E623EN_01.DOC

Operation

23

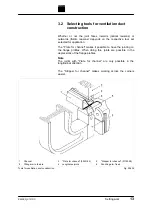

Information concerning the workpiece and

the joint

1 Punching

side

2 Thicker

workpiece

3 Thinner

workpiece

4 Die

side

1. Adjust the set of tools to match the material thickness actually

present.

2. In case of different material thicknesses, the thinner workpiece

has to be on the die side. Joints can be achieved with material

thickness differences of up to ratios of approximately 1:2.

3. The thinner workpiece determines the maximum shear

strength of the component.

–

Work with lubricants when processing aluminum and V2A

(increases service life).

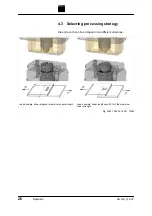

4. The direction of the joint can be rotated by 90° (not possible if

"Plate for channel" (order no. 0243189) is used). For this, the

die is mounted in the desired position and the punch is aligned

accordingly.

Note

The total material thickness measured counts as the

recommended value for selecting the die arm. It is also possible to

connect more than two workpieces with each other. In general, the

more workpieces that are joined together, the less the holding

force of the joint/bond will be.

Fig. 50427