............ www.truemfg.com ............

............ www.truemfg.com ............

True Food Service Equipment, Inc.

True Food Service Equipment, Inc.

6

6

6

6

INSTALLATION / OPERATION INSTRUCTIONS

INSTALLATION / OPERATION INSTRUCTIONS

DEFROST TIME CLOCK OPERATION

(Grasslin Timer)

NOTE:

Defrost timer will need to be

set at current time of day

before plugging unit into

power supply. The defrost

times have been set from the

factory. If you want to change

defrost times please read

through the defrost timer

instructions.

RECOMMENDED DEFROST

SETTINGS:

True Manufacturing has factory set your

defrost time clock to a recommended

time and duration defrost scenario. All

TSID and TDBD will require routine

defrost. Your True equipment has been

designed for three defrost periods (6:00

a.m., 2:00 p.m. and 10:00 p.m.). If you

decide to deviate from these defrost

time settings please follow the proce-

dures for adjustment below.

REQUIRED TOOLS:

•

Phillips Screwdriver

•

1/4” Nut Driver or Socket

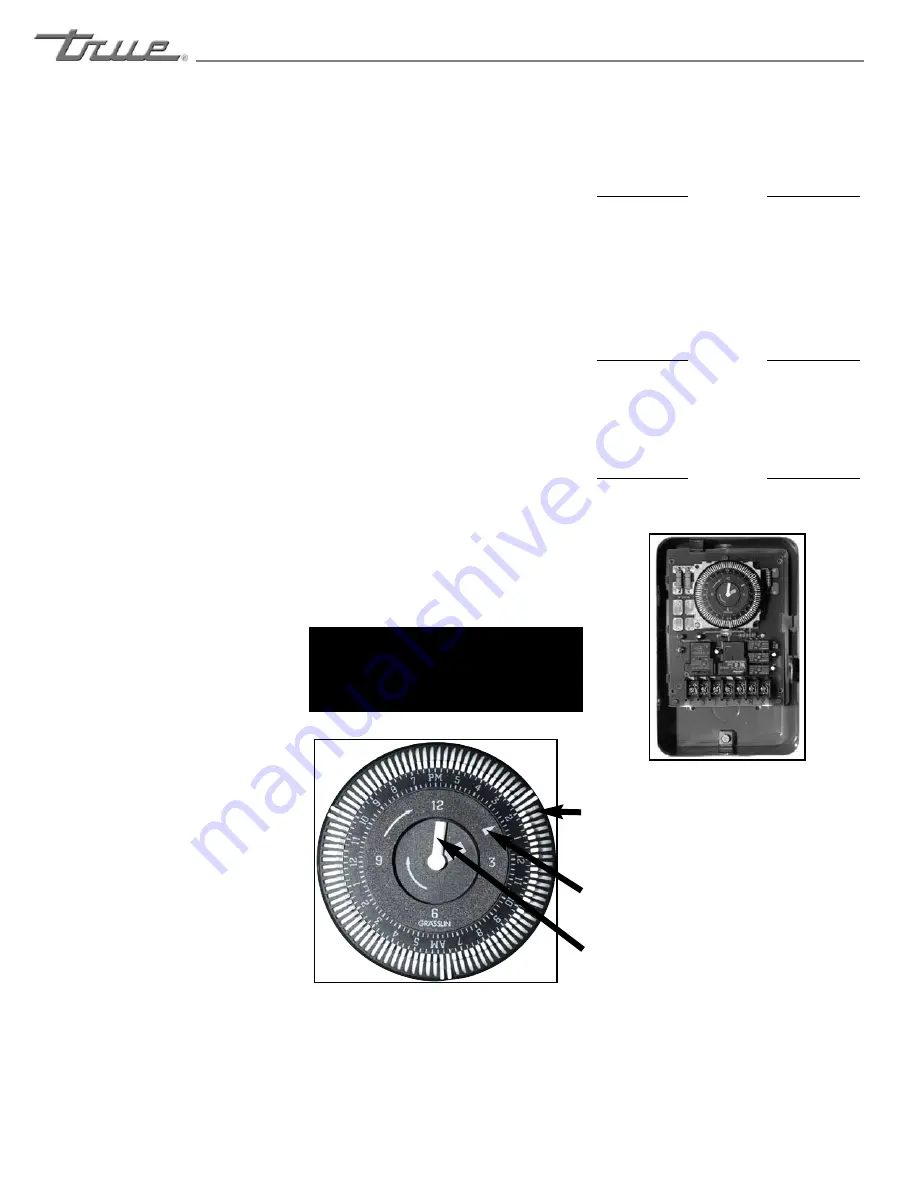

Locating The Defrost Timer:

Take off louvered grill assembly by

removing four (4) corner screws.

TSID and TDBD Models:

Defrost timer is located in the lower

right corner behind the louvered grill

(inside galvanized electrical box).

Setting the timer:

(UNPLUG UNIT FROM

POWER SUPPLY!)

DO NOT SET THE TIME BY ROTAT-

ING THE “OUTER” DIAL.

Turn the minute hand clockwise until

the time of day on the outer dial is

aligned with the triangle marker on the

inner dial (two o’clock position).

Adjusting The Defrost Timer:

(time initiated, time terminated)

Your True equipment contains a defrost

system that is time initiated and time

terminated. While True requires a mini-

mum 3 defrost periods not to exceed 60

minutes the procedure on this page

should be followed to customize your

specific needs.

Notice:

If timer is not set for a minimum of 3

defrost per day for 60 minutes each,

the coil may develop excessive frost.

This may lead to system failure and

product loss, which is not covered

under warranty.

The following procedure may be fol-

lowed to customize your needs.

High usage, high temperature, and

high humidity may require 4 defrost

settings per day.

WARNING:

Always follow the manufacturer’s

recommended settings when

programming the amount and duration

of the defrost cycles.

STEP 1

The white tabs located on the outmost

area of the time clock have been facto-

ry set for (6:00 a.m., 2:00 p.m., and

10:00 p.m.). Each tab represents 15

minutes of defrost time. Notice that at

each defrost time four white tabs are

set for 15 minutes each for a total of 60

minutes of defrost.

STEP 2

In order to program the time to begin

the defrost cycle, flip the white tabs out

to set the defrost time. To eliminate a

defrost time flip the white tabs back

toward the center of the Defrost Timer.

STEP 3

True recommends a 60 minute defrost

cycle three times per day.

Inner most dial.

Time of day.

Outer most dial. White tabs represent 15

minutes of defrost time.

Defrost Timer Box Image 1

Defrost Timer Image 2