5

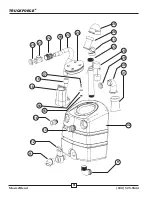

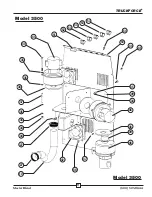

VAC SHUT OFF

The TruckForce utilizes a ball float shutoff system, which

shuts off the flow to the vacuum motors when solution

reaches the appropriate level to activiate the ball shutoff. This

shutoff has been designed to protect the vacuum motors from

excess water entering the vacuum motors

provided that the

owner is utilizing a defoamer chemical to prevent foam

and moisture from entering the vacuum stack and,

therefore, the vacuum motors.

Twist off the ball assembly from the stand pipe, and clean

the screen. It may be rinsed with water. This screen should

be cleaned frequently if the TruckForce is being operated in

an environment which has an abnormal buildup of lint and

debris, such as cleaning newly installed carpet. Loss of vac-

uum is most normally associated with lint and hair buildup in

the waste filter bag and the float ball shutoff assemble at the

top of the vacuum stand pipe.

AUTO PUMP-OUT

The Automatic Pump-Out system is capable of handling

most debris that passes through the waste filter bag. How-

ever, for optimum performance, keep the waste tank clean

and remove debris from the filter screen of the pump-out.

This should be done on a daily basis, or as needed, depending

upon use, and amount of debris.

Every two weeks, run the pump-out with a full tank of

clean water, to insure that debris and lint are not accumulat-

ing in the base of the pump.

To service the pump-out more thoroughly, unhook the vac-

uum cuff, cut the zip tie around the looped electrical cord,

and lift it out of the waste tank. Unsnap the screen from the

bottom, clean the screen, and clean out the area inside.

If necessary, remove the six screws holding the base to the

motor housing, and clean the base. If the impeller is removed

make sure that a spacing of .050” with shaft pushed toward

housing is maintained when reassembled.

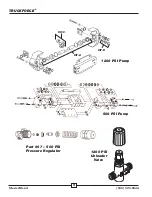

WAND JETS

Remove jets and visually check for wear and debris. Water

or compressed air is best for cleaning—NEVER use a metal

object to remove debris, as it may damage the jet orifice. If

excessive wear is apparent, the jet should be replaced. If the

wand is equipped with jet screens, those should be cleaned by

rinsing with water. Hook up the wand to machine, and check

jet alignment.

FLUSH SOLUTION SYSTEM

At least once a month, the TruckForce, hoses, and tools

should be flushed to remove alkaline residues. Follow the

steps on page 8 of the “Recommended Procedure for Stor-

age,” using a solution of one part warm water with three

parts white vinegar, in place of the antifreeze solution. Then,

repeat the steps using two gallons of fresh water.

WD-40 VAC MOTORS

Should moisture ever enter the vacuum motors, completely

drain the waste tank, open the waste tank lid, remove the vac

shut off ball assembly, turn on all vacuum motors, and spray

a five second burst of WD-40 into the standpipe. Continue to

run the vacuum motors for at least three minutes.

To prevent moisture from damaging the vacuum motors dur-

ing storage, empty the waste tank and store with the lid open.

TRUCKFORCE

®

MasterBlend

(800) 525-9644