Drift Cutters

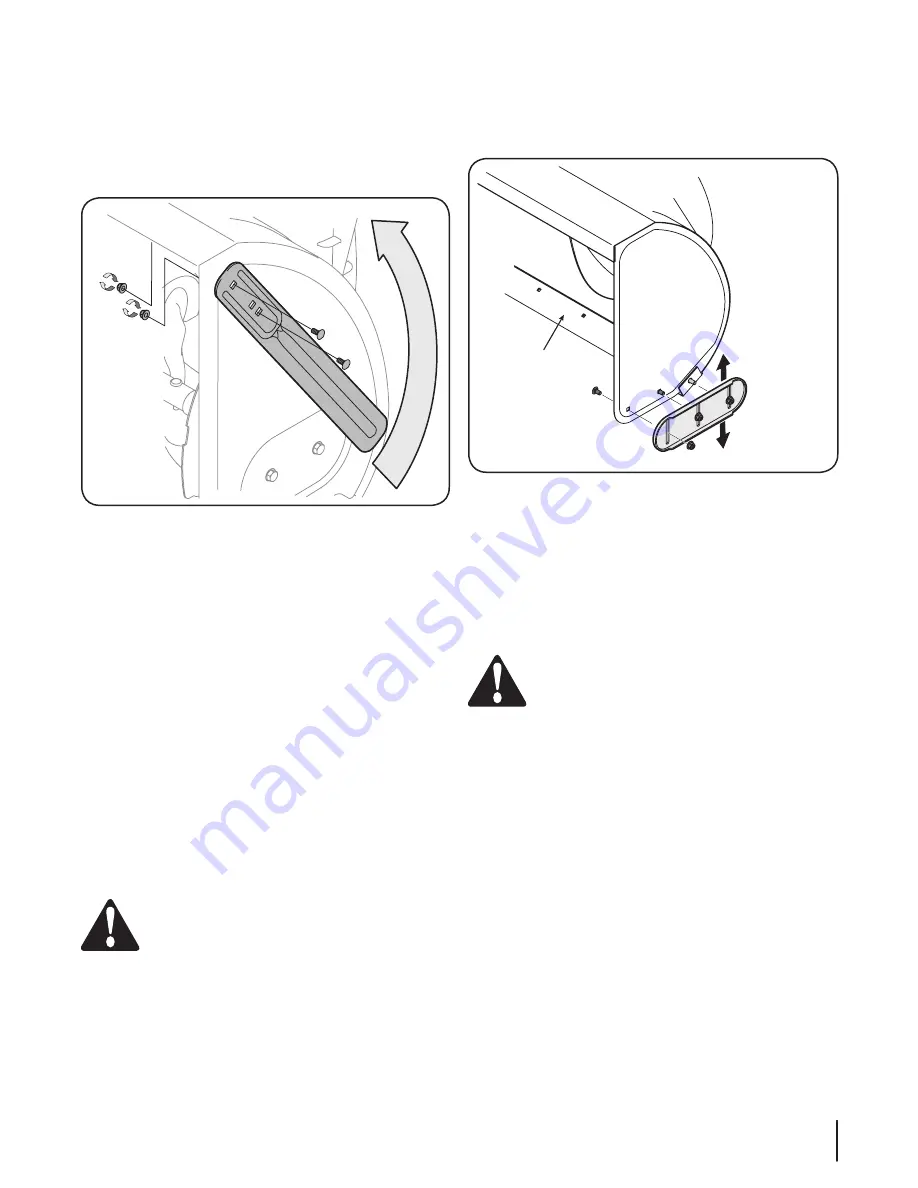

The snow thrower drift cutters are mounted inverted at the

factory for shipping purposes.

1.

Remove the four flange nuts (two on each side) and carriage

bolts. Place drift cutter in upright position and re-secure. See

Figure 3-8.

Figure 3-8

Tire Pressure (Pneumatic Tires)

The tires can be over-inflated for shipping purposes. Check the

tire pressure before operating the snow thrower. Refer to the

tire side wall for manufactures’s recommended psi and deflate or

inflate the tires as necessary.

NOTE:

Equal tire pressure is to be maintained at all times for

performance purposes.

IMPORTANT:

Under any circumstance do not exceed

manufacturer’s recommended psi. Equal tire pressure should be

maintained at all times. Excessive pressure when seating beads

may cause tire/rim assembly to burst with force sufficient to

cause serious injury. Refer to sidewall of tire for recommended

pressure.

Adjustments

Skid Shoes

The snow thrower skid shoes are adjusted upward at the factory

for shipping purposes. Adjust them downward prior to operating

the snow thrower.

CAUTION:

It is not recommended that you operate

this snow thrower on gravel as it can easily pick up and

throw loose gravel, causing personal injury or damage

to the snow thrower and surrounding property.

For close snow removal on a smooth surface, adjust the skid

shoes so that the shave plate on the bottom of the auger

housing is just off the ground.

Adjust the skid shoes to a lower position to raise the shave plate

off the ground when clearing uneven areas, or a gravel driveway.

NOTE:

If you choose to operate the snow thrower on a gravel

surface, keep the skid shoes in position for maximum clearance

between the ground and the shave plate.

To adjust the skid shoes:

1.

Adjust skid shoes by loosening the six (three on each side)

hex nuts, washers, and carriage bolts securing the skid

shoes to the auger housing. Refer to Figure 3-9.

Raise

Shave

Plate

Lower

Shave

Plate

Shave Plate

Figure 3-9

2.

While observing the distance between the shave plate and

the ground, adjust the skids shoes up or down to achieve

the desired shave plate height.

3.

Make certain the entire bottom surface of skid shoes are

against the ground to avoid uneven wear on the skid shoes;

then tighten nuts and bolts securely.

Auger and Drive Control Cables

WARNING!

Prior to operating your snow thrower,

carefully read and follow all instructions below.

Perform all adjustments to verify your snow thrower is

operating safely and properly.

Testing Auger Drive Control

1.

When the auger control is released and in the disengaged

“up” position, the cable should have very little slack. It

should NOT be tight. Refer to Figure 3-10.

2.

In a well-ventilated area, start the snow thrower engine

as instructed in engine operator’s manual. Make sure the

throttle is set in the FAST position.

3.

While standing in the operator’s position (behind the snow

thrower), engage the auger.

4.

Allow the auger to remain engaged for approximately ten

(10) seconds before releasing the auger control. Repeat this

several times.

5.

With the throttle control in the FAST (rabbit) position and

the auger control in the disengaged “up” position, walk to

the front of the machine.

6.

Confirm that the auger has completely stopped rotating

and shows NO signs of motion. If the auger shows ANY

signs of rotating, immediately return to the operator’s

position and shut off the engine. Wait for ALL moving parts

to stop before re-adjusting the auger control.

9

S

ection

3 — A

SSembly

& S

et

-U

p

Summary of Contents for Polar Blast 3310 XP

Page 53: ...Notas 11 53 ...