26

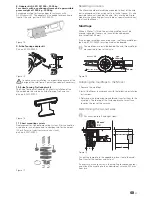

Connecting diagram

+ –

+ –

– +

1

2

3

4

Top view

A

B

A

B

Installation

in front of axle

+

-

Drive

motor

Drive

motor

Figure 30

– +

– +

– +

1

2

3

4

B

A

Battery

Installation

behind axle

+

-

A

B

Drive

motor

Drive

motor

Top view

Figure 31

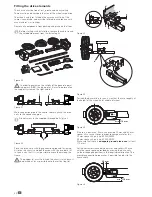

Connecting the drive motors

The motor cables must be routed in such a way that they can-

not be torn off or damaged.

Surplus cable must be laid without loops in serpentine lines

and must not be shortened.

Release the flap of the control unit connection strip and clamp

the cable in accordance with connecting diagram

(red = posi-

tive, black = negative).

Push the spade connectors fully onto

the plug contacts. Please ensure that the connections are made

properly. Press down the flap until it engages.

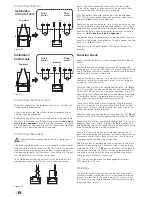

Connecting the battery

Incorrect battery connection results in a control unit

fault.

Liquid electrolyte batteries must be installed in a separate box

with ventilation leading to the outside. The fuse in the positive

lead must be connected outside the box. A separate box is

not required for gel or AGM batteries. Pay attention to the bat-

tery manufacturer’s installation instructions.

The outgoing lines from the terminals must be routed with a

gap between them until after the fuse in the positive lead.

+

-

+

-

Figure 32

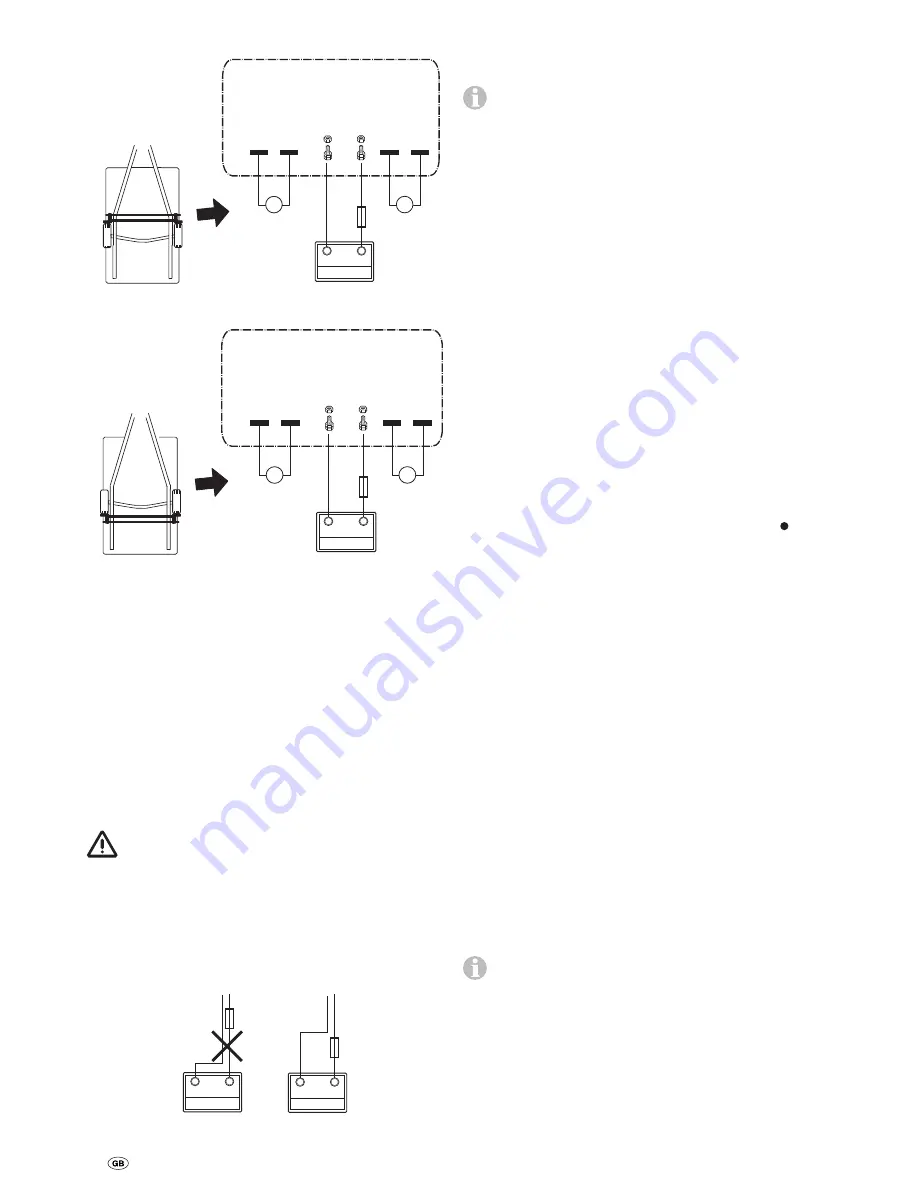

Route the battery connector cables (only use the original

Truma cables supplied) to the control unit and attach them

securely using the clips and screws provided.

The battery connector cables must not be extended.

They must be routed separately from the motor cables,

and must

not

run over the control unit.

Route battery connector cables so that they do not chafe (par-

ticularly at lead-throughs through metal panels). Use suitable

protective lead-through bushing to prevent damage to cables.

Connect the battery connector cables to the existing battery

terminals

(red = positive, black = negative).

The connection to the control unit (as per the connecting dia-

gram) must be made in the order: nut, battery connection ring

eyelet, nut (torque 7 Nm ± 1).

Connect fuse in the positive lead (150 A) near the positive

terminal.

Function check

Check whether the battery is fully charged for operating the

Mover.

Position the caravan on open, level ground and apply the

parking brake, or secure with chocks to prevent it from rolling

away. The drive rollers must not be in contact with the wheels

and the corner jacks must be raised.

Connect the battery terminals to the battery. Check that all

cables are securely attached and not hot, and that there are

no signs of short circuits etc.

Move the slide switch on the remote control to the “On” pos-

ition. This switches on the remote control, and the green LED

flashes until the control unit is ready for operation. If the LED

does not light up, check the polarity and condition of batteries

in the remote control. The remote control switches itself off

after about 1 minute if no controls were actuated.

Check that neither drive motor is running. With the remote

control switched on at a distance of no more than 2 m from

the control unit, press the slide control forwards. Both drive

rollers should now rotate forwards.

Move the slide switch on the remote control to the “Off”

pos-

ition to switch off the remote control and therefore the Mover.

Engage the drive rollers using the lever provided. Turn the en-

gagement lever until it locks into position both mechanically

and noticeably and can no longer be turned without excessive

force (the end position is roughly horizontal).

Ensure that there are no obstacles around the caravan, re-

lease the parking brake and remove the chocks and switch on

the remote control. Now check all functions several times in

accordance with the operating instructions.

Apply the caravan’s parking brake and secure with chocks to

prevent it from rolling away. Move the slide switch on the re-

mote control to the “Off”

position to switch off the remote

control and therefore the Mover. Disengage the drive rollers

using the lever and check the distance between the rollers

and tyres again. Readjust if necessary.

The distance between the disengaged drive rollers

and tyres is 20 mm.

Warnings

The installer or vehicle owner must apply the yellow sticker

with the warning information, which is enclosed with the ap-

pliance, in a location in the vehicle where it is clearly visible

to all users (e.g. the wardrobe door). Missing stickers can be

requested from Truma.