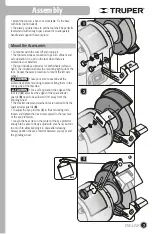

• Never try to use wheels with diameters

bigger than the size appropriate for the tool.

• Never use wheels that are damaged

or in bad repair. Otherwise they could break and get

thrown out towards the operator.

• Use wheels or accessories only for

3 500 RPM speeds or higher.

• Use only wheels or accessories with an

orifice matching the tool axis.

• Use only wheels or accessories specific

for the material to be used.

5

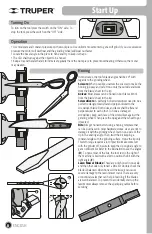

Choose the Right Griding Wheel

• Spare some time to assess the work to be made. Double

check you take all the necessary cautions before starting to

grind.

• Plan ahead the way to hold the work piece. Avoid

positions which could make you lose control over your

hands. If there is a sudden slip the hand could make

contact with the moving disc.

• Remove all the wrenches from the tool.

Otherwise the wrenches may be shot with great force

causing severe injuries to the operator.

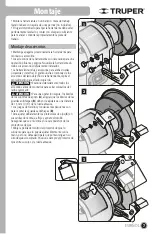

• Double check that the protections are

in good repair and correctly fastened. The tool shall not be

used without protections.

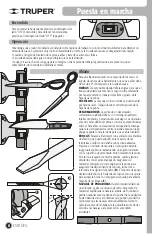

• Verify the wheel is not broken or

cracked. Hit lightly the disc with a wood hammer. The

sound will tell you if it’s cracked. Replace immediately a

broken disc before operating the tool.

• Turn on the tool 30 seconds before

using to detect considerable vibrations or any type of

unusual movement. If detected, disconnect the tool and go

to a

Authorized Service Center.

• Verify the wheel runs freely. Do not

tighten the disc too much. Otherwise it could break.

• Top work with small work pieces fix

them with clamps or vices. Never use your hands to hold

pieces.

Before Operating the Bench Grinder

• Keep your fingers in a safe distance away from the

grinding disc.

• Do not start the tool when the wheel

is making contact with the work piece.

• Wear safety eyeglasses, gloves

and apron when operating the tool.

• Keep the cable or extension cable

behind the tool to prevent accidentally damage the cable

with the disc.

• Do not touch the wheel or the work

piece immediately after grinding. Manipulate them only

when cooled down. Do not try to cool down the wheel or

piece using water or oil.

• Verify the tool is disconnected before

checking, adjusting or replacing the disc.

• Sparks coming out from grinding can

be dangerous if adequate measures are not taken.

Double check sparks do not come into contact with skin

or flammable substances.

• Do not stretch over the machine to

overreach. Use a safe posture and always keep good

footing.

• The feed direction of the work piece shall be directed

against the disc rotation.

• Prevent damages due to jamming, sliding or movement

of the work piece. Make sure all the vices and locks are

tight and that no part has excessive movement.

• If a small piece gets stuck inside the guard turn off the

machine immediately, disconnect from the power outlet

and wait until all the mobile parts stop completely before

trying to remove the stuck piece.

While Operating the Bench Grinder

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

DANGER

DANGER

ENGLISH

Safety Warnings for the

Use of Bench Grinders