ASSEMBLY

TRUE treadmills are shipped in two pieces:

the pedestal assembly (which includes the

control console) and the base.

Instructions for assembling the unit:

1. Remove the protective packaging

materials. N

NO

OT

TE

E:: Do not lift the treadmill

by the motor when removing from carton!

2. Lay pedestal on deck as shown. (Fig. 1)

3. Feed wire harness through reusable wire

ties from left to right. (Fig. 2)

4. Tighten wire ties and tuck excess tie down

between motor and PWM board. (Fig.2)

N

NO

OT

TE

E:: Do not cut off excess wire tie.

These are reusable.

5. Raise top of pedestal into place.

6. Install three of the enclosed screws with lock

washers on each side, then tighten all six

screws. (Fig. 3)

PARTS INCLUDED:

1

1 -

- A

AL

LL

LE

EN

N W

WR

RE

EN

NC

CH

H

6

6 -

- S

SC

CR

RE

EW

WS

S

6

6 -

- S

ST

TA

AR

R W

WA

AS

SH

HE

ER

RS

S ((L

LO

OC

CK

K W

WA

AS

SH

HE

ER

RS

S))

1

1 -

- O

OW

WN

NE

ER

RS

S M

MA

AN

NU

UA

AL

L

1

1 -

- W

WA

AR

RR

RA

AN

NT

TY

Y C

CA

AR

RD

D

1

1 -

- H

HE

EA

AR

RT

T R

RA

AT

TE

E T

TR

RA

AN

NS

SM

MIIT

TT

TE

ER

R W

WIIT

TH

H

S

ST

TR

RA

AP

P ((H

HR

RC

C M

MO

OD

DE

EL

LS

S O

ON

NL

LY

Y))

IIM

MP

PO

OR

RT

TA

AN

NT

T:: Do not operate unless all six

screws are fastened securely. Be sure

screws and lock washers thread into the

holes in pedestal. Reverse procedure

whenever removing the pedestal. Remove

pedestal console only while treadmill is at

zero grade and unplugged.

E

EL

LE

EC

CT

TR

RIIC

CA

AL

L R

RE

EQ

QU

UIIR

RE

EM

ME

EN

NT

T:

Your TRUE treadmill requires a

a d

de

ed

diic

ca

atte

ed

d

1

12

20

0 V

VA

AC

C 2

20

0 a

am

mp

p g

grro

ou

un

nd

de

ed

d o

ou

uttlle

ett c

ciirrc

cu

uiitt..

W

WA

AR

RN

NIIN

NG

G:: Do not use an extension cord or

an ungrounded outlet. The ground helps

prevent electrical damage to your treadmill and

enhances your safety by preventing shock.

This grounded outlet is critical for the HRC

system to function properly. N

NO

OT

TE

E:: Units

produced for use outside of the U.S.A. will have

voltage indicated on the identification tag.

BELT ADJUSTMENTS

Your treadmill’s running belt has been

properly aligned at the factory. However,

when the treadmill is used on an uneven

surface, please follow these instructions:

P

PR

RE

EF

FE

ER

RR

RE

ED

D M

ME

ET

TH

HO

OD

D

Level the treadmill by placing shims 1/8” to

3/8” thick under the front wheel and rear

shock absorber on one side. N

NO

OT

TE

E:: This

method will provide extended belt life by

keeping both rollers parallel. Adjusting the

belt tracking by using the roller bolts will

cause the belt to stretch on one side.

Assembly & Belt Adjustment

1-4

Learning The Basics

1-3

SETTING UP YOUR

TREADMILL

Place your treadmill on a clean, level surface.

Make sure the electrical cord easily reaches a

grounded three-pronged outlet and has

enough slack to allow the deck to incline

unhindered by the cord. Do not allow the

treadmill assembly to rest on the cord.

Although your treadmill is designed to

operate on most carpeted surfaces, some

deeply padded or heavy shag carpets can

cause damage to the unit. To prevent

damage to your treadmill or carpet, have

someone stand on the deck and make sure

the treadmill belt doesn’t touch the carpet at

any point.

Your TRUE treadmill is designed for indoor

use only. Always keep the control panel out of

direct sunlight.

IMPORTANT ELECTRICAL

REQUIREMENTS

Your True treadmill requires a d

de

ed

diic

ca

atte

ed

d

120 VAC 20 amp grounded outlet circuit.

W

WA

AR

RN

NIIN

NG

G:: D

Do

o n

no

ott u

us

se

e a

an

n e

ex

xtte

en

ns

siio

on

n c

co

orrd

d o

orr

a

an

n u

un

ng

grro

ou

un

nd

de

ed

d o

ou

uttlle

ett.. T

Th

he

e g

grro

ou

un

nd

d h

he

ellp

ps

s

p

prre

ev

ve

en

ntt e

elle

ec

cttrriic

ca

all d

da

am

ma

ag

ge

e tto

o y

yo

ou

urr ttrre

ea

ad

dm

miillll

a

an

nd

d e

en

nh

ha

an

nc

ce

es

s y

yo

ou

urr s

sa

affe

etty

y b

by

y p

prre

ev

ve

en

nttiin

ng

g

s

sh

ho

oc

ck

k..

A

A G

GR

RO

OU

UN

ND

DE

ED

D O

OU

UT

TL

LE

ET

T IIS

S C

CR

RIIT

TIIC

CA

AL

L

F

FO

OR

R T

TH

HE

E H

HR

RC

C S

SY

YS

ST

TE

EM

M T

TO

O F

FU

UN

NC

CT

TIIO

ON

N

P

PR

RO

OP

PE

ER

RL

LY

Y..

T

TH

HE

E B

BA

AS

SIIC

CS

S

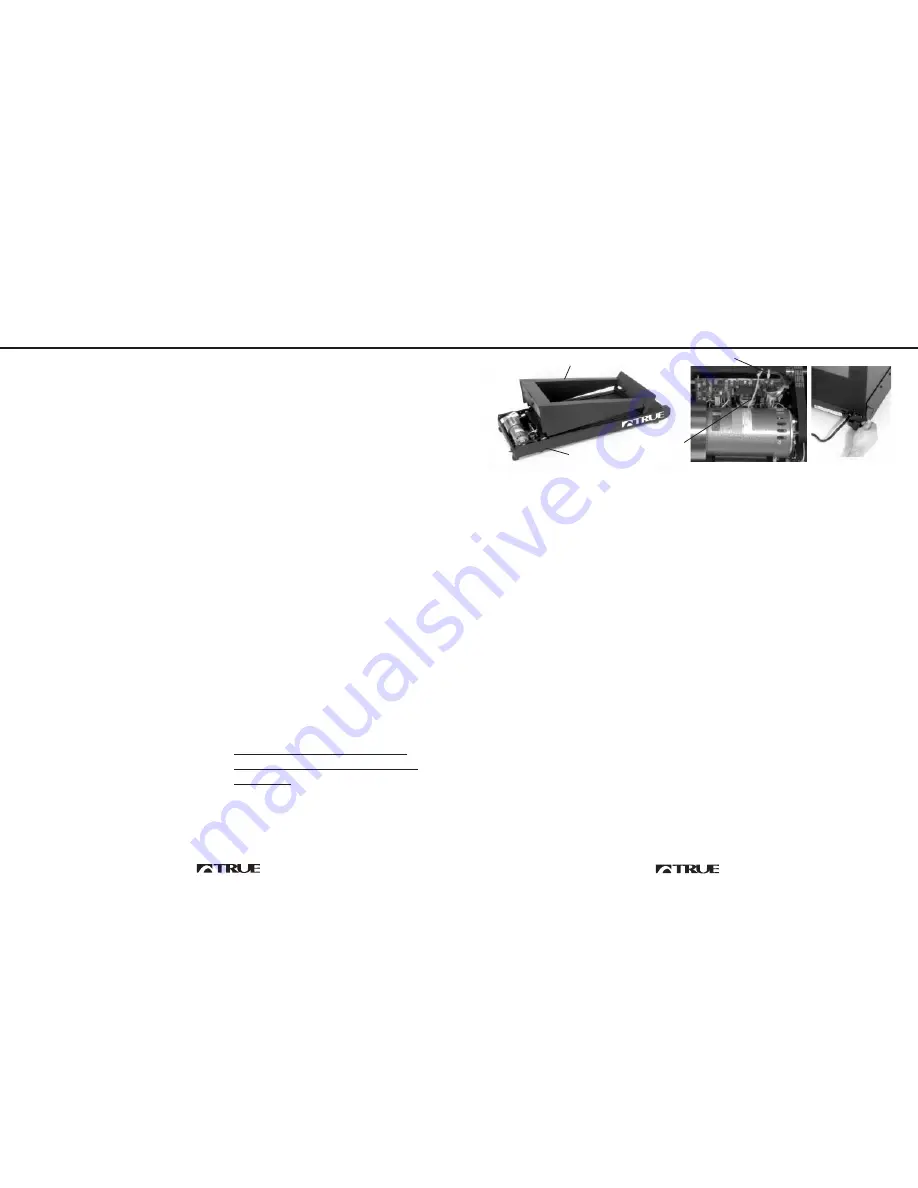

Your treadmill is made up of two main sections: the base and

the pedestal.

The base of the treadmill consists of a metal frame, a

shock-absorbing deck system and a powerful

continuous-duty horsepower DC motor. The motor powers

a pulley system which moves the running belt over the deck.

(See figure 1, page 1-4)

The pedestal mounts on the top of the frame. It places the

displays, information readout and touch keys within easy sight

and reach.

(See figure 1, page 1-4)

Fig. 1

Fig. 3

Fig. 2

PEDESTAL

BASE

1

2

Summary of Contents for 600 Series

Page 28: ...Troubleshooting Flowcharts Troubleshooting Flowcharts 3 19 3 20 ...

Page 29: ...Troubleshooting Flowcharts Troubleshooting Flowcharts 3 22 3 21 ...

Page 30: ...Troubleshooting Flowcharts Troubleshooting Flowcharts 3 24 3 23 E5 SENSOR E2 OVERSPEED E5 ...

Page 31: ...Troubleshooting Flowcharts Troubleshooting Flowcharts 3 26 3 25 ...