E233en1_02.doc

N 1000 - 1

GB

1

Nibbler N1000-1

Fig. 13447

N1000-1 specifications

Max. material thickness:

1

st

gear

2

nd

gear

•

Steel up to 400 N/mm²

10 mm

8 mm

•

Steel up to 600 N/mm²

7 mm

5 mm

•

Steel up to 800 N/mm²

5 mm

4 mm

•

Aluminium 250 N/mm²

12 mm

10 mm

Smallest radius for curve-shaped cutouts

300 mm

Sectional sheets (90°) for 10 mm

sheet thickness: inner bending radius

min. 12 mm

Starting hole

∅

for die

min. 75 mm

Cutting track width

12 mm

Working speed 1st gear

approx. 1.0 m/min

Working speed 2nd gear

approx. 1.6 m/min

Nominal power consumption

2900 W

Number of strokes under max. load, 1st gear

210/min

Number of strokes under max. load, 2nd gear

350/min

Weight

14.7 kg

Operating pressure (flow pressure)

6 bar

Air consumption at 6 bar

3.1 m³/min

Required inner

∅

of compressed air hose

18 mm

(max. output not reached if

∅

is smaller)

Noise / Vibration

Measured values established in acc. with EN 50 144.

The A-weighted noise level of the unit is typically:

sound level 86

dB

(A); acoustic capacity level

94 dB (A).

Wear ear protection!

The hand-arm vibration is typically lower than

2.5 m/s².

Proper use

The

TRUMPF Nibbler N1000-1

is a pneumatic hand

machine

•

part plate-shaped workpieces made of material

such as aluminium, non-ferrous heavy metals,

and plastic

•

cut tubes and work sheets with bent profiles or

bent sheets, e.g. tanks, crash barriers, troughs,

etc.

•

to nibble straight or curved outer edges and

inside cutouts

•

to nibble according to a scribed line or template

Nibbling produces undistorted cutting edges.

GB

1

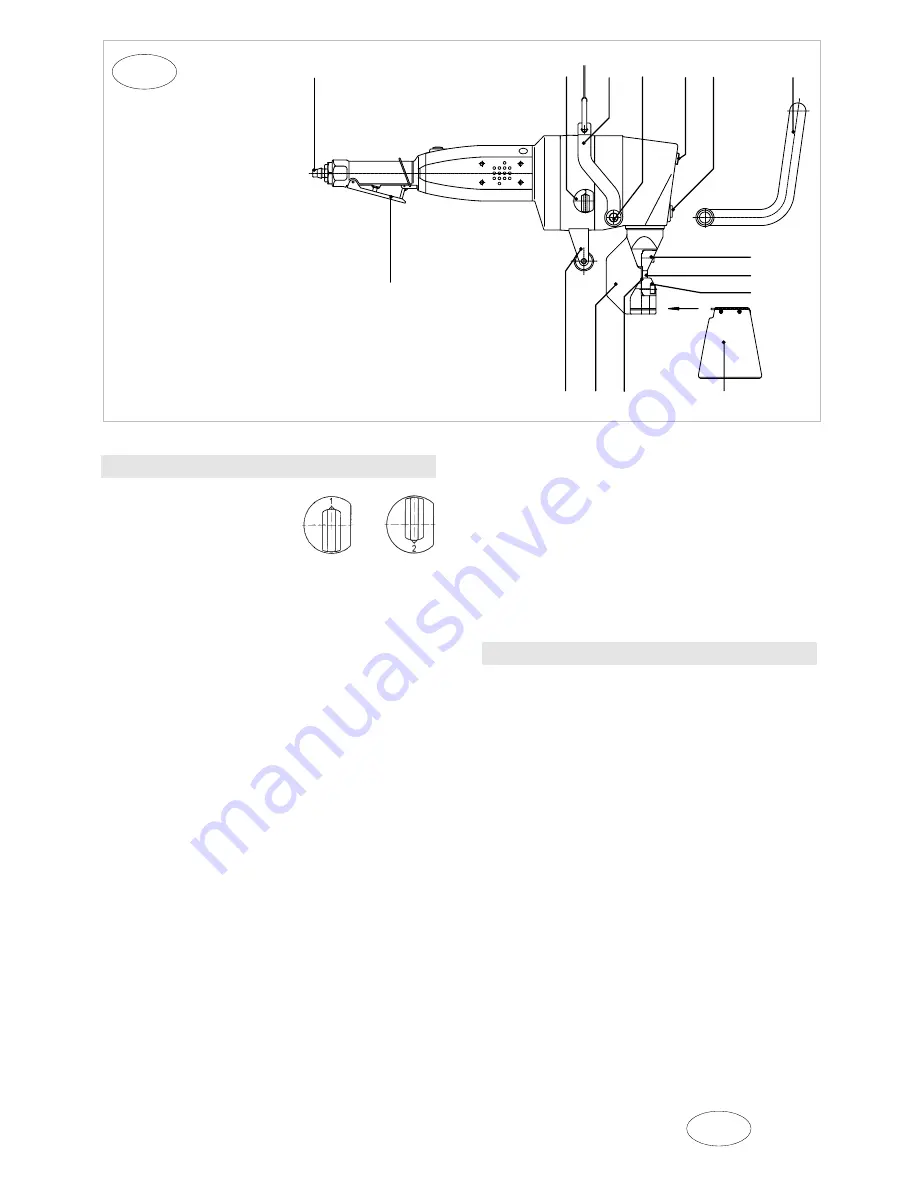

Die

5

Punch guide

6

Wearing plate

7

Die carrier

9

Punch

14

Clamping screw ( = fastening

screw for die carrier)

16

Handle

22

Eccentric shaft

24

Cheesehead screw (2) to

fasten handle or suspension

bracket

40

Gear switch

46

Roller holder

341 Lever and On/off switch

358 Quick-release coupling

A

Suspension bracket (optional)

S

Chip bag (optional)

40

A 24

22 14

16

5

9

1

6

7

46

S

358

341

Summary of Contents for Nibbler N1000-1

Page 1: ...Operator s manual english N 1000 1...

Page 2: ......

Page 12: ...10 GB N 1000 1 E233en1_02 doc...