4

TRUE

gdim

www

.

truemfg

.

com

230 Volts Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

5

14 14 14 14 14 14 14 14 14 14 14 14

6

14 14 14 14 14 14 14 14 14 14 14 12

7

14 14 14 14 14 14 14 14 14 14 12 12

8

14 14 14 14 14 14 14 14 14 12 12 12

9

14 14 14 14 14 14 14 14 12 12 12 10

10

14 14 14 14 14 14 14 12 12 12 10 10

12

14 14 14 14 14 14 12 12 12 10 10 10

14

14 14 14 14 14 12 12 12 10 10 10 8

16

14 14 14 14 12 12 12 10 10 10 8 8

18

14 14 14 12 12 12 10 10 10 8 8 8

20

14 14 14 12 10 10 10 10 10 8 8 8

25

14 14 12 12 10 10 10 10 8 8 6 6

30

14 12 12 10 10 10 8 8 8 6 6 6

35

14 12 10 10 10 8 8 8 8 6 6 5

40

14 12 10 10 8 8 8 6 6 6 5 5

50

12 10 10 8 6 6 6 6 6 5 4 4

60 12

10 8 6 6 6 6 6 5 4 4 3

70 10

10 8 6 6 6 5 5 4 4 2 2

80 10 8 8 6 6 5 5 4 4 3 2 2

90 10 8 6 6 5 5 4 4 3 3 1 1

100 10 8 6 6 5 4 4 3 3 2 1 1

115 Volt s Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

2

14 14 14 14 14 14 14 14 14 14 14 14

3

14 14 14 14 14 14 14 14 14 14 14 12

4

14 14 14 14 14 14 14 14 14 12 12 12

5

14 14 14 14 14 14 14 12 12 12 10 10

6

14 14 14 14 14 14 12 12 12 10 10 10

7

14 14 14 14 14 12 12 12 10 10 10 8

8

14 14 14 14 12 12 12 10 10 10 8 8

9

14 14 14 12 12 12 10 10 10 8 8 8

10

14 14 14 12 12 10 10 10 10 8 8 8

12

14 14 12 12 10 10 10 8 8 8 8 6

14

14 14 12 10 10 10 8 8 8 6 6 6

16

14 12 12 10 10 8 8 8 8 6 6 6

18

14 12 10 10 8 8 8 8 8 8 8 5

20

14 12 10 10 8 8 8 6 6 6 5 5

25

12 10 10 8 8 6 6 6 6 5 4 4

30 12

10 8 8 6 6 6 6 5 4 4 3

35 10

10 8 6 6 6 5 5 4 4 3 2

40 10 8 8 6 6 5 5 4 4 3 2 2

45 10 8 6 6 6 5 4 4 3 3 2 1

50 10 8 6 6 5 4 4 3 3 2 1 1

WIRE GAUGE CHART

LOCATING

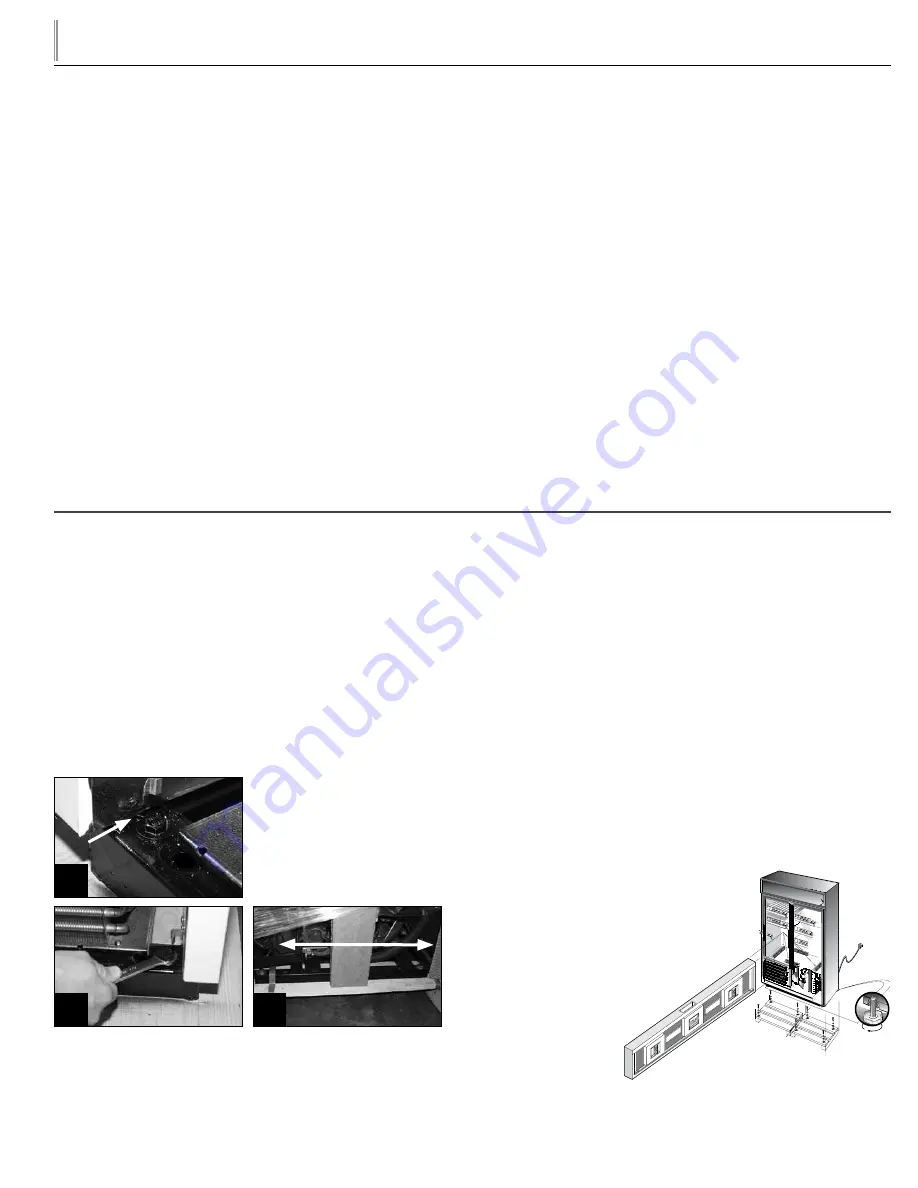

A. Remove louver from the front of cabinet and backguard (if

applicable) from rear of cabinet.

B. Skid bolts are located in each of 4 corners inside cabinet

bottom. (See photo A).

C. Remove skid bolts. (See photo B).

D. Cut straps if applicable. (See photo C).

E. Carefully lift cabinet off of skid.

F. Appliance tested according to the climate classes 5 and 7 for

temperature and relative humidity.

LEVELING

A. Set unit in its final location. Be sure there is adequate ventilation

in your room. Under extreme heat conditions, (100°F+,

38°C+), you may want to install an exhaust fan.

WARNING: WARRANTY IS VOID IF VENTILATION IS

INSUFFICIENT.

B. Proper leveling of your TRUE cooler is critical to operating

success (for non-mobile models). Effective condensate removal

and door operation will be effected by leveling.

C. The cooler should be leveled front to back and side to side with

a level.

D. Ensure that the drain hose or hoses are positioned in the pan.

E. Free plug and cord from inside the lower rear of the cooler

(do not plug in).

F. The unit should be placed close enough to the electrical supply

so that extension cords are never used.

WARNING: CABINET

WARRANTIES ARE VOID IF OEM

POWER CORD IS TAMPERED WITH.

TRUE WILL NOT WARRANTY ANY

UNITS THAT ARE CONNECTED

TO AN EXTENSION CORD.

P

NEPCO/CENTRALA

B

12

27

-5

REMO

VE CO

VER MAKE

PO

WE

R CONNECT

IO

N

Removing skid from bottom

of cabinet.

A

B

C