8

MAINTENANCE AND REPAIR INSTRUCTIONS

CHECKING THE OIL LEVEL

The importance of checking and maintaining the

proper oil level in the crankcase cannot be

overemphasized. Check oil before each use:

1. Stop the engine and allow oil to drain into

the crankcase.

2. Place the unit on a flat, level surface to get a

proper oil level reading.

3. Keep dirt, grass clippings and other debris

out of the engine. Clean the area around the

oil fill plug before removing it.

4. Remove the oil fill plug.

5. Check the oil level. Oil should be just to the bottom of the threads of the

oil fill hole (Fig. 26).

6. If the level is low, add a small amount of oil to the oil fill hole and recheck

(Fig. 26). Repeat this procedure until the oil level reaches the bottom of the

threads in the oil fill hole.

NOTE:

Do not overfill the unit.

NOTE:

Make sure the O-ring is in place on the oil fill plug when checking

and changing the oil (Fig. 25).

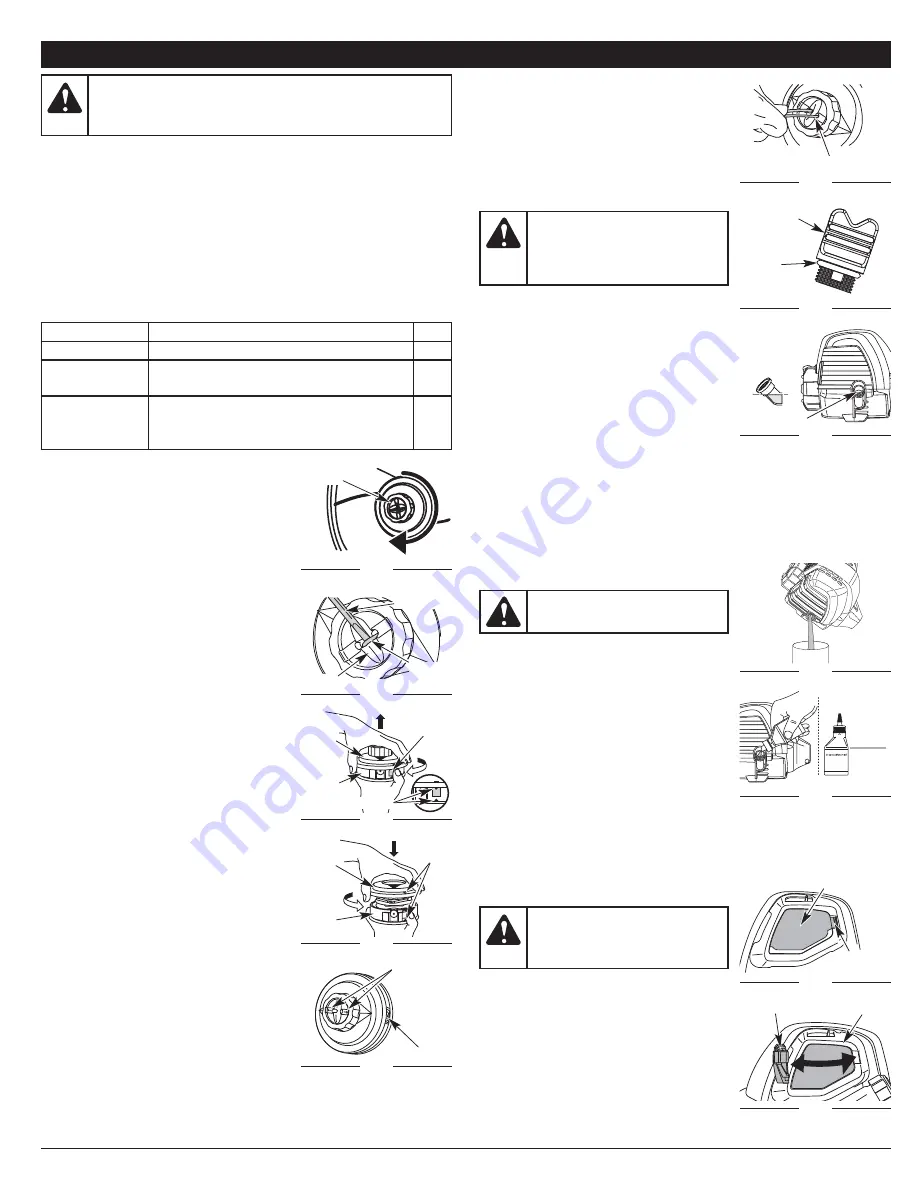

CHANGING THE OIL

Change the oil while the engine is still warm. The

oil will flow freely and carry away more impurities.

1. Remove the oil fill plug.

2. Pour the oil out of the oil fill hole and into a

container by tipping the unit to the side (Fig.

27). Allow ample time for complete drainage.

3. Wipe up any oil residue on the unit and

clean up any oil that may have spilled.

Dispose of the oil according to federal, state

and local regulations.

4. Refill the crankcase with 2.2 fl.oz. (60 ml) of

SAE 30 SF, SG, SH oil.

NOTE:

Use the bottle and spout saved from initial use to measure the correct

amount of oil. The top of the label on the bottle measures approximately

3.4 ounces (100 ml) (Fig. 28). Check the level (Fig. 26). If the level is low,

add a small amount of oil and recheck. Do not overfill (Fig. 26).

5. Replace the oil fill plug.

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Failure to maintain the air filter properly can

result in poor performance or can cause

permanent damage to the engine.

1. Open the air filter cover by pressing the lock

tab in and pulling out on the air filter cover

(Fig. 29 and 30).

2. Remove the air filter (Fig. 31).

3. Wash the filter in detergent and water. Rinse

the filter thoroughly and allow it to dry.

4. Apply enough clean SAE 30 motor oil to lightly coat the filter.

CAUTION:

Wear gloves to prevent

injury when handling the unit.

WARNING:

To avoid serious

personal injury, always turn the unit

off and allow it to cool before you

clean or service it.

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in

the table. These procedures should also be a part of any seasonal tune-up.

NOTE:

Some maintenance procedures may require special tools or skills.

If you are unsure about these procedures take your unit to any non-road

engine repair establishment, individual or authorized service dealer.

NOTE:

Maintenance, replacement, or repair of the emission control

devices and system may be performed by any non-road engine repair

establishment, individual or authorized service dealer.

NOTE:

Please read the California/EPA statement that came with the unit

for a complete listing of terms and coverage for the emissions control

devices, such as the spark arrestor, muffler, carburetor, etc.

WARNING:

To prevent serious injury, never perform

maintenance or repairs with unit running. Always service and

repair a cool unit. Disconnect the spark plug wire to ensure that

the unit cannot start.

REMOVING THE LINE

1. Rotate the bump knob clockwise until all

line is inside the cutting head (Fig. 19).

NOTE:

If the bump knob will not rotate, refer to

Disassembling and Reassembling the

Cutting Head

.

2. Using a flat-head screwdriver, insert the tip

into the line dimple and just under the

exposed portion of the line (Fig. 20).

3. Pull the line straight out until all line is

removed from the cutting head.

Disassembling and Reassembling the

Cutting Head

1. Press the tab inward and rotate the upper

spool cover clockwise until the arrows on the

upper and lower spool covers align (Fig. 21).

2. Remove the upper spool cover.

3. Remove the old trimming line from the

cutting head.

4. Align the arrows on the upper and lower

spool covers. Push the upper and lower

spool covers together. Rotate the upper

spool cover counterclockwise until it locks

into place (Fig. 22).

LINE INSTALLATION

Always use original equipment manufacturer

0.095 in. (2.41 mm) replacement line.

1. Align the arrows on the bump knob with the

spool cover eyelets, if they are not already

(Fig. 23).

2. Using 16 ft. (3.2 m) of 0.095 in. (2.41 mm)

replacement line push both ends of the line

through the holes in the bump knob until they

protrude through the eyelets on both sides of

the cutting head. Continue pulling the line

until approximately 6 ft. (1.5 m) is visible from

both sides of the cutting head. (Fig. 24)

3. Hold the spool cover, turn the bump knob

clockwise to wind the line around the spool

until about 5 in. (12.7 cm) is protruding from

each side of the cutting head. (Fig. 19)

4. Start the unit and bump the cutting head on

the ground until the desired cutting length is

achieved. Excess line will be trimmed off by

the line blade.

NOTE:

If the cutting line ends are pulled into the cutting head or the line

becomes twisted, refer to

Removing the Line

.

FREQUENCY

MAINTENANCE REQUIRED

SEE

Every 10 hours

Clean and oil air filter

p. 8

After 1st 10 hours

Change oil

Check rocker arm to valve clearance and adjust

p. 8

p. 9

Every 40 hours

Change oil

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 8

p. 9

p. 9

WARNING:

To prevent extensive

engine wear and damage to the

unit, always maintain the proper oil

level in the crankcase. Never

operate the unit with a low oil level.

Fig. 19

Fig. 20

Fig. 23

Fig. 24

Fig. 25

Bump

Knob

Flat-Head

Screwdriver

Trimmer

Line

Dimple

Arrows

Eyelet

Trimmer line

O-Ring

Oil Fill Plug

Fig. 26

Fig. 27

Fig. 28

Oil Fill Hole

Add 1.4-1.5 Oz.

(41-44 ml)

Fill

Level

Fig. 29

Fig. 30

Air Filter

Cover Tab

Air Filter Cover

Air Filter Cover

Back Plate

Fig. 21

Upper

Spool

Cover

Fig. 22

Lower

Spool

Cover

Upper

Spool

Cover

Lower

Spool

Cover

Tab

Arrows

Arrows