5

Risk Control When Using

Pneumatic Tools

• Compressed air out of pneumatic

equipment may be dangerous. Objects like brackets, burrs,

splinters, dust and other residues may be impelled towards

head and eyes due to high speed of the air flow. The air

flow itself can only injure soft tissue such as eyes, ears, etc.

• The tool attachments may get lose or

break and project particles towards the operator or other

operators in the work area.

Risk of injury in head and eyes

• Always, when operating pneumatic equipment wear

protection glasses in compliance with the AMSI Z887.1

Standard. As additional protection, wear a mask.

• Never aim the air flow towards people or animals.

• Disconnect the air hose from the tool when not in use.

• Never set a tool unattended when connected to the air

outlet.

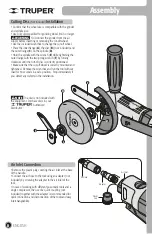

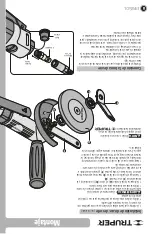

• Before using the tool verify all the parts and accessories

are perfectly secured.

To prevent head and eyes injuries

• Abrasive tools like grinders, sanders

and cutting tools generate dust and particles that damage

the lungs and respiratory system.

• Some materials like resin or adhesive are made with

chemicals and the vapors emitted may cause serious

damage if the operator is exposed for long periods of time.

Risk of inhaling particles

• Always wear a face mask or breathing device when

operating these types of tools.

• Always work in a clean, well ventilated area.

To prevent inhaling particles

• Pneumatic tools do not have electric

insulation. If during the operation, the tool makes contact

with a source of electricity, the energy will be conducted to

the operator causing a fatal electrocution.

Risk of electric shock

• Never use pneumatic tools to work energized electric

wiring.

• Before operating the tool find the possible hidden wiring

in the work zone to prevent making contact.

• Avoid contact with grounded surfaces like pipes,

radiators o refrigerators. The risk of electrocution

increases if the operator’s body gets grounded.

To prevent electric shock

• Incorrect handling of pressure in

pneumatic equipment may cause an explosion causing

severe injuries.

Risk of explosion

• Before using the tool double check the compressed air

source is regulated to the tool specified pressure and

must not exceed 1 380 kPa (200 PSI).

To prevent explosions

• Being exposed long periods of time to

noise pneumatic tools produce may damage hearing

permanently causing hearing loss.

Risk of hearing loss

• Always, when operating pneumatic equipment

wear hearing protection in compliance with the

ANSI S3.19 Standard

To prevent hearing loss

• Pneumatic tools forced beyond the

capacity and lacking of adequate lubrication or used to

loosen rusted nuts (with impact guns) will get damaged

and make the Warranty void.

Risk of damaging the tool

• Keep the tool duly lubricated.

• Do not force the tool.

• Apply “loose it all” liquid to rusted nuts or lugs before

trying to loosen with the tool (impact gun).

To prevent damaging the tool

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

ENGLISH

Summary of Contents for 101072

Page 10: ...Notes 10 ENGLISH...

Page 15: ...Notas 10 ESPA OL...