7. Troubleshooting

1. Your paint cup is full of material, the HVLP air is supplied to the spray gun, trigger is pulled and no paint comes out—

Reason: Cup not pressurizing.

A. Check Non-return valve installed correctly. (Black half facing toward cup)

B. Check Non-return valve. Clean or replace as necessary.

C. Check Air feed connector has a blockage. Check and clean as necessary.

D. Check to make sure the cup is clamped tight.

E. Check the cup top gasket to make sure that the gasket is not damaged or worn and that the cup is sealing

correctly on it. Replace if necessary.

F. Gravity cup: check air pressure feed line is properly connected and not crimped.

G. Gravity cup: check the cup top gasket to make sure that the gasket is not damaged or worn and that the cup is

sealing correctly on it. Replace if necessary.

2. If you think that you are getting too much “overspray” Try:

A. Moving the spray gun closer to the work (Turbine or compressor).

B. Reduce the fluid flow (Turbine or compressor)

C. Considering using a smaller nozzle and needle assembly (Turbine or compressor)

D. Reduce air pressure (Compressor or Precision series turbines)

3. If the sprayed surface is not flat and level after drying (orange peel effect) Try:

A. Increasing air pressure (Compressor or Turbine Models 835VR, 1050VR, 1100 & 1200)

B. Thin the coating more. (Turbine or compressor)

4. If the finish looks like “dry mist” or if you think the speed of the application is too slow. Try:

A. Increasing the fluid flow

B. Moving the spray gun slower

C. Moving the spray gun closer to the work piece

D. Thin the coating more.

5. Fan Pattern Control Ring is hard to rotate or will not turn. Try:

A. Loosening the fluid nozzle slightly. (Caution – Do not loosen to much or leakage will occur)

B. Locate and slightly loosen air cap assembly screw (#5).

6. When rotating Fan Pattern Control Ring you only get a round spray pattern.

Try: Locate part (#7) Air Distributor Plate which is attached to part (#8) Air Distributor Ring. The position of the air

distributor plate is critical to the operation of the Fan Pattern Control Ring. (See page 29 for correct and incorrect

position). Adjust if necessary.

7. When using a gravity cup fluid delivery is slow or fan pattern size too small.

Best performance with the gravity cup requires cup pressure.

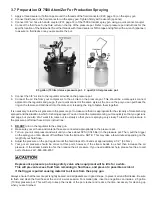

Be sure that the air feed tube is attached from the Air Feed Connector (#22, page 33) to the brass nipple at the top

of the gravity cup.

If you have any additional questions please refer to our website located at www.hvlp.com or call our technical service line

at 888-900-4857.

Summary of Contents for Apollo 7500 AtomiZer

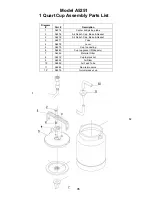

Page 32: ...8 Diagram Parts List...