6

• Damaged hoses may burst and cause

serious injuries or deafness.

•Pneumatic tools connected to the compressed air source,

if operated by untrained staff or underage people, will

cause severe injuries.

• The compressed air used in pneumatic equipment may

be dangerous. Objects like vices, burrs, splinters, dust and

other residues may be impelled by the high-speed air flow

towards the operator or other people in the work area.

• Using inflation nozzles to clean or torch blowing may

cause severe injuries.

• Tools and accessories not suitable, damaged or low

quality like grinding discs, chisels, contacts, drills, brad

nailer, staplers, etc., may shoot out during the operation

and project particles causing severe injuries.

• Brackets may get lose and be projected causing severe

injuries or damage to property.

• Tools that accidentally start may cause severe injuries.

• Tools and accessories with no maintenance may cause

severe injuries.

• Tools using accessories without

certification may cause severe injuries.

• Damaged or banged tools may cause severe injuries.

Risk of injuries

• Do not abuse the hose or the connectors.

• Keep the hose away from sharp or abrasive edges.

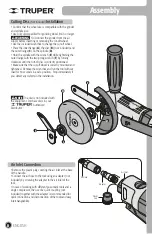

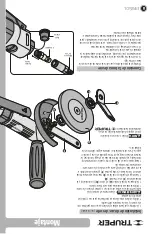

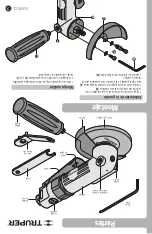

• Unplug the hose when setting up accessories like

grinding discs or bits.

• Never use the hose to carry the tool.

• Never pull the hose to unplug it.

• Do not expose the hose to heat, oil or solvents.

• Before operating the tool, verify the hoses are not

damaged.

• Unplug the air hose when the tool is not in use. Store

the tool in a safe place away from children or untrained

people. Keep children and untrained people away from

the work area.

• Keep the work area clean, tidy and with good lighting.

• Remove any wrench or plier form the tool before

operating.

• Do not use inflation nozzles to clean or to torch

blowing.

• Use only parts, vices and accessories recommended by

.

• Double check all connections are correctly installed.

• Never carry the tool by the trigger.

• Disconnect the air hose out from the tool when not in

use.

• Never leave the tool unattended when connected to the

air outlet.

• Keep the tool handle clean and dry, free of oil or grease.

• Keep tools clean. A meticulously cleaned and oiled tool

delivers a more effective performance and is easier to

control.

• Any type of repair can only be carried out in a

Authorized Service Center.

• Use always accessories matching the tool speed.

• Use only certified accessories.

• Do not use damaged or banged tools.

To prevent injuries

WARNING

Risk Control When Using

Pneumatic Tools

ENGLISH

Summary of Contents for 101072

Page 10: ...Notes 10 ENGLISH...

Page 15: ...Notas 10 ESPA OL...