9

ENGLISH

Carbon brush replacement

• Always disconnect the tool before cleaning.

• Never use water or other liquids. Use only a brush.

• To prevent the motor to overheat clean the ventilation slots regularly.

• Check all the tool components are perfectly fixed.

• The housing should not be cracked or damaged.

• Double-check the power cable is not cut or peeled.

• After a prolonged use the grease on the tool head should be replaced in a

Authorized Service Center.

Use only spare parts and accessories recommended by the manufacturer. In

the event the tool is not working, repairs should be performed in a

Authorized Service Center

Repairs

Neatly store the tool in a dry place and protected from dust and water .

Storage

• Replace worn (burnt, broken or smaller than 0.19” long) carbon brushes. Use

new carbons.

• When changing carbons always change both carbons at the same time.

• Remove worn carbons from the housing. Clean dust with compressed air.

• Set the new carbons in a reverse order. Carbon should easily fall into the

carbon housing.

• After setting up new carbon brushes let the grinder to run a couple of

minutes with no load. This way the carbon brushes will adjust better.

• Use only original spare carbon brushes, designed

specifically with the right strength and electric resistance for each type of motor.

Carbon brushes with different specifications may damage the motor.

• For better results, it is recommended to use grinding and/or cutting disc to

4-1/2"

Maintenance

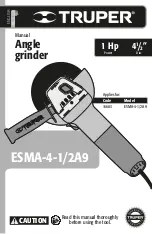

Summary of Contents for ESMA-4-1/2A9

Page 10: ...10 ENGLISH Notes...

Page 15: ...10 Notas ESPA OL...