18

Remote control battery change

Please only use leak-proof micro-batteries with a steel outer

casing, type LR 03, AAA, AM 4, MN 2400 (1.5 V).

When inserting new batteries, take care not to reverse the

positive and negative terminals!

Figure 3

Empty, used batteries can leak and damage the remote

control! Remove the batteries if the remote control is not

being used for a long period of time.

No warranty is given for damage caused by leaking

batteries.

Disposal

Neither the remote control nor the batteries may be

disposed of with domestic refuse, instead they must be

sent for recycling separately via a collection point. By

doing this you are contributing towards reuse and recycling.

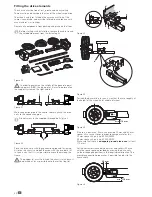

Manoeuvring the caravan

Follow the “Safety instructions” before using the Mover!

With the caravan uncoupled (apply parking brake and secure

against rolling away) engage the drive rollers on the tyres us-

ing the lever provided. Turn the lever until it cannot be turned

any further without excessive force. In the end position the

drive unit engages securely. This must be checked on both

sides before manoeuvring.

Before starting the Mover, release the parking brake

and remove the chocks.

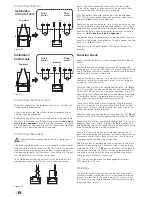

Move the slide switch (a) on the remote control to the “On”

position – the green LED flashes in combination with the

audio signal for approx. 5 seconds until the control unit is

ready for use.

Movement in all directions is possible using the control knob

and the slide control.

The Softstart / Softstop makes the caravan start to move

without jolting, and brakes it gently when stopping.

When the control knob or slide control are released, or if the

radio signal is interrupted or becomes too weak, the caravan

stops moving. Radio equipment and other Moverremote con-

trols will not activate your Mover.

After start-up, the Mover moves at a steady speed (according

to the setting on the slide control). Speed increases slightly on

downhill slopes and decreases on uphill slopes.

System factors mean that the speed increases on slopes.

To reduce the speed, it is necessary to stop often (slide con-

trol in the idle position) and then start again.

Move the slide switch on the remote control to the “Off” pos-

ition

to switch off the remote control and the Mover.

The slide switch also acts as an “Emergency Stop”

switch.

After manoeuvring,

apply the parking brake first

and se-

cure the caravan with chocks to prevent it from rolling away,

then

disengage the drive rollers from the tyres.

Coupling to a towing vehicle

The Mover allows a caravan to be coupled to a towing vehicle

with millimetric precision. However, this requires care and a

degree of practice.

Following the operating instructions, move the caravan close

to the towing vehicle (apply parking brake and engage gear).

In order to position the caravan precisely, operate the control

knob or slide control until the caravan’s coupling is located

precisely over the ball coupling on the towing vehicle. Then

couple the caravan to the vehicle by lowering it at the support

wheel in the usual manner.

Prepare the caravan for towing in the usual way.

The caravan must not be towed with the drive

rollers engaged.

Maintenance

Keep drive elements clear of coarse road dirt. When cleaning

the caravan, spray the Mover with a water hose to remove

mud etc. Make sure that no stones, twigs etc. are trapped in

it. The control unit does not require servicing. The remote con-

trol must be kept in a dry place.

Clean the Mover as described above every year (or before

overwintering).

Do not park the caravan with the drive rollers engaged.

To prevent the battery from becoming totally discharged dur-

ing long periods of inactivity, it must be disconnected and

then recharged from time to time. Charge the caravan battery

before starting up.

It is extremely easy for you or your caravan dealer to perform

the checking and maintenance of your Mover during the an-

nual inspection of your caravan. If in doubt, please contact

Truma Service (www.truma.com).

Checks

– Check the installation, wiring and connections for damage

at regular intervals. The drive units must be able to move

freely, and the spring must automatically return them to

the safe idle position when they are disengaged. If this is

not the case, check the drive units for dirt or corrosion on

their guides, and if necessary have them cleaned by trained

specialists.

– After the annual inspection, check whether all motors react

properly to the commands from the remote control.

– At least every 2 years, an

expert

must check the Mover for

rust, check that detachable parts are firmly attached and

check that all safety-related parts are in good working order.