4

General Safety Warnings

for Pneumatic Tools

Keep your work area clean, tidy and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive areas or in the presence

of flammable liquids or with no ventilation.

Sparks the tool generates could trigger an

explosion or start a fire.

Keep children and passersby at a safe distance while

operating the tool.

Distractions can cause losing control

and cause accidents.

Avoid making contact with power lines and circuits.

Find and avoid power lines and circuits, especially

hidden wiring as well as any grounded object.

Stay alert, use care and common sense.

Familiarity with the tool operation could lead to

distractions while using it. It could cause accidents.

Refrain from using the tool if tired or under the

influence of drugs, alcohol or medication.

Being momentarily distracted while using the

tool could cause severe personal injury.

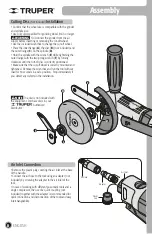

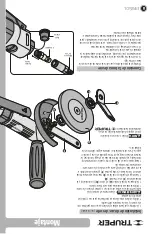

Operate the tool with guards and protection devices in

place and in good working condition.

Failure to comply with this warning is a hazard

of severe personal injury.

Securely fasten and support the work piece.

Use brackets and a stable work surface.

Never force the tool.

Working within the tool’s working design

assures a better and safer job.

Keep the tool in a safe place and out of the reach of

children.

Power tools are dangerous to inexperienced

people.

Wear proper clothes.

Loose clothes, jewelry or long hair could get

caught in the mobile parts.

Keep hands away from rotating and/or mobile parts.

Failure to comply with this warning is a hazard

of severe personal injuries or crushing.

Wear adequate protective safety accessories.

Wear eye protection, dust mask, non-skid safety shoes,

helmet and ear plugs. In normal conditions, the risk of

injury is reduced.

Unplug the air hose from the tool before carrying out

maintenance or replacing accessories.

Prevent accidental startups that cause accidents.

Refrain from operating the tool if the switch is not

working or is not properly assembled.

Failure to complain with this warning is a hazard of

personal injury. Immediately send it to a

Authorized Service Center.

Do not overreach.

Good balance and support lead to better controlling

the tool in unexpected situations.

Never pull the air hose.

Do not use it to carry or unplug the tool from the air

outlet. Damaged or tangled hoses may burst and project

residues towards the operator.

Prevent unintentionally starting the tool.

Double-check the motor is OFF before lubricating,

setting up accessories or carry out maintenance.

Remove brackets before turning on the tool.

Additional tools or vices installed in a rotating

part could cause severe personal injury.

Double-check maintenance and good working

conditions before using the tool.

Carefully check mobile parts, alignment and assembly.

Do it periodically. Look for any damaged element or

parts not working properly. Repair immediately in a

Authorized Service Center.

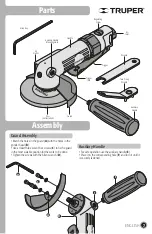

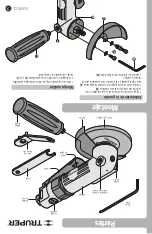

Accessories.

Use only accessories or spare parts indicated in this

Manual or certified by .

Never leave a running tool unattended.

Turn off and disconnect tool after using. Set it in a safe

position to avoid severe injury.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

DANGER

DANGER

DANGER

ENGLISH

Summary of Contents for 101072

Page 10: ...Notes 10 ENGLISH...

Page 15: ...Notas 10 ESPA OL...