Section 4: Operation

11

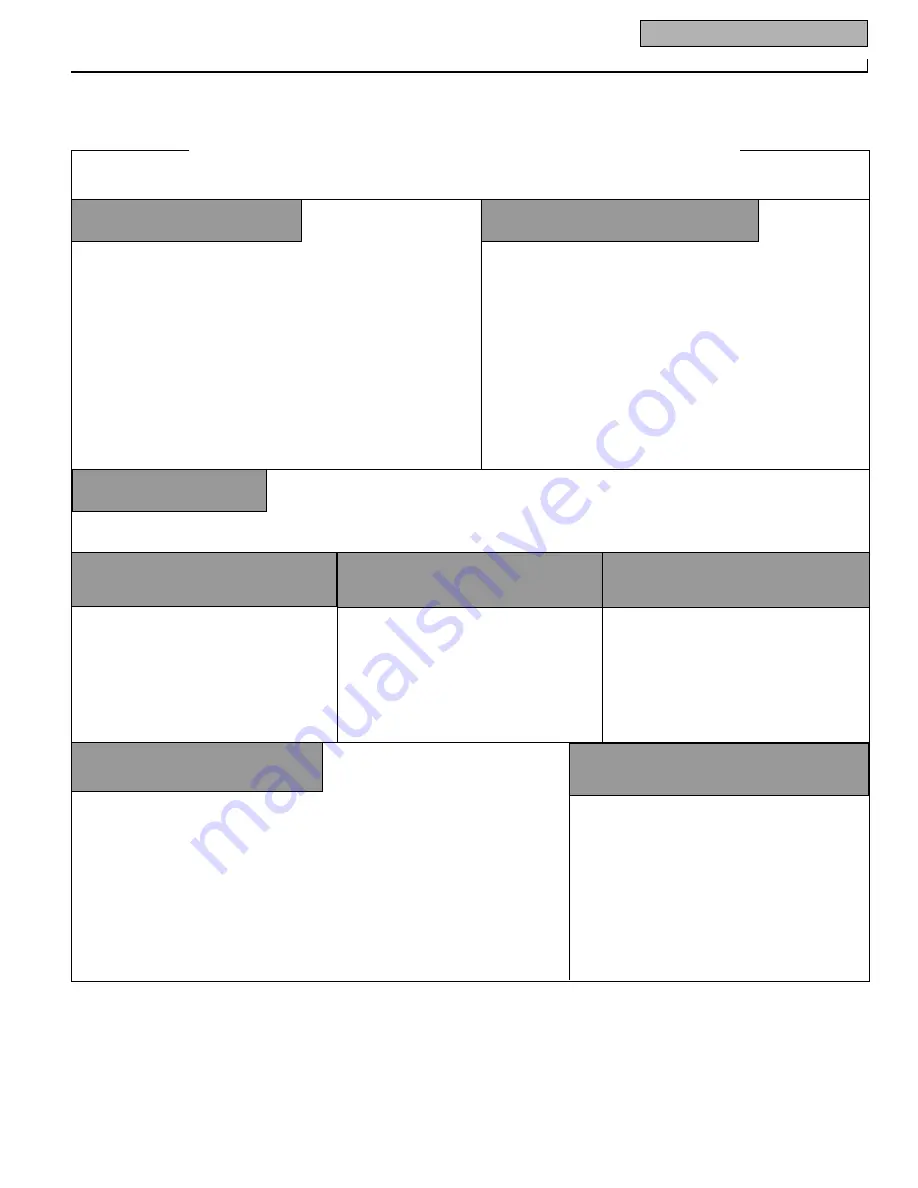

Vary the Throttle Setting

According to Conditions

Use a travel speed that is suitable for the condi-

tions at hand.

For example, you’ll get better trimming and

mowing results at slower walking speeds if the

grass is tall or lush.

Shorter grass or less dense growth can be cut

at faster travel speeds.

Use the Correct

Walking Speed

The majority of trimming and mowing jobs will yield the best results if the

throttle control is set at the fastest speed.

Less demanding jobs (and projects that require very precise cutting) will yield

better results if the engine speed is somewhat reduced. For example, damage

to trees and ornamentals can be avoided by reducing the engine speed, using

the lighter .130" diameter line, and by keeping a safe distance away.

Again, once you begin a particular job and get a “feel” for the conditions, you

will be able to make adjustments for the best possible results.

The trimmer/mower discharges cut

materials to the right side.

For best results, stay on the right side of

unmowed growth as you move along.

Keep the Mowed Side On the

Right While Moving Forward

When the trimmer lines wear to less

than 1/2 their original length, trimming

jobs will take far longer than necessary.

As a general guideline, install new lines

when they wear to 1/2 their original

length.

Clean under the mower deck frequently

to remove any debris buildup. Also

clean around the muffler and on top of

engine.

See the cleaning instructions in Section

5: “Maintenance.”

Clean the Unit On

a Regular Basis

Do Not Let the Trimmer Lines

Become Too Short

For the most precise cutting possible, be sure to select the

appropriate line cutting height and trimmer line size (thickness)

for the conditions at hand.

When mowing, let the cutting head rest lightly on the ground,

without lifting up or pushing down on the handlebars. This tech-

nique allows the cutting head to follow the ground contour

closely, resulting in the most even cut possible.

Also, be sure to ease into heavy growth to prevent overwhelming

the machine.

Grass and most other materials are most efficiently trimmed when dry. But the unit will do a fine

job even with damp or wet materials. When conditions are moist or damp, be sure to clean

debris off the machine regularly to keep cutting efficiency high. And watch your footing!

OPERATING TIPS & TECHNIQUES

Tips for Precision Cutting

When operating on sloping ground, use extreme caution and

common sense to avoid possible injury or property damage.

Do not mow on excessively steep slopes! Avoid slopes if

greater than 15

0

or wherever footing is unsure. If a slope is

difficult to stand on, it is probably too steep to trim or mow.

In this case, it may be wiser to establish a permanent ground

cover on this area.

Do not trim on slopes when the ground is slippery. Trim

across the face of a slope, not up and down. Slow down and

exercise caution when changing direction on slopes.

Use Extreme Caution on Slopes

Trim When Wet or Dry