6

6.3 Grounding

Trunsun Solar modules use an anodic oxidized

aluminum frame to resist corrosion. So the

frame of modules must be connected to the

equipment grounding conductor to prevent

thunder and static injury. The grounding device

must be fully contact with the inside of the

aluminum alloy, and must penetrate the surface

of the frame oxidation film.

Please don’t drill any additional grounding hole

on the frame of the modules.

For optimal performance, Trunsun Solar

recommend the DC cathode of the modules

array is connected to ground. Failure to comply

whit this requirement may reduce the

performance of the system.

The grounding method must not result in direct

contact of dissimilar metals with the aluminum

frame of the modules that will result in galvanic

corrosion. An addendum to UL standard 1703

“Flat Plate Photovoltaic Modules and Panels”

recommends metal combinations not exceed

electrochemical potential difference of 0.6 volts.

The frame rails have pre-drilled holes marked

with is a grounding sing. These holes should

be used for grounding purpose and must not be

used for mounting the modules. The following

grounding methods are available.

There is a grounding hole 4.0mm diameter on

the edge side closer to the middle of the back

frame of module. All module frames should be

grounded for safety. The grounding

connections between modules must be

approved by a qualified electrician, the

grounding itself must be made by a qualified

electrician. The grounding clip accepts solid

uninsulated copper wire sizes 12 AWG. The

wire must not be nicked.

The module shall wire in accordance with the

standard, the grounding method of the frame of

arrays shall comply with IEC 61215. Of course,

in accordance with local laws and regulations to

carry out electrical installation is the best

choice.

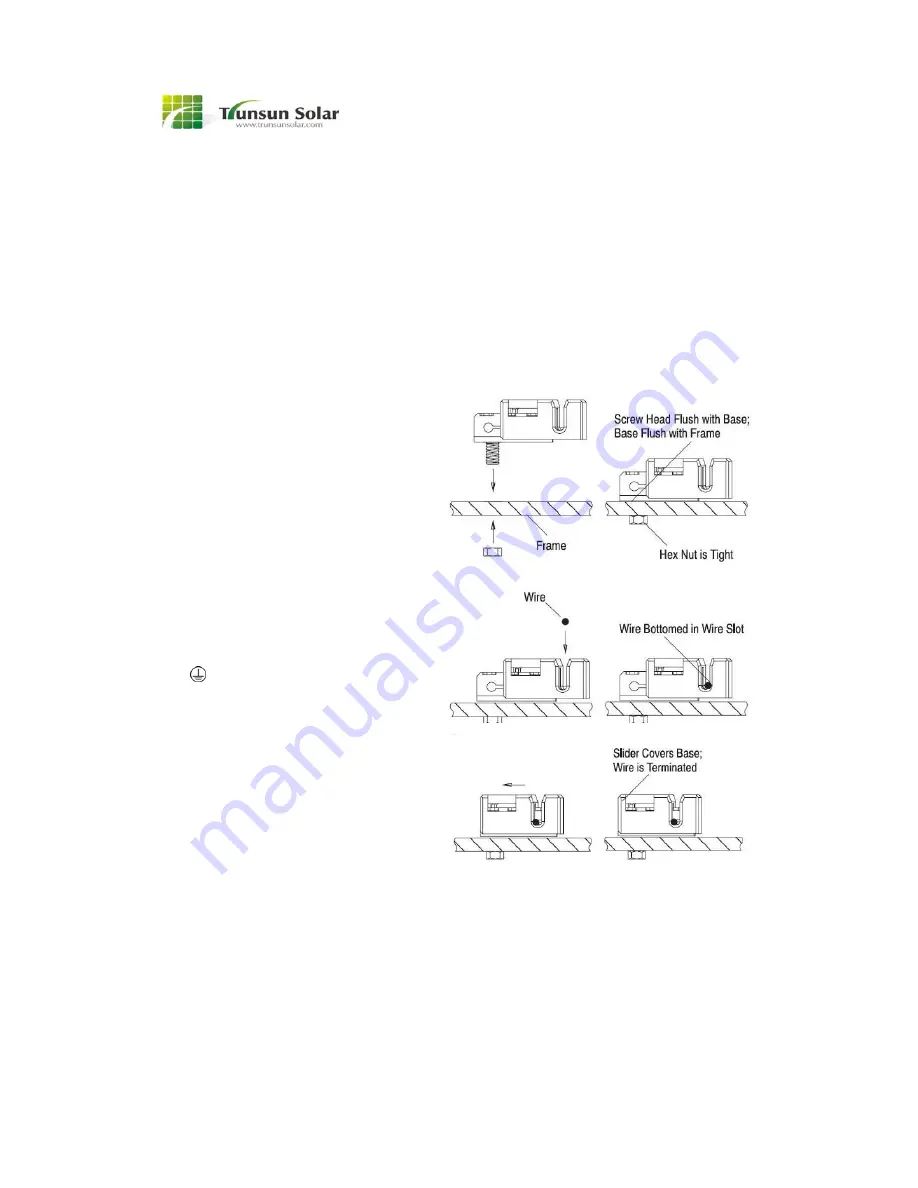

Use the UL listed grounding clip manufactured

by Tyco Electronics Corp with type name

1954381-2. Place the grounding clip onto the

module frame so that the screw straddles the

grounding hole, then tighten the screw and nut

with a torque 2.3 to 2.8 Nm. The head of the

screw must be flush with the base and the base

must be flush with the frame. The copper wire

should not be compressed during the

installation.

Place a 12 AWG copper wire in the wire slot

then engage the slider. Detailed process is as

the following:

Figure 4

Trunsun solar modules can be grounded using

third party grounding devices so long as the are

certified for grounding modules and the devices

are installed according to the manufactures’s

specified instructions.

6.4 Wiring

Modules are equipped with factory installed

wires and quick connectors. Modules have

been designed to be easily interconnected in

series.

Bolt diameter is

4mm.