1

Congratulations and thank you for buying a TRUCK-

FORCE® portable extractor. The TruckForce is designed to

give you truckmount performance in a portable machine that

is versatile to use and easy to transport. Years of experience,

engineering, planning, and practical know-how has gone into

the design and manufacture of the TruckForce. We take a

great deal of pride in TruckForce and want you to be com-

pletely satisfied with your purchase. Please take the time to

read this manual before operating the machine—it will be

time well spent.

SETUP AND OPERATION

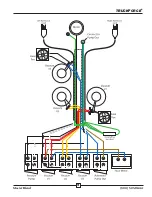

ELECTRICAL CONNECTIONS

Plug electrical cords into grounded wall outlets. Truck-

Force is designed to run on a 15 AMP and a 20 AMP circuit

(the left hand cord). You will normally find 20 AMP separate

circuits in the kitchen and in bathrooms. Never remove the

ground plug from the end of the cord. If a circuit breaker trips

during operation, reset the breaker and move electrical cord

to different outlet and resume operation. When cords are

plugged into “live” receptacles, the control switches will

glow. If the lights on the switches do not glow, this indicates

that the wall receptacle may be dead. Simply move the cord to

a different outlet.

WARNING:

The TruckForce is designed for use

with water based cleaning solutions, such as, low

foaming detergents or acid rinses. NEVER USE DRY

SOLVENT SOLUTIONS! The use of dry solvents in

your TruckForce will void the warranty.

AUTOMATIC CHEMICAL FEED

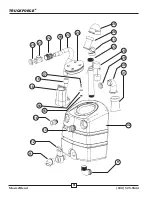

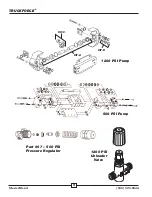

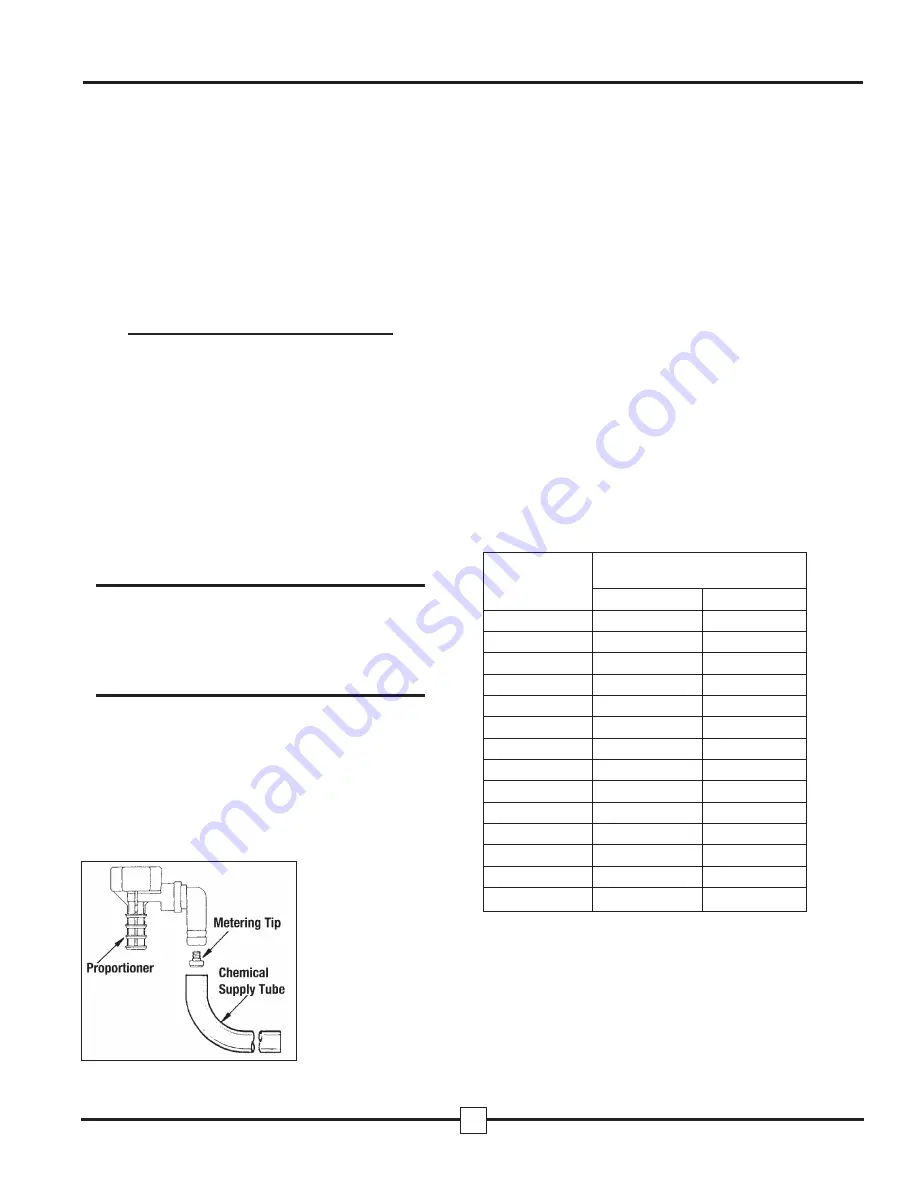

Chemical Metering:

The TruckForce may be equipped with

an automatic water fill/chemical feed metering system. As the

solution tank fills with water, cleaning concentrate is drawn

into the solution tank at a designated rate via a metering tip. A

complete set of metering tips is included.

To adjust the amount

of cleaning concentrate

being drawn, simply

remove the plastic sup-

ply

tube

from

the

chemical feed metering

valve (see Figure 1).

Unscrew the colored

metering

tip

and

replace with the tip

that corresponds to the

portable dilution ratio

for your cleaning product (refer to Figure 2). Reconnect the

plastic supply tube.

Liquid Concentrates:

TruckForce comes with the purple

metering tip installed at the factory. This tip is rated for .25

oz. of chemical per gallon of water, which is a standard dilu-

tion ratio for the most popular liquid cleaning products on the

market. Refer to your product’s dilution ratio for portable

extractors, and select the proper metering tip from Figure 2

(“Liquid Concentrated Dilution Ratio”).

Powder Concentrates:

For powdered cleaning detergents,

a liquid concentrate must be made. Combine two (2) cups of

powder in a one gallon solution jug. Fill the jug with water up

to the one gallon mark. Use the tip that corresponds to the

portable dilution ratio for your powdered cleaning product

(refer to Figure 2, “Powder Concentrated Dilution Ratio”).

Fresh Water Rinse:

For fresh water rinsing simply leave

the chemical supply tube in the solution tank.

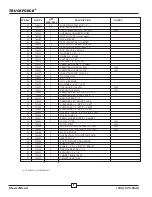

Manual Filling:

To use the TruckForce without the auto-

matic filling system, simply pre-mix your solution in a bucket

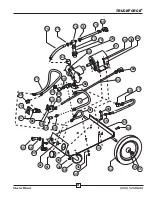

of water, and pour into the solution tank. See Figure 3 for a

detailed break-down of the chemical feed system.

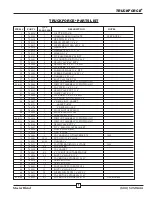

Figure 2

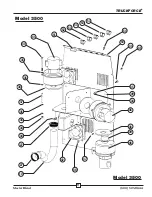

Setup:

Inside the solution tank is a bottle float suspended

on a chain. The length of the chain determines the level of

solution in the tank and can be adjusted. Check the chemical

feed supply foot valve for debris, and clean if necessary.

Insert the line into the cleaning concentrate so that it touches

the bottom of the bottle. Set cleaning concentrate in the solu-

tion holder/pouring funnel provided.

TRUCKFORCE

®

MasterBlend

(800) 525-9644

Figure 1

Metering Tip Replacement

Concentrated Dilution

Ratio (oz/gal)

Tip Color

Liquids

Powders

Clear

0.25

—

Purple

0.50

—

Yellow

1.00

—

Green

1.50

—

Pink

2.00

0.25

Turquoise

3.20

0.40

Black

4.00

0.50

Gray

5.00

0.63

Red

6.50

0.81

Blue

8.00

1.00

Brown

10.50

—

White

13.00

—

Orange

16.00

—

None

35.00

—

Metering Tip Dilution Ratios