8

Maintenance

ENGLISH

Cleansing and Care

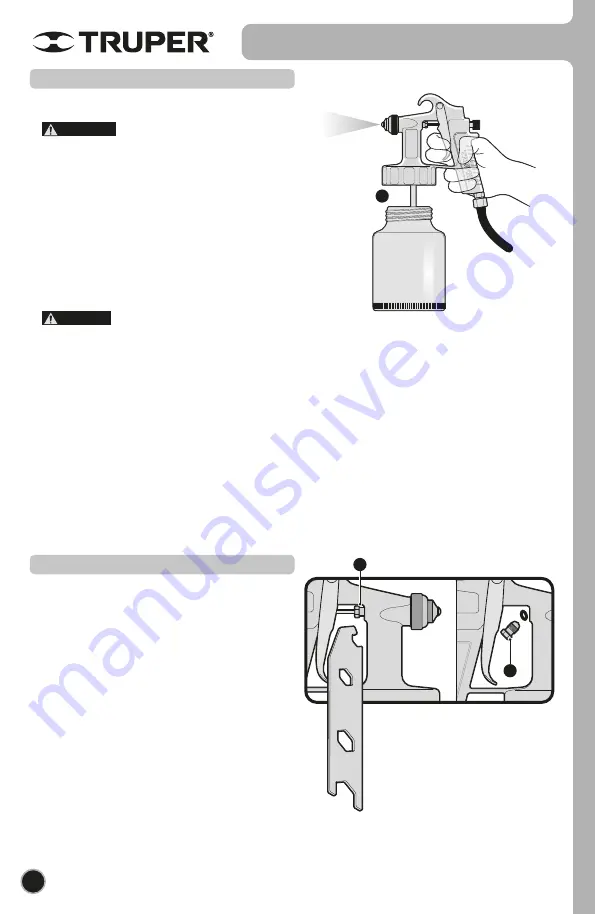

• Use special care adjusting the needle seal. This is very

important to obtain good results.

• Adjust the needle seal using a wrench (

B

).

• Periodically check the seal to be sure it is not damaged.

To gain access to the seal remove the needle and remove

the seal pressing piece (

C

).

Needle Seal

B

C

• It is very important to clean the spray gun thoroughly

after each use.

An inadequate cleansing can result in

malfunctioning and will cancel the Warranty.

• Turn the jar to remove it from the gun. Do not remove

completely. Press the trigger to remove remaining product

from inside the spray gun system (

A

).

• Pour the remaining material into an adequate container.

• Disconnect the paint gun hose.

• Clean the jar, the gasket seal and the suction pipe

thoroughly with a rag soaked with the solvent that is right

for the product.

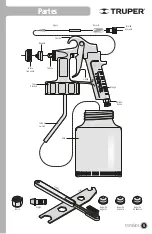

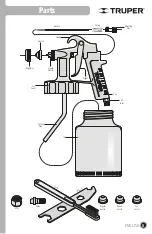

• Disassemble the regulator, the sprayer, the nozzle and

the needle. Clean them with a brush and solvent.

• Clean the paint gun body with a piece of rag moistened

with solvent.

Do not immerse the gun in solvent. The

gasket may get damaged.

• When the parts are clean assemble back the spray gun.

• Pour a small amount of solvent into the jar.

• Connect the hose to the spray gun.

• Start the compressor and spray into a container until

getting clean solvent out through the nozzle.

WARNING

CAUTION

A

Summary of Contents for 14037

Page 10: ...Notas 10 ESPA OL...

Page 20: ...Notes 10 ENGLISH PIPI 200...