Zahn Cup

sec (#2)

Zahn Cup

sec (#4)

Ford cup

sec (#3)

Ford cup

sec (#4)

Poise P

Centi-poise

cP

Krebs

KU

Saybolt

SSU

16

5

0.1

10

60

17

8

15

80

18

12

10

0.2

20

100

19

15

12

25

130

20

19

15

0.3

30

150

22

25

17

0.4

40

210

24

29

19

0.5

50

30

250

27

33

21

0.6

60

33

320

30

36

23

0.7

70

35

370

34

41

26

0.8

80

37

430

37

45

29

0.9

90

38

480

41

10

50

31

1

100

40

530

49

11

58

36

1.2

120

43

580

53

13

66

41

1.4

140

46

690

56

14

67

45

1.6

160

48

790

74

16

51

1.8

180

50

900

Connect the appropriate air hose to the spray gun. Begin turning the material flow screw (#19, page 33) anti or counter

clockwise 1 – 2 full turns. Look at the size of the fluid pattern and flow volume. Adjust before applying material to your

substrate. If you have too much fluid flow turn the material flow screw clockwise. If you do not have enough fluid flow, adjust

the material flow screw anti/counter clockwise. Hold spray gun 4” – 8” (10cm-20cm) from your work surface depending on

the size of your substrate. Closer is generally preferred for highest efficiency and the least amount of overspray. Follow the

proper spray technique as outlined in the spray technique diagram. You can increase or decrease the fluid flow as desired

as well as the distance from your work surface as necessary. Adjust the Fan Pattern Control Ring as desired.

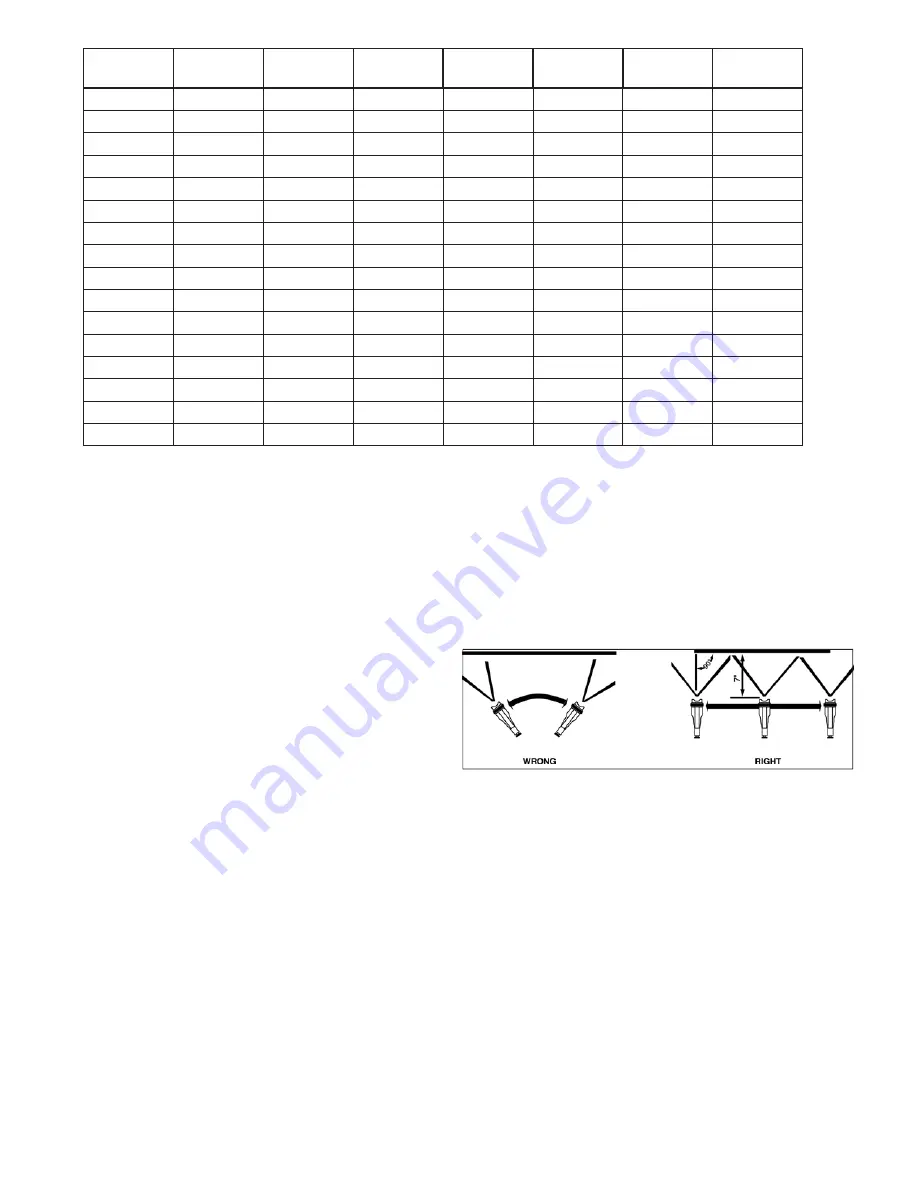

4.2 Spray Gun Technique

Like any skill, practice makes perfect. Never try to rush the

spray finishing process. Learn the characteristics of the

coating you will be spraying. Build up layers of material (3—4

applications or more if necessary). Sand between coats and

allow proper drying time between applications. It is important

to remember to always keep the distance of the spray gun

the same when moving across your work (or up and down).

(Called a “pass”). Do not rotate or turn your wrist from side to side. Move the spray gun across your work from end to end.

Be sure to maintain the same speed of movement. This will ensure an even application of coating. Always release the trigger

at the end of a “pass”. Continue spraying in the opposite direction overlapping your previous coat by 1/3rd to 1/2. When

finished you should have an even wet coat on your work. If you have dry spots you have overlapped too wide. If you have

heavy or wet spots, or runs you have overlapped too much. When spraying a large or preassembled piece, start at the top

and work down. Try to spray the hard to reach and underneath surfaces first. Common sense and some forethought will

prevent errors.

Remember, that a light wet film will generally produce better results than a heavy wet coat. When spraying a vertical surface

it is advisable to spray a thin/light “tack” coat first, followed by a normal light wet coat. This technique will help prevent “runs”

and “sags”. When using your APOLLO spray gun you control five variables:

1. Fluid Flow

2. Distance of the spray gun from your substrate (4”-8” avg., closer if necessary).

3. Pattern Direction (Vertical, Horizontal & Round fan)

4. Speed of application

5. Fan Pattern Size (adjust fan control ring)

Items 1, 2 & 4 directly relate to each other.

Summary of Contents for Apollo 7500 AtomiZer

Page 32: ...8 Diagram Parts List...