E233en1_02.doc

N 1000 - 1

GB

7

Resharpening tools

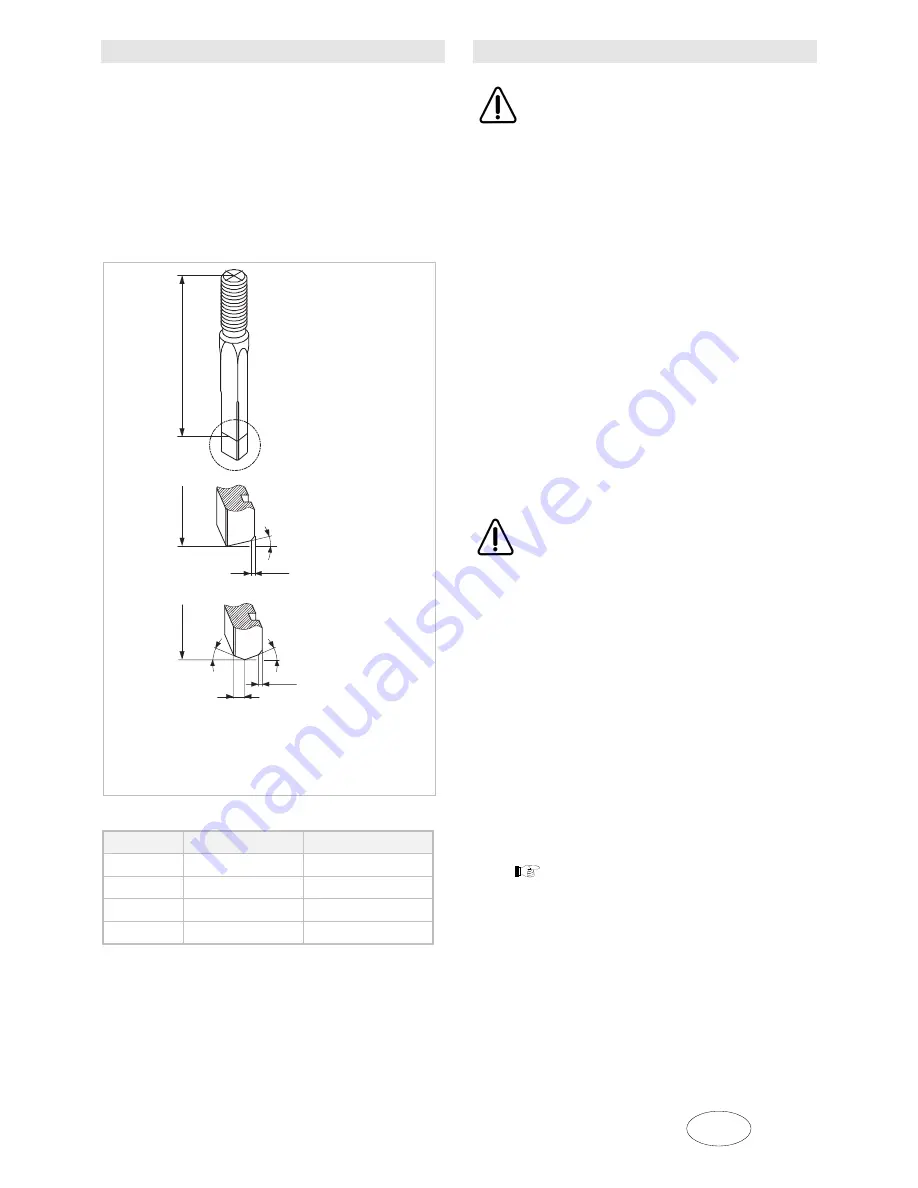

Punch

The punch may be sharpened by approx. 5 to 10 mm

depending on the die used (see table below).

•

Sharpen the face according to the following

illustration and provide proper cooling.

•

Touch up the cutting edge with a fine oil stone.

•

Ensure that the minimum length is maintained.

Punches that are shorter must be replaced (risk of

collision).

Resharpening diagram for punch

Fig. 9017

Die type

Minimum length X

Resharpening reserve

P10

92 mm

5 mm

10

89.5 mm

7.5 mm

7

87 mm

10 mm

5

85 mm

12 mm

Dies

cannot be resharpened.

Maintenance

Danger of injury

Always disconnect the compressed-air

tube from the machine before beginning

any work on the machine!

L u b r i c a t i n g the punch guide/die carrier

Lubricate the punch guide and die carrier after every

tool change.

Original grease: Lubricating grease "S1" (Tube)

TRUMPF Order No. 121486

L u b r i c a t i n g the gears/gearhead

The gear grease must to be replenished or changed

after repairs but no later, however, than after 300

hours of operation.

Original grease: Lubricating grease "G1"

TRUMPF Order No. 139440

Compressed-air motor l u b r i c a t i o n

Damage to property

Lubrication of the compressed-air motor

is very important. The motor will fail if it

is operated without lubrication even for a

short time.

There are two ways to check that the compressed-air

motor is properly lubricated:

1.

For short operating times or varying operating

sites via the

internal oil chamber

.

•

You must ensure that the oil level in the oil

chamber is sufficient before each use.

Lubricating interval: approx. 1 operating hour

•

Oil is refilled through the opening in the sealing

screw, screw-plug (313).

•

Ensure that the oil level is not too high.

See Fig. 10313

2.

It is receommended that an

oil mist

lubricating device

(e.g. Atlas Copco DIM

25) be installed in the compressed-air line for

continuous operation.

1 x 4 5 °

3

10

°

10

°

1 x 4 5 °

8°

X

X

X

'

! " "

Punch (standard)

Order no. 112900

to machine materials up to 400

N/mm² e.g. aluminium, mild

steel

Punch for high-tensile sheets

Order no. 120344

to machine materials over

400 N/mm² e.g. chrome steel

X = minimum length

Summary of Contents for Nibbler N1000-1

Page 1: ...Operator s manual english N 1000 1...

Page 2: ......

Page 12: ...10 GB N 1000 1 E233en1_02 doc...