14

CHECKING THE OIL LEVEL

Inspecting the Oil Level Window

1. Stop the engine and allow it to cool.

2.

Set the unit on a flat, level surface

, such as a workbench or

table. The cutting head shield should hang over the edge so that

the engine is level (Fig. 19).

NOTE:

Failure to keep the engine level may cause the oil to overfill.

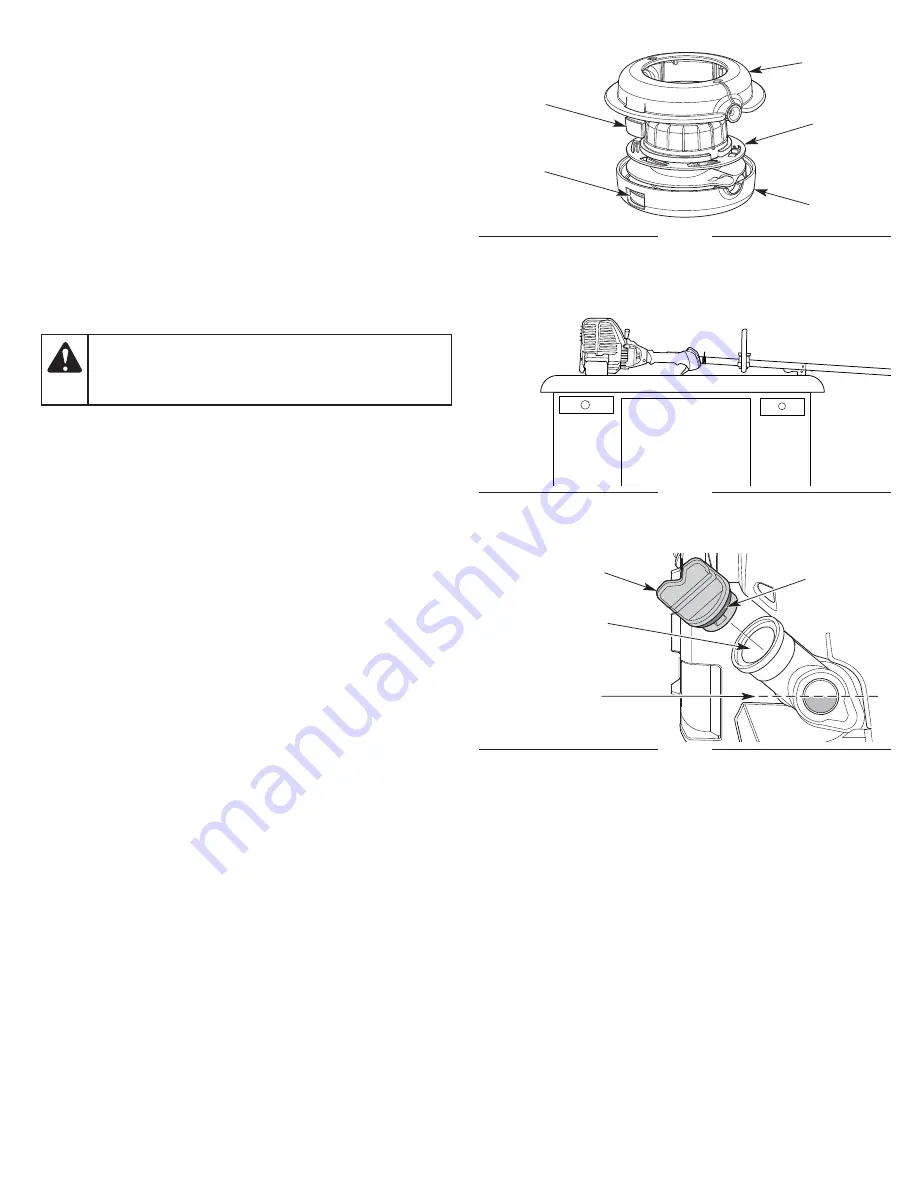

3. Look into the oil level window; use a flashlight if necessary.

The

oil level should fill the window approximately halfway

(Fig.

20). If the oil level is too low, add oil. Refer to

Adding Oil

.

Adding Oil

1. Clean the area around the oil fill plug (Fig. 20) to prevent debris

from entering the oil fill hole.

2. Unscrew the oil fill plug.

3. Add oil to the oil fill hole until the oil level is approximately

halfway up the oil level window (Fig. 20).

NOTE: DO NOT

overfill the crankcase.

4. Wipe up any oil that may have spilled.

5. Reinstall the oil fill plug.

NOTE:

Make sure the O-ring is in place on the oil fill plug (Fig. 20).

WARNING:

OVERFILLING THE CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check the oil level

before each use. The importance of maintaining the proper

oil level cannot be overemphasized.

Fig. 19

Removing Old Trimming Line and Obstructions

If necessary, remove any old trimming line and/or obstructions from

the cutting head.

1. Firmly press in the tabs on the cutting head (Fig. 18).

2. Remove the spool cover (Fig. 18).

3. Remove any old trimming line and/or obstructions.

4. Use a clean cloth to clean the inner reel, outer spool and spool

cover (Fig. 18).

5. Align the tabs on the spool cover with the holes on the outer

spool (Fig. 18). Push the spool cover onto the outer spool until

the tabs securely snap into the holes.

Fig. 20

Oil Fill Hole

Maximum

Oil Level

Oil Fill Plug

O-Ring

Fig. 18

Outer Spool

Inner Reel

Spool Cover

Tab

Hole

Summary of Contents for TB675

Page 19: ...19 NOTES...

Page 39: ...39 NOTAS...