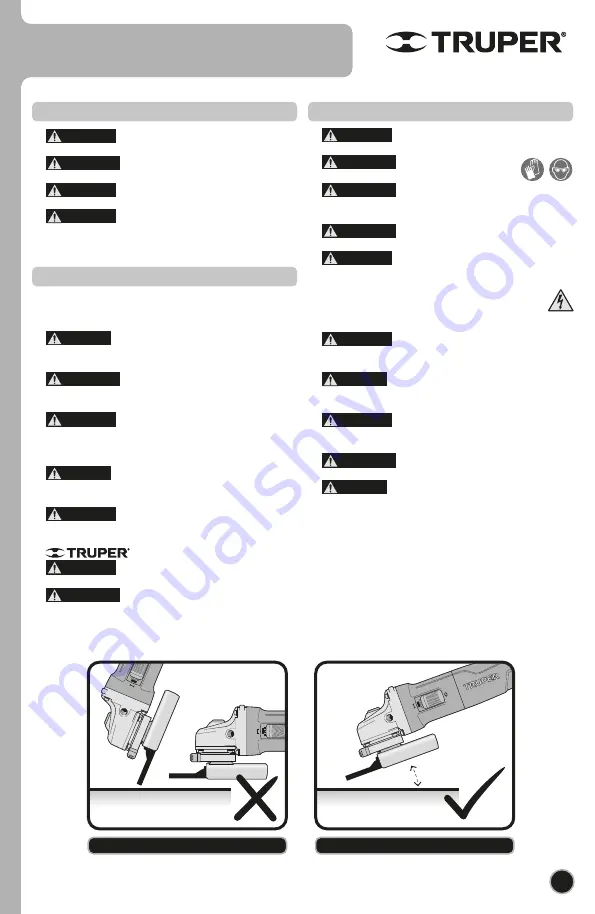

5

15° to 30°

ENGLISH

• Never use discs with bigger diameter

than the size required in the tool.

• Use only discs or accessories for

minimum or more than 11000 RPM speeds.

• Use only discs or accessories with an

orifice that fits perfectly in the tool spindle.

• Use only discs or accessories specifically

designed for the chosen material.

• Set apart some time and assess the job you are about to

do. Pay attention to all the necessary cautions before

starting to grind.

• Remove all the fastening wrenches from

the tool. Otherwise they can shoot away causing sever

injuries to the user.

• Double-check the guard. It should be

perfectly fastened and in good working condition. Do not

use the tool without a guard.

• Double-check the disc. It should not be

broken or cracked. Tap the disc gently with a wooden

hammer and listen for a strange sound to learn if is

cracked.

• Before plugging the tool, see if is in the

OFF position. Otherwise the tool could start unexpectedly

causing severe injuries.

• Run the tool 30 seconds before using,

to detect important vibration or any type of unusual

movement. If detected, unplug the tool and take it to a

Authorized Service Center.

• See if the disc rotates freely.

• Do not tighten the disc. It could brake.

• To work with small work pieces fasten

with wrenches. Never use your hands to hold the piece.

• Do not start the tool when the disc is

touching the work piece.

• Wear safety glasses, gloves

and an apron when using the tool.

• Keep the power cable or extension in

the back of the tool. Avoid accidentally damaging the

cables with the disc.

• Never hold the tool by the power

cable. Hold by the housing or auxiliary handle.

• Hold the tool by the isolated parts.

The cutting tool could come into contact with hidden

wiring or its own cable. Making contact with a “live” wire

causes the metal parts to electrify and give an electric

shock to the user.

• Never hit the work surface with the disc.

• To get the best result with the grinding

process, the inclination of the disc and the working

surface should have an angle measuring 15° to 30°

• When the disc is rotating never use the

spindle lock to stop it. It is very dangerous and may cause

injuries to the user.

• Do not touch the disc or the working

piece after grinding. Wait for them to cool down. Never

try to cool them down using water or oil.

• Before checking, adjusting or

changing discs, double-check the tool is not plugged in.

• Sparks caused when grinding may be

dangerous. Use caution. Make sure sparks do not get into

contact with skin or flammable substances.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

DANGER

DANGER

DANGER

Select the right disc

Before operating the grinder

While operating the grinder

Safety warnings for

angle grinders

Right way to operate the grinder

Wrong way to operate the grinder