25

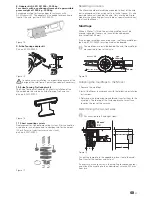

Move the drive units in a lateral direction in such a way that

as much of the tread area of the tyre as possible is covered.

Ensure that there is an adequate distance between the gear-

box and the tyres / shock absorbers so that they do not come

into contact.

The minimum distance with the drive rollers engaged is

10 mm.

min.

10 mm

Figure 27

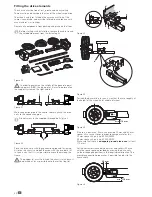

Once the drive units have been correctly positioned, tighten

the bolts (c) of the fastening kit a little, then check the re-

quired distances again. The weight of the caravan must be

resting on the wheels when doing this.

Place the movable connection pipe in the centre (use the

marking) and fix each side with 1 threaded bolt (g) M8 x 12

(15 Nm).

The threaded bolts are coated with sealant, and must

therefore only be bolted in once.

Re-check the distance of 20 mm from the tyre (with the

wheels under load). Then tighten the 2 bolts of the fastening

kit (M10) several times in turn with a torque of 25 Nm.

25 Nm

Figure 28

The bolts are coated with sealant, and must therefore

only be bolted in once.

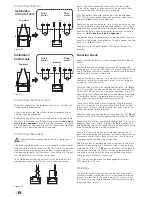

Fitting the cross actuation device

Make sure that the drive rollers are

not

engaged on the tyres

(on both sides).

Push the connection pipes (1) into the central pipe (2) with the

holes facing outwards.

Push the connection pipes (1) onto the toggle crank (a). Insert

the bolts (5) through the toggle crank and tighten with the

nuts (4) (10 Nm ± 1 Nm).

Centre the central pipe (2), measuring again if necessary. In

this position, tighten the 2 threaded bolts (3) (15 Nm). Finally,

check all the bolted connections again.

4

2

3

1

a

5

5

3

4

5

1

M

ov

er ®

SX

M

ov

er ®

SX

Figure 29

Engage the rollers using the lever provided. The drive rollers

should now be engaged on both sides. Check the opposite

side as well. Disengage the drive rollers again.

Repeat this procedure on the opposite side.

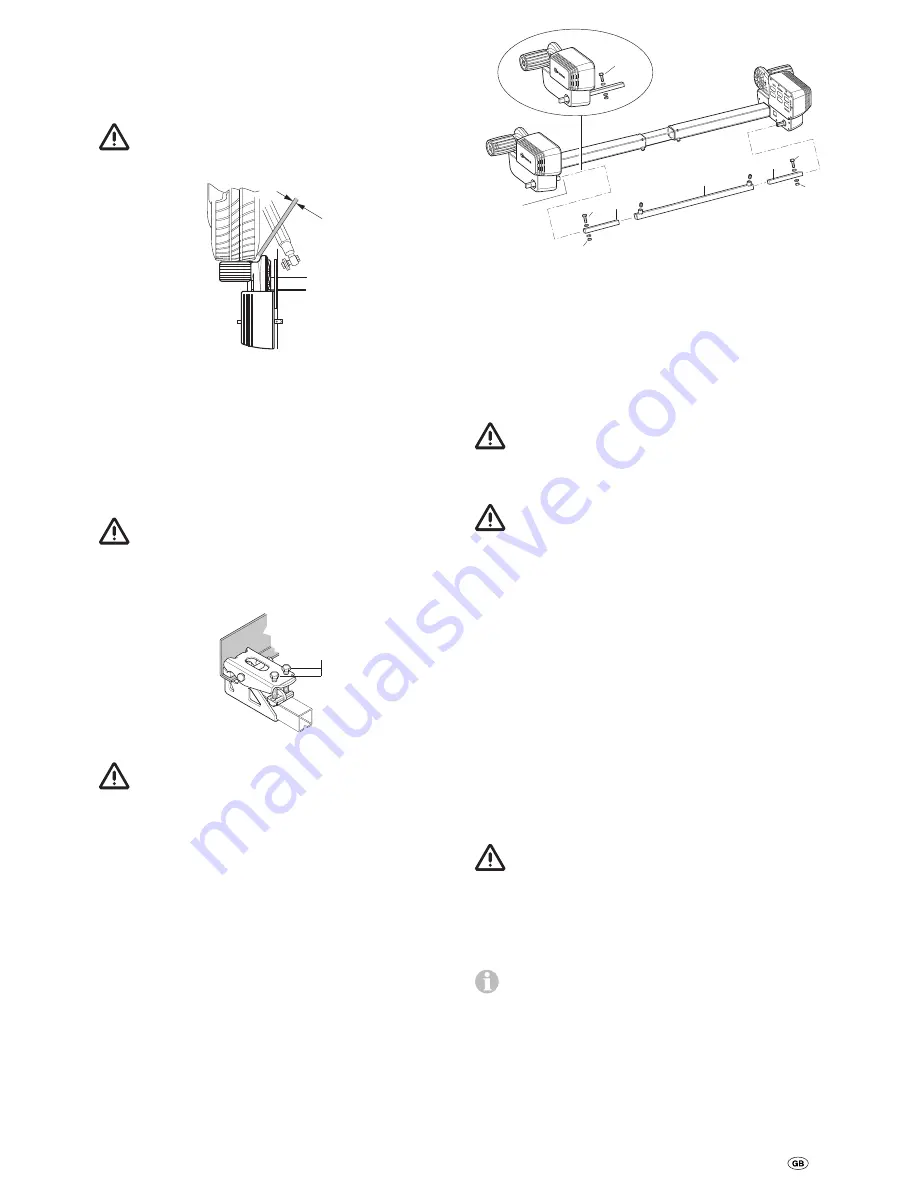

Electrical wiring and control unit

It is recommended that installation and connection be

performed by trained specialists.

The Mover is only suitable for connection to 12 V batteries

(DC voltage).

Before commencing work, disconnect the battery and

any external electrical power supplies.

The electrical installation must comply with the technical

and administrative regulations of the respective country of

use (e.g. EN 1648-1). National regulations and rules must be

followed.

Two high-power cables are factory-fitted to each drive unit for

the drive motor (6 mm²). Mark the relevant motor connect-

ing cables (motor A or B – see also connecting diagram) and

temporarily route them along the caravan floor to the location

where it is planned to install the control unit. An example of a

suitable location for the control unit is in a bed stowage box in

close proximity to the manoeuvring assistant

at least 40 cm

away from the battery, and it must not have a metallic

housing.

Place the control unit in the stowage box and secure with the

chipboard screws provided (5 x 16).

At a distance of approx. 150 mm from the control unit con-

nection strip, mark a hole with a diameter of 25 mm on the

floor of the caravan through which to pass the wiring looms.

Before drilling, check for underlying frame sections,

tanks, gas lines, water pipes and electrical cables.

Drill the hole and pass the cables through the floor of the

caravan to the control unit, routing them in such a way that

they cannot chafe (especially where they pass through metal

panels). Use the protection pipes provided to prevent damage

to cables.

The drive motors move during engagement and

disengagement.

In order to compensate for this, se-

cure the

cables

in this area

loosely

with a little play to pre-

vent the cables from being stretched.

No

cable must be laid

over the control unit.

Secure the cables to the chassis or underbody using the clips

and screws provided.

Seal the hole in the caravan floor with plastic body sealant.