8

Use only spare parts and accessories recommended by the manufacturer. In

the event the tool is not working, repairs should be carried out in a

Authorized Service Center.

Start Up

Maintenance

Repairs

Useful Tips

• Before cleaning the tool disconnect the tool.

• Never use water or other liquids. Use only a brush.

• To avoid motor overheating clean the ventilation slots regularly.

• Double-check all the tool components are securely fastened.

• The housing should not be cracked or damaged.

• Double-check the power cable is not cut or peeled.

• After a prolonged use the grease on the tool head should be replaced in a

Authorized Service Center.

Store the tool neatly in a dry place. Protect against dust and water.

Storage

• Replace worn (burnt, broken or smaller than 0.19” long) carbon brushes. Use

new carbons.

• When replacing carbons always replace both carbons at the same time.

• Remove worn carbons from the housing. Clean accumulated dust with

compressed air.

• Set the new carbons in a reverse order. Carbons should easily fall into the

carbon housing.

• After setting up new carbon brushes let the grinder running a couple of

minutes unloaded. This way the carbon brushes will adjust better.

• Use only original spare carbon brushes, designed

specifically with the right strength and electric resistance for each type of motor.

Carbon brushes with different specifications may damage the motor.

Carbon Brush Replacement

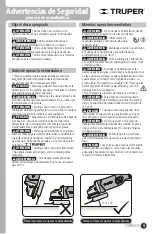

• To prevent damaging the disc work using the disc into the right position.

• Press onto the work piece using less force than the tool’s weight to avoid overload and

damaging the motor and disc.

• After installing a new disc allow it to rotate with no load at least during one minute. If it vibrates,

replace immediately.

• Avoid working onto wood or soft materials like lead. These materials saturate

the disc very fast and make it unusable.

ENGLISH

CAUTION