Equipment does not

start.

The equipment starts,

but does not run at

high speed.

The equipment works,

but has low efficiency.

The equipment stops

when running.

No liquid comes out.

Spray volume and

pressure is not

enough.

The pressure is

adequate but the

spray is not.

The spraying mist is

uneven.

• Did not press the choke.

• Water mixed with fuel.

• Deterioration or carbon deposits on the spark

plug.

• No contact between spark plug and coil wire.

• Choke not in fully open position.

• Incorrect fuel ratio.

• Water in fuel.

• The air cleaner or filter is dirty.

• The outside of the cylinder and muffler have

carbon deposits.

• Piston, piston ring, cylinder is excessively

worn.

• Out of fuel.

• The coil or spark plug wire is loose.

• The spark plug is covered with carbon.

• The filter is clogged.

• Gasoline has water in it.

• The air hole in the tank cap is clogged.

• Inlet and outlet valves are blocked.

• Damaged washer.

• Damage to bearing 6004Z.

• Damage to the piston.

• The regulated pressure is not enough.

• The elastic force of the regulating spring is

not enough.

• Corrosion-resistant steel ball worn.

• Pressure regulating valve seat worn.

• Worn piston.

• Piston clearance not adequate.

• Inlet and outlet valves are worn.

• Spraying parts are clogged.

• The holes in the spraying nozzle are worn

out.

• The spraying parts are clogged.

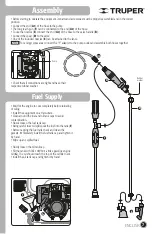

• Press 10 times as indicated. (p. 8)

• Change the fuel.

• Replace the spark plug.

• Check and adjust.

• Open to full position.

• Change fuel.

• Change fuel.

• Check and clean.

• Check and clean.

• Go to a Authorized

Service Center to replace.

• Add fuel.

• Check, replace and tighten.

• Replace spark plug.

• Clean filter.

• Change fuel.

• Clean it.

• Replace o clean.

• Go to a Authorized

Service Center to replace.

• Make the adjustment.

• Go to a Authorized

Service Center to replace.

• Go to a Authorized

Service Center or repairs or replacement.

• Clean the parts.

• Go to a Authorized

Service Center to replace.

• Clean the parts.

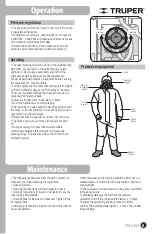

Problem

Cause

Solution

If the problems persist despite performing the recommended corrective actions,

contact a Authorized Service Center.

Troubleshooting

10

ENGLISH