4.

Battery connection

TruConvert DC series 1000

Battery connection

Fig. 4-8

■

Plus:

M8 threaded bolt.

■

Minus:

M10 threaded bolt.

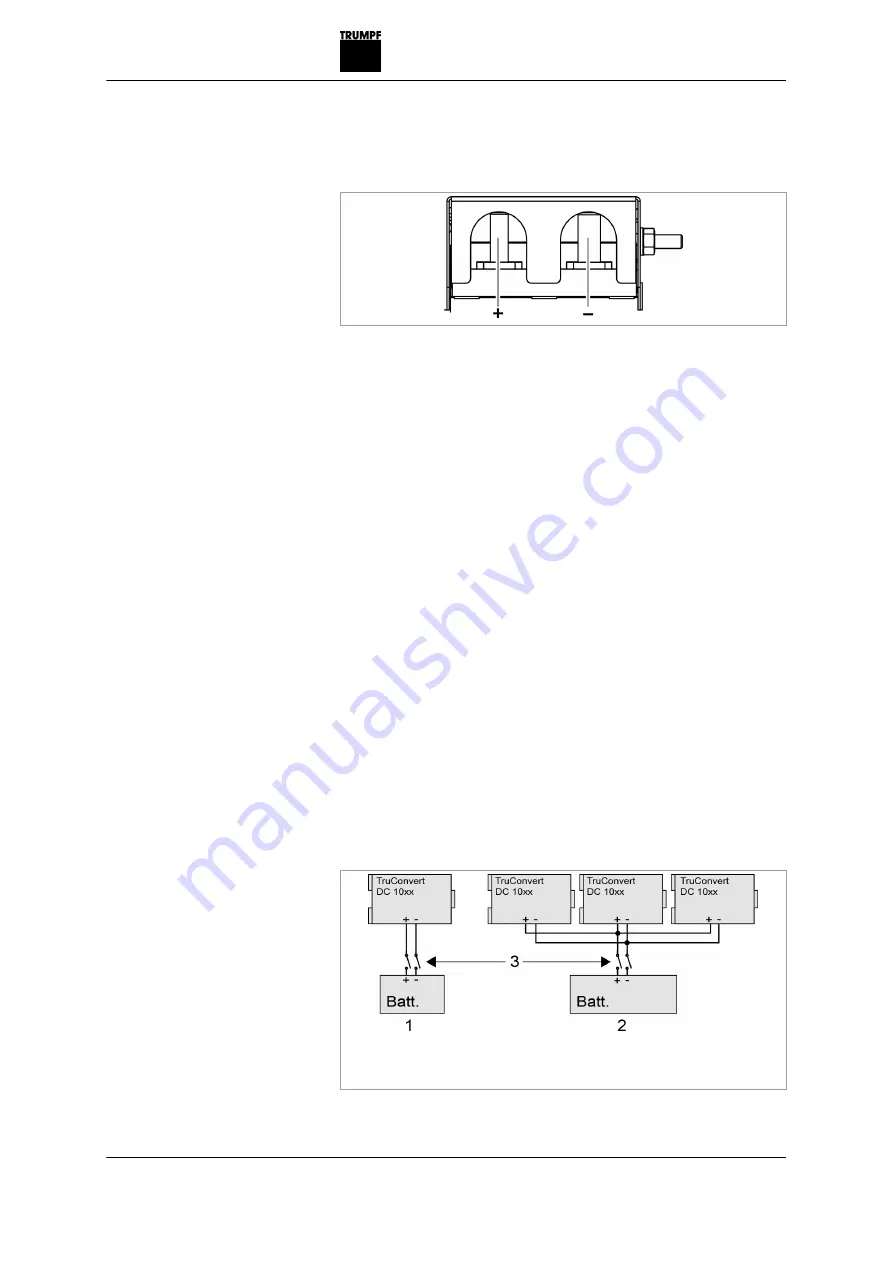

Required connection components:

■

Cable lugs made of ETP copper.

■

Select min. cross section according to local regulations.

■

Max. inductivity: 7.5 µH.

■

Max. length: < 5 m.

Note

To keep inductivity at a minimum cables should be twisted.

All-pole, max. 350 A.

The customer must install suitable separation devices into the

connection between the DC-DC module and battery.

The separation devices must comply with applicable standards.

■

Individual connection.

■

Parallel connection (up to 3 DC-DC modules).

1

Individual connection

2

Parallel connection

3

Separators

Connection types for the batteries

Fig. 4-9

A67-0140-00.BKen-0

01-05

2020-07-01

Battery connection TruConvert DC series 1000

4

‐

7

View

Connection

Cable requirement

External fuse protection

Separators

Connection types

Summary of Contents for TruConvert DC 1000 Series

Page 1: ...Operator s manual TruConvert DC series 1000 TruConvert System Control TruConvert Modular...

Page 2: ......

Page 6: ...II Good to know 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 36: ...3 12 Technical data dependent on device variant overview 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 38: ...7 Ethernet 4 10 8 RS 485 4 11 4 2 Interfaces 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 40: ...Fig 4 3 4 4 Protective earth TruConvert DC series 1000 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 48: ...4 12 RS 485 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 54: ...5 6 CSA certification 2020 07 01 A67 0140 00 BKen 0 01 05...

Page 106: ...16 State diagram State machine Fig 7 19 7 38 State diagram 2020 07 01 A67 0140 00 BKen 0 01 05...