Nut

Lock Washer

& Hex Nut

Keeper “B”

Keeper “A”

Imaginary

Line

Spring

Loaded

Idler

Variable Speed Pulley

Spring

Loaded

Idler

Transmission

Pulley

Deck Belt

Engine Pulley