9

Troubleshooting

ENGLISH

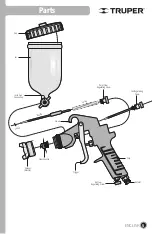

Wrong Spraying Pattern:

• Half Moon

• Leaning

• Divided

• Centered

• Paint build up in the nozzle.

• Paint build up in the nozzle or sprayer.

• Damaged nozzle.

• Nozzle wrongly tightened.

• Paint viscosity is too poor.

• Fluid outlet is too high.

• Paint viscosity is too high.

• Fluid outlet is too low.

• Remove the obstructions from the nozzle.

Do not use metal objects

to clean the funnel orifices.

• Remove the obstructions from the nozzle

and sprayer.

• Replace nozzle.

• Tighten the nozzle.

• Add paint to the mix.

• Adjust the paint flow regulator or the air

flow.

• Add thinner to the mix.

• Adjust the paint flow regulator or the air

flow.

Problem

Cause

Solution

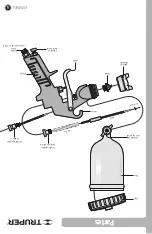

Wrong Fan:

• Fluctuation

• Divided

Air leaks.

Paint leaks.

Paint is not flowing.

• Air enters between the nozzle and

the gun body.

• Air is suctioned through the needle

seal gasket.

• Nozzle and needle are not

correctly set.

• Damaged nozzle and/or needle.

• Paint build up inside the gun

system.

• Residues or damage in the air flow

regulating screw. Components are

not correctly tightened.

• Residues or damage in the nozzle

and / or needle. Components are not

correctly tightened.

• Regulating paint flow screw is not

open enough.

• There is obstruction in the system.

• Clean the nozzle and the gun joint. If

damaged, replace the nozzle.

• Tighten the needle seal as indicated in page 8.

• Clean the nozzle and needle.

• Replace the fluids nozzle and the fluids

needle.

• Disassemble the gun parts and clean all the

components.

• Disassemble the system to check, clean and

tighten the air valve, its seat and washers.

Replace any damaged part.

• Disassemble the system to check, clean and

tighten the nozzle, needle its seat and washers.

Replace any damaged part.

• Turn the screw in a counterclockwise direction

to increase the flow.

• Disassemble the gun parts and clean all its

components.

Problem

Cause

Solution

Right Mist Pattern

Right Fan

CAUTION

Summary of Contents for 101855

Page 10: ...Notes 10 ENGLISH...