Turning ON

• Turn on the air compressor and allow it to fill.

• Regulate the air compressor output pressure from 517 kPa

to 758 kPa (75 PSI to 110 PSI).

The tool operates at this pressure range;

operating at higher pressure ranges will result in shorter tool

life.

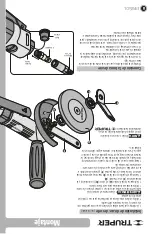

• Slide the trigger lock to the front and then with a full palm

press the trigger to start the grinder spinning.

• Release the trigger to stop the grinder.

• Check that the workpiece is properly clamped. It should be

held in such a way that throughout the cut, the groove made

by the blade maintains or increases its width.

• Squeeze the trigger (

E

) and wait for the tool to reach full

speed before contacting the workpiece. When finished

cutting, remove the tool from the workpiece before turning it

off.

• Do not exert additional pressure on the tool. This decrease

cutting speed and efficiency and overloads the machine.

• In case the blade gets stuck in the cutting groove,

release the trigger and remove the blade from the site.

Check that the blade is properly installed and

undamaged before continuing the operation.

• Confirm that the sparks produced

by the cuts do not become a hazard.

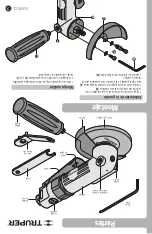

• Using a screwdriver, turn the regulating screw (

F

) to

control the air flow into the tool to adjust the disc

speed.

9

Start Up

Maintenance

E

F

Operation

CAUTION

WARNING

• Pneumatic tools need constant lubrication along their

useful life and during the operation. The compressed air

needed in the tool to run carry humidity which could

oxidize the motor and bearing in the tool. To prevent this

possibility, it is necessary to constantly deliver lubricating

oil through a Brand

UNI-LL-1/4

centralized filter-oiler system installed between the air

compressor and the tool.

• Any excess of oil in the motor is

immediately expelled through the exceeding oil escape.

Keep the escape free of obstructions and never point it

towards people or objects.

• If not using the tool for long periods of time, it shall need

to be lubricated with care.

• After 60 hours’ operation, the tool mechanism need a

little greasing. Excessive grease may diminish power.

• Servicing the tool shall be carried out every 3 months

only in a Authorized Service Center.

Service and maintenance carried out by not certified

people mat y be dangerous and can cause severe

personal injuries as well as making the product Warranty

void.

• Malfunction in the tool caused by no using the

recommended dose of lubrication, or not complying

with this Instructions, or repairs carried out by people

not certified by will not be covered

with the Warranty. We reserve the right to carry out

technical improvements without notice.

Lubrication

Service

WARNING

ENGLISH

Summary of Contents for 101072

Page 10: ...Notes 10 ENGLISH...

Page 15: ...Notas 10 ESPA OL...