3.

Setting work

3.1

Adjusting the ram length

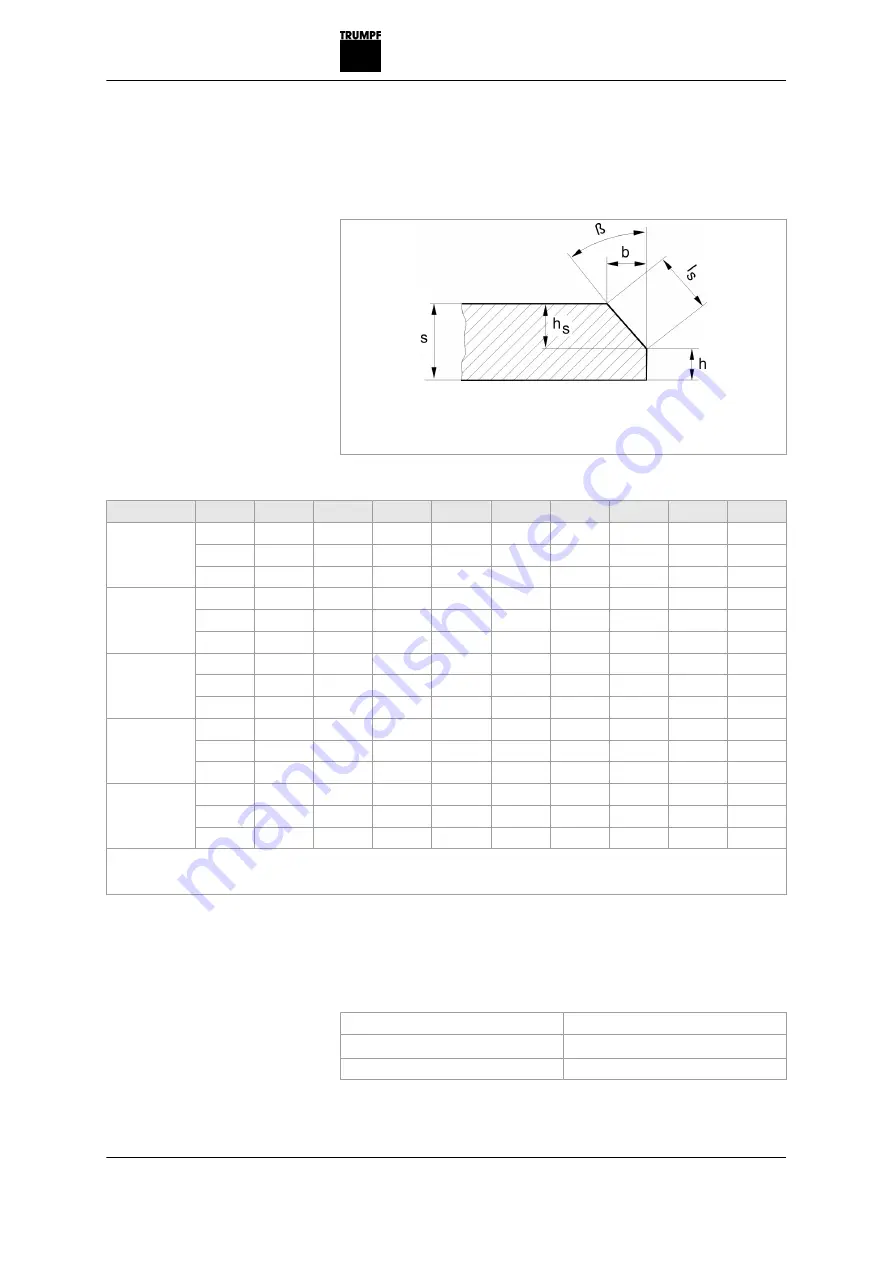

s

Material thickness

β

Angle of bevel

ls

Length of bevel

hs Height of bevel

b

Width of bevel

h

Residual height

Length of bevel and angle of bevel

Fig. 9664

W

8

7

6

5

4

3

2

1

0

mm

ß 55°

14.5

13.3

12.1

10.8

9.7

8.4

7.2

6.0

4.8

ls

11.9

10.9

9.9

8.9

7.9

6.9

5.9

4.9

3.9

b

8.3

7.7

7.0

6.2

5.6

4.8

4.2

3.5

2.8

hs

ß 45°

15

13.6

12.12

10.8

9.4

8

6.5

5.1

3.7

ls

10.6

9.6

8.6

7.6

6.6

5.6

4.6

3.6

2.6

b

10.6

9.6

8.6

7.6

6.6

5.6

4.6

3.6

2.6

hs

ß 37.5°

15.5

13.8

12.2

10.5

8.9

7.3

5.6

4

2.4

ls

9.4

8.4

7.4

6.4

5.4

4.4

3.4

2.4

1.4

b

12.3

11

9.6

8.3

7

5.8

4.4

3.1

1.9

hs

ß 30°

-

15

13

11

9

7

5

3

1

ls

-

7.5

6.5

5.5

4.5

3.5

2.5

1.5

0.5

b

-

13

11.2

9.5

7.8

6

4.3

2.6

0.8

hs

ß 20°

-

-

15

12.2

9.2

6.2

3.3

-

-

Is

-

-

5.1

4.2

3.1

2.1

1.1

-

-

b

-

-

14

11.4

8.6

5.8

3.1

-

-

hs

ß Angle of bevel

W Scale value which must be adjusted on the crank sliding block

Tab. 5

For angles of bevel > 45°, machine using special stripper.

Example for working with the table:

β desired

30°

l

s

13 mm

W (from the table)

6

Tab. 6

10

Setting work

E1026en03

Summary of Contents for TruTool TKF 1500 3A1

Page 2: ......