13

S

ection

6 — M

aintenance

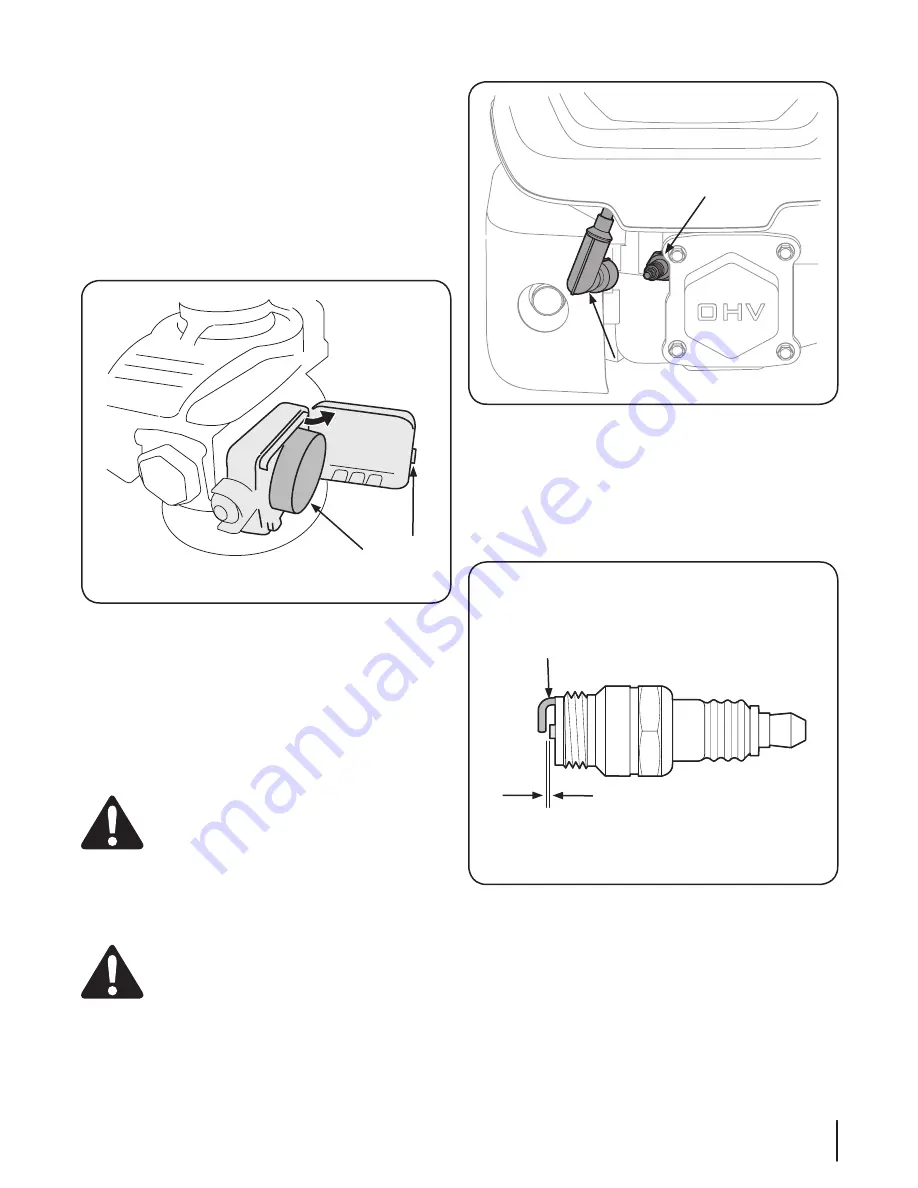

2.

Visually inspect the spark plug. Discard the spark plug

if there is apparent wear, or if the insulator is cracked or

chipped. Clean the spark plug with a wire brush if it is to be

reused.

3.

Measure the plug gap with a feeler gauge. Correct as

necessary by bending side electrode. See Fig. 6-5. The gap

should be set to 0.030 in.

4.

Check that the spark plug washer is in good condition

and thread the spark plug in by hand to prevent cross-

threading.

5.

After the spark plug is seated, tighten with a spark plug

wrench to compress the washer.

Electrode

0.030 in.

Figure 6-5

2.

To clean foam element, remove it from the air filter cover

and wash in a mild liquid detergent and water. Squeeze

or press the foam element to rinse out dirt and water. Do

not twist; this could damage or tear the foam element.

Allow to dry thoroughly before using. DO NOT oil the foam

element.

Single Element Air Filter

1.

Remove the air filter cover by squeezing the front and

back sides to release the tab at the front of the air filter

cover. See Fig. 6-3. Clean foam element or replace when

damaged.

2.

To clean foam element, remove it from the air filter base

and wash in mild liquid detergent and water. Squeeze or

press the foam element to rinse out dirt and water. Do not

twist, this could damage or tear the foam element. Allow to

dry thoroughly before using. OIL the foam element with a

light engine oil.

Spark Plug Service

WARNING:

DO NOT check for spark with spark

plug removed. DO NOT crank engine with spark

plug removed.

To ensure proper engine operation, the spark plug must be

properly gapped and free of deposits.

1.

Remove the spark plug boot and use a spark plug wrench

to remove the plug. See Fig. 6-4.

WARNING:

If the engine has been running, the

muffler will be very hot. Be careful not to touch the

muffler.

Spark Plug

Spark Plug Boot

Figure 6-4

Figure 6-3

Tab

Paper

Element

Summary of Contents for Series 200 World Rear Wheel Tiller

Page 16: ...Notes 16 ...

Page 50: ...16 Notes ...