13

Hose clips SC (part no. 40712-01) are suitable for fastening the pipes

(hoses) to walls or the floor. These hose clips also make it possible to

route water pipes (hoses) on the heater‘s warm

-air distribution pipes

as a way to avoid the danger of frosting.

A water pipe (hose) may only be fitted at a clearance of 1.5 m to the

heater on the warm air duct. The Truma hose clip SC can be used if

this distance is observed. In the case of parallel installations, e.g.

openings through a wall, a spacer element should also be attached

(e.g. insulation) to prevent contact.

Connect cold water supply (23) to safety/drain valve (24). To

guarantee the correct function of the safety/drain valve, the water

pipes/hoses need to be installed without tension!

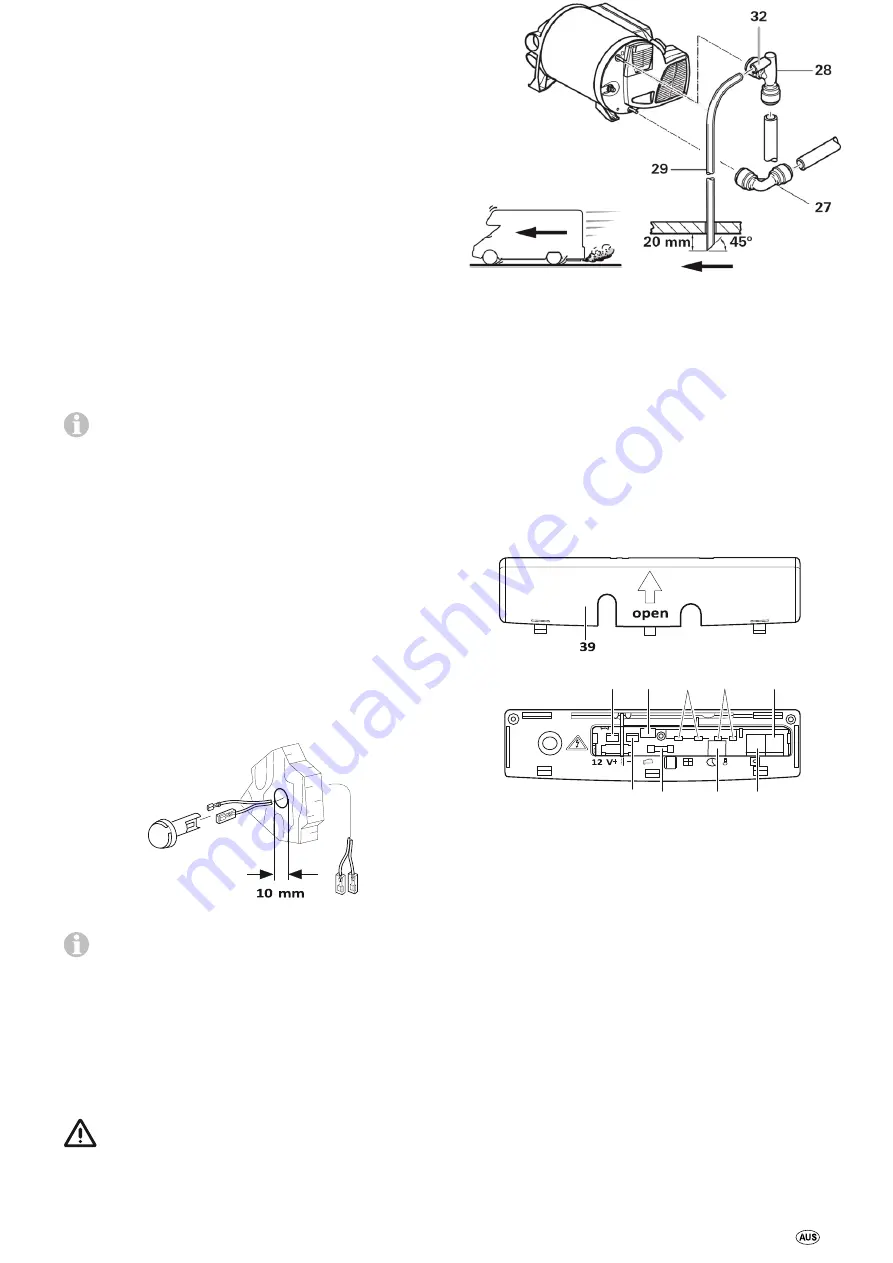

Fig. 25

The elbow fitting (28

–

with aeration valve) is inserted into the upper

warm water connection and the second elbow fitting (27) is inserted

in the lower cold water connection of the heater up to the stop. Pull

in opposite direction in order to make sure the elbow fittings are

securely attached.

Create a pipe/hose connection (25) for the cold water supply

between the safety/drain valve (24) and the boiler intake.

Ensure that the cold water supply does not come into contact

with cold bridges (e.g. the outer wall) in order to

prevent freezing.

Route the hot water supply (26) from the elbow connec tion with

integrated vent valve (28) to the hot water consumers.

Push the venting hose, external diameter 11 mm (29), onto the hose

grommet of the venting valve (28a), and lay it to the outside without

any kinks. Ensure that the bend radius is not smaller than 40 mm.

Cut off the aeration hose about 20 mm below the vehicle floor at a

45° angle to the direction of travel (see figure 25).

Installing the room temperature sensor

When selecting the location, bear in mind that the room

temperature sensor must not be subjected to any direct radiant

heat. For optimum room temperature regulation, we recommend

that the room temperature sensor be fitted above the entrance

door.

Fig. 26

Please ensure that the room temperature sensor is always

attached to a

vertical

wall. There may be no ob-

structions preventing the room air from flowing around it.

Drill a hole 10 mm in diameter. Guide the connection cable through

the drillhole from behind and plug the cable end to the sensor by

means of an insulated connector plug (there is no need to be

concerned about polarity). Slide in the room temperature sensor

and lay the cable end with the two insulated connector plugs to the

electronic control unit (extend to a maximum overall length of 10

m using 2 x 0.5 mm² cable if necessary). connected, otherwise the

heater will switch to fault.

The provided room temperature sensor

must always be

Installing the control panel

The installation of the control panel is described in the instructions

included with the control panel.

Electrical connections

Route connecting cables in such a way that they cannot chafe.

Please also use leadthrough bushings or edge protection profiles

where there are sharp edges such as metal panel leadthroughs. The

connecting cables must not be attached to or come into contact

with metal surfaces, the exhaust duct or warm air ducts.

The electrical connections are located under the connection cover

(39). The cover can be removed by pressing and simultaneously

sliding it in the direction of the arrow. When removing or

installing the connection cover on the connection cables, make

sure that the cables are not pulled out or become pinched.

40

42

44

46

48

41

43

45

47

Fig. 27

40 = Input v12 V (spade connector 6.3 mm) 41 =

Input voltage -12 V (spade connector 6.3 mm)

42

= not used

43

= Device fuse: 10 A

–

slow

–

(T 10 A)

44

= Wire bridge (or window switch

–

accessory)

45

= not used

46

= Room temperature sensor

47

= Control panel / Diagnostic connector*

48

= Control panel / Diagnostic connector*

* Alternative connections.

All connections to the unit should be made with sagging connection

cables. This will prevent condensation water from running down the

connection cables and into the unit.