CHAPTER

4

: CARE & MAINTENANCE

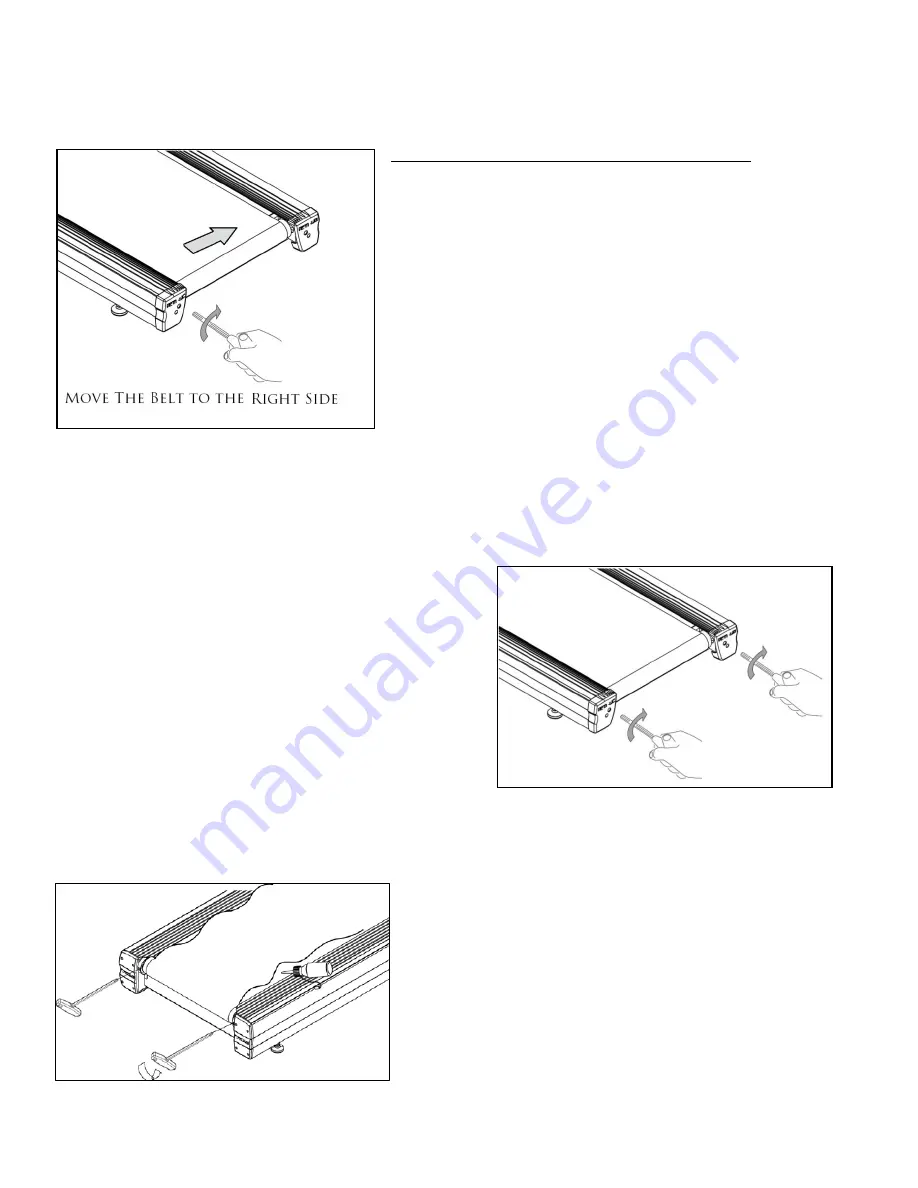

RUNNING BELT ALIGNMENT (continued):

If the running belt is too far to the left side:

•

Locate the belt adjustment bolts in the rear end caps of the

treadmill. (To determine left and right, stand at the rear of the

treadmill and face the display).

•

Using the appropriate size Allen wrench or socket turn the

LEFT adjustment bolt clockwise ¼ turn.

•

Turn the treadmill on and start the belt at 3mph keeping off

the unit.

•

Allow 2 minutes for the belt to adjust itself.

•

Repeat the above steps if additional adjustment is necessary.

TENSIONING THE RUNNING BELT:

If there is a slipping or jerking sensation when running on the treadmill, the running belt may require tightening. In most

cases the belt has stretched from use. Tensioning the belt takes a few simple adjustments. If you are unsure about this

procedure, call the TRUE Service Department.

•

Locate the belt adjustment bolts in the rear end caps of

the treadmill.

•

Using the appropriate size Allen wrench or socket turn

BOTH adjustment bolts clockwise ¼ turn.

•

Turn the treadmill on and start the belt and check if the

slipping continues. Repeat the above steps if additional

adjustment is necessary.

TREADMILL LUBRICATION:

For commercial use over 20 hours per week, TRUE recommends lubricating every three months.

•

Loosen the belt adjustment bolts in the rear end caps.

•

Lift the belt and apply the lubricant to the center of the deck.

•

Center and re-tension the belt using the directions above.

•

Walk on the treadmill at 2MPH for about 60 seconds to

spread the lubricant evenly through the belt and deck.

*Please contact your dealer or visit www.truefitness.com to obtain the

proper lubricants.

Truefitness.com / 800.426.6570 / 636.272.7100

24

Summary of Contents for TC400

Page 10: ...CHAPTER 1 SAFETY INSTRUCTIONS Truefitness com 800 426 6570 636 272 7100 6 ...

Page 39: ...CHAPTER 6 ADDITIONAL INFORMATION WIRING DIAGRAMS Truefitness com 800 426 6570 636 272 7100 35 ...

Page 40: ...CHAPTER 6 ADDITIONAL INFORMATION WIRING DIAGRAMS Truefitness com 800 426 6570 636 272 7100 36 ...