TRU-TURF R52-ELT

Golf Greens Roller Manual

11

TRU-TURF R52-ELT

Golf Greens Roller Manual

12

Fault Finding

Roller will not move one or either way, check

• Batteries are not flat

• Ignition is on

• Chain or Belt are okay

• Sprockets are not worn or slipping on the shaft

• Foot control is operating correctly

• For Sheared Sprocket Keys

Roller will not steer, check

• Woodruff Key is in place and not sheared

• Rod ends are connected to smoothing roller head and

the steering arm

• Rod ends are not broken or seized

• Centre swivel bearing on top centre of each

smoothing roller head has not seized

• Connecting rod are in place and serviceable

Smoothing rollers seized, check

• Bearings are OK and not rough or seized

• Replace if necessary

Rubber drive roller will not rotate, check

• Roller shaft end bearings have not seized

• Broken chain or Belt

• Slipping sprockets

• Accumulated dry debris is not locking the

smoothing rollers. (Clean properly after use)

• Internal bolts securing the coupling to the roller tube

loose or came out

Fault Finding

(b) Remove roller shaft bolts from end plates, remove

rollers from the heads.

(c) Screw a bolt back into the shaft end, knock out one

end bearing, then use the same shaft to knock out

the other end bearing.

(d) Fit new bearings, replace rollers into the heads,

lubricate shaft bolts with an anti seize compound

before installing them. Tighten securely and ensure

rollers rotate freely when fully tightened.

(e) Be sure the spacing washers are fitted to the shaft

ends before installing the rollers into the heads, in

the correct sequence smaller diameter washer first

and the larger diameter washer last.

(f) Sometimes, if the rollers do not rotate freely when

installed use a soft headed hammer to hit the

securing bolts on each end of the head, this will seat

all parts and allow the roller to rotate freely.

(g) If the rods are removed or lengths altered ensure

they are correctly adjusted so that the three heads

are parallel to each other when in the straight

ahead position. Adjust if necessary.

Changing transmission oil

• Refer to the manufacturers recommendations.

Contour following drive roller

• Do not disassemble this unit unless you correctly mark

the coupling to tube alignment.

• This is important when re-assembling to ensure the

correct balance is achieved.

• Damage to either section of this roller means a

complete drive roller assembly is required, the supply

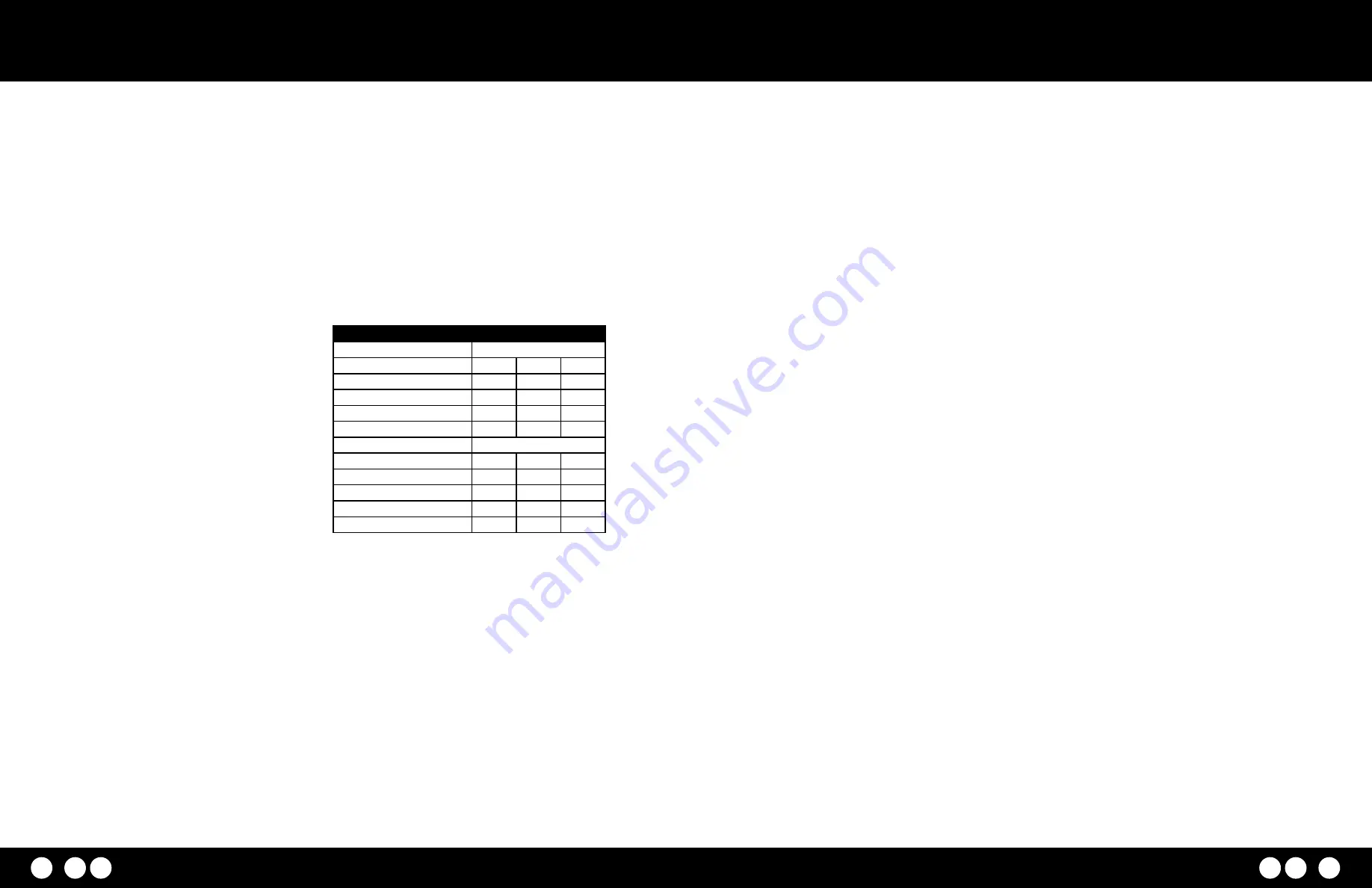

Description

Pre-Delivery

Pre-Operating

12 Monthly

Transmission Oil

As per manufacturers Handbook

Lubricate drive chain with WD40 or equivalent (If fitted)

√

√

Check Tires Max 15 P.S.I.

√

√

Check Smoothing Roller Bearing

√

√

Check Drive Roller Bearings

√

√

Check for loose Nuts and Bolts

√

√

Renew Transmission Oil

As per manufacturers Handbook

Renew Smoothing Roller Bearings

√

√

Renew Drive Roller Bearings

√

√

Renew Chain Tensioner Sprocket Bearings (If fitted)

√

√

Renew Drive Chain (If fitted)

√

√

Replace Trailer Strut

√

of individual components is not recommended or

available.

Ongoing Maintenance, Lubricant and Replacement

Schedule (below)

Note.

Areas indicated with a * need to be changed

when defective or as required. This may be before the

recommended replacement schedule. Please replace all

parts as necessary.

Maintenance