26

S

ection

7— S

ervice

Changing the Deck Engagement Belt

WARNING!

Shut the engine off and remove key if

so equipped before removing the cutting blade(s)

for sharpening or replacement. Protect your hands

by using heavy gloves when grasping blades and

pulleys.

WARNING!

The V-belts found on your mower are

specially designed to engage and disengage safely.

A substitute (non-OEM) V-belt can be dangerous by

not disengaging completely. For a proper working

machine, use factory approved belts.

All belts on your mower are subject to wear and should be

replaced if any signs of wear are present . To change or replace

the deck engagement belt on your mower, proceed as follows:

1.

Remove the cutting deck from the mower as instructed

earlier in this section.

WARNING!

Avoid pinching injuries. Never place

your fingers on the idler spring or between the belt

and a pulley while removing the belt

2.

Remove the belt cover as instructed earlier in this section.

See Fig. 7-1.

3.

Remove the belt keeper as instructed earlier in this section.

See Fig. 7-2

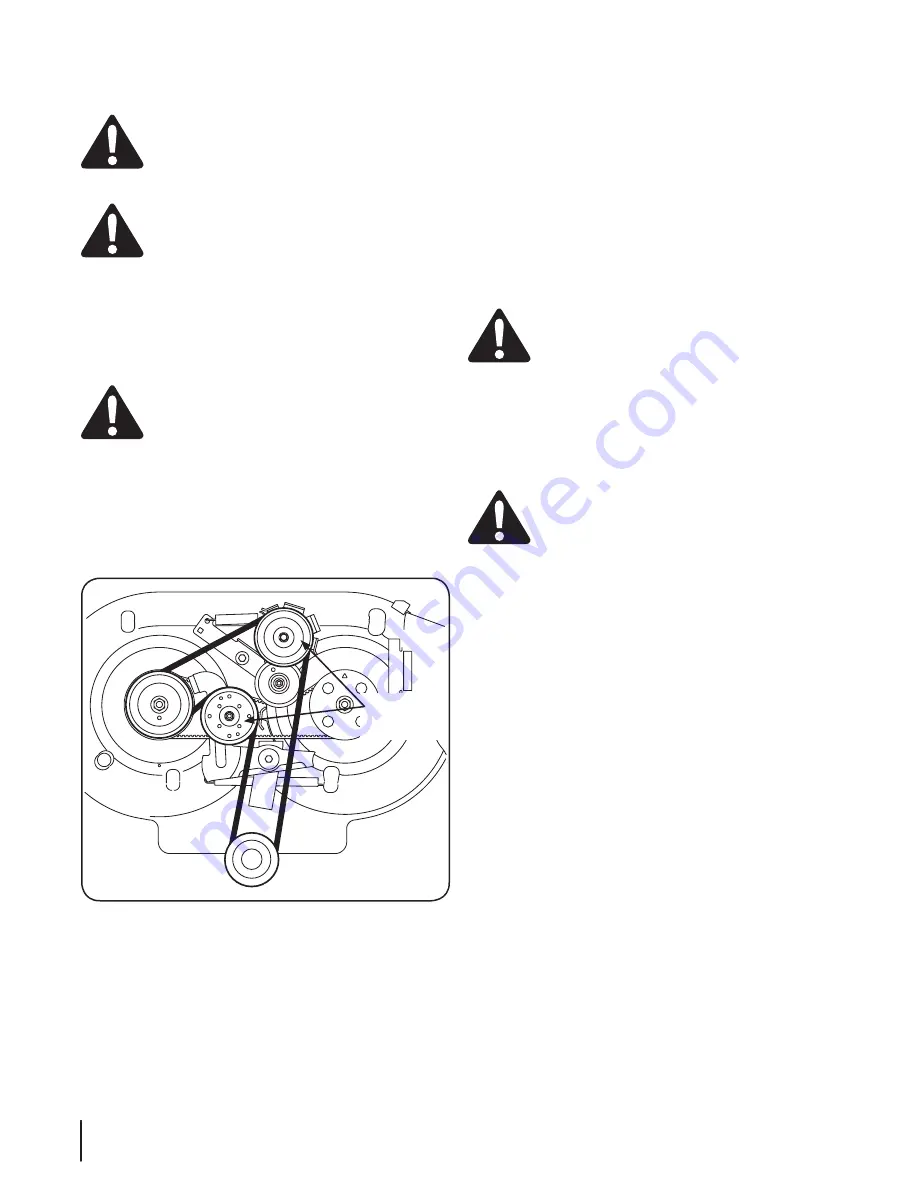

4.

Loosen, but not remove, the nut and bolt which secures

each deck idler pulley. See Fig. 7-8.

5.

Remove the belt from around all pulleys.

6.

Route the new belt as illustrated in Fig. 7-8.

7.

Retighten the nuts and bolts which secure each idler

pulley.

8.

Reattach the belt keeper and belt cover.

Changing the Deck Timing Belt

Several components must be removed and special tools used

in order to change the mower deck’s timing belt. See your

authorized service dealer to have the deck’s timing belt replaced.

Changing the Transmission Drive Belt

Several components must be removed and special tools used in

order to change the mower’s transmission drive belt. See your

authorized service dealer to have the transmission drive belt

replaced.

Fuse (Electric Start Models Only)

WARNING!

Before servicing, repairing, or

inspecting, always disengage blades, stop engine

and remove key to prevent unintended starting.

A fuse is installed in your mower’s wiring harness to protect the

mower’s electrical system from damage caused by excessive

amperage.

If the electrical system does not function, or your mower’s

engine will not crank, first check to be certain that the fuse has

not blown. It is located near the battery.

CAUTION:

Always use a replacement fuse with the

same amperage capacity as the blown fuse.

Deck Idler

Pulleys

Figure 7-8

Summary of Contents for TB WC33 XP

Page 31: ...Notes 11 31...

Page 63: ...Notas 11 63...