58

11

» Y081564 - (EN - REV. 003) | JUNE 2022

Do not use grease containing molybdenum

disulphide. Use only actuators which are recommended

by the vehicle manufacturer.

It is not allowed to reuse the nuts of the brake chamber

(18).

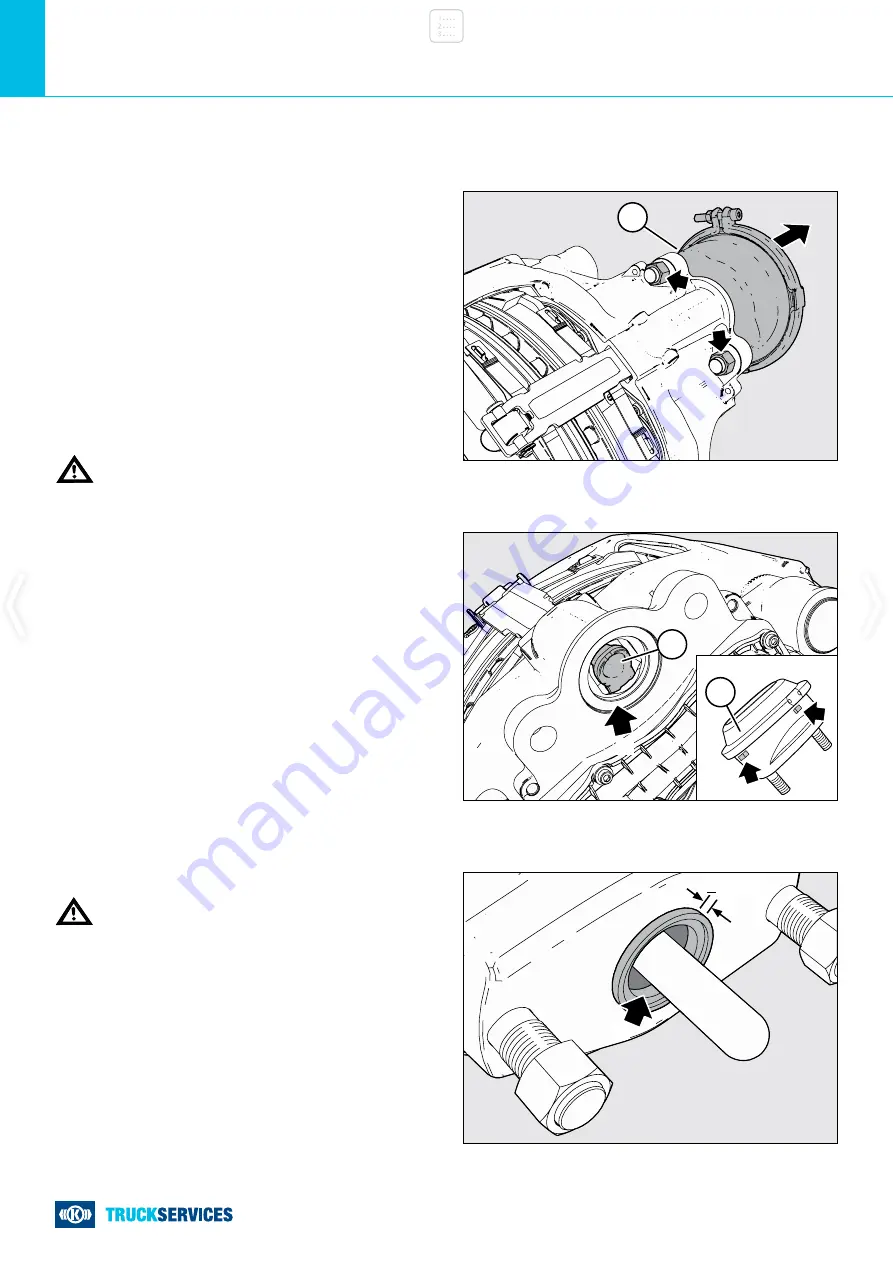

11.1 Removal of Knorr-Bremse Brake Chamber

11.1.1 Disconnect air connection from brake chamber (18) –

take care, air connection must be free of air pressure!

11.1.2 Unscrew brake chamber mounting nuts and remove

brake chamber (18) (see arrows in Fig.).

11.2.3. The seal, as well as the push rod area of the brake

chamber (18) (see arrow

C

) must be clean and free of

lubrication.

The seal must not show any signs of damage.

Note, if the brake chamber’s seal protrudes less than

3 mm

the brake chamber must be replaced (see Fig.).

Note:

All references to brake actuators (brake chambers and

spring brakes) in this section refer to Knorr-Bremse brake

actuators. For other brake actuator manufacturers, follow their

respective instructions.

11.2 Fitting of Knorr-Bremse Brake Chamber

Note:

New brake chambers (18) have drain plugs installed (see

arrow

A

). Remove lowest plug (as viewed when brake chamber

is installed). All other drain holes should be plugged (refer to the

vehicle manufacturer’s recommendations).

11.2.1 The sealing surface and the flange surface (see Fig.

arrow

B

) must be:

- free from dust and corrosion

- free from damage

- flat

Take care that no dirt enters the brake caliper!

11.2.2

Before fitting the new brake chamber, the

spherical cup (19) of the lever and the sealing surface of the

caliper must be greased with white grease (Part No. II14525,

K093430 or II32868).

11.1.2 - Brake chamber removal

11.2.1 - 11.2.2 - Check seal and flange surface of caliper,

grease spherical cup and flange surface

11.2.3 - Check seal, min.

3 mm

11. BRAKE ACTUATOR REPLACEMENT

C

C

> 3 mm

AA

B

B

19

18

18