Page 15

SERVICE & MAINTENANCE - PETROL & DIESEL

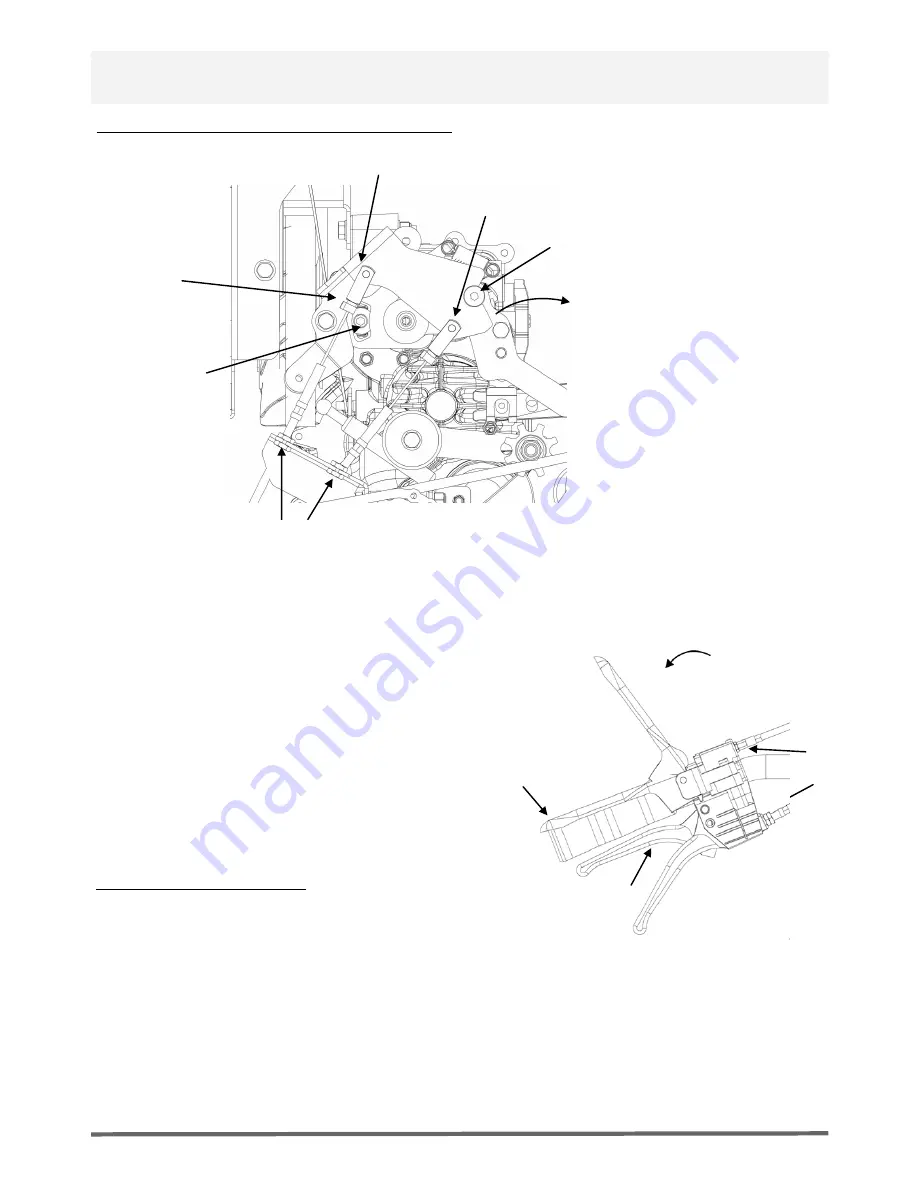

PUMP CONTROL SETTINGS & ADJUSTMENT

FORWARD CONTROL CABLE

REARWARD CONTROL CABLE

DIRECTION SAFETY PIN

(SHOWN IN LOCKED POSITION)

CABLE ADJUSTMENT NUTS

PUMP NEU-

TRAL SETTING

SCREW

DEPRESS DEADMAN LEVER

TO DISENGAGE PIN

PUMP DIREC-

TION BRACKET

1: Adjust Deadman lever cable tension if required, see engage angle. Adjust cable adjustment nuts. With Deadman

lever in fully pressed position ensure the direction safety pin is clear of control plate (see above)

2: Adjust forward/reverse direction levers cable tension if

required, ensure 3mm - 5mm gap when fully pressed.

Adjust cable adjustment nuts.

3: Ensure that with forward lever fully pressed the pump

direction bracket turns

15 degree forward direction 75 rpm @ wheels

4: Ensure that with rearward lever fully pressed the pump

direction bracket turns

5 degree rearward direction 30 rpm @ wheels

PUMP NEUTRAL SETTING

1: Adjust pump neutral setting if required if machine creeps

forwards/backwards when in neutral,

disconnect forward and rearward control cables

fully press Deadman lever to disengage the direction safety

pin

loosen pump neutral setting screw

adjust angle of pump control bracket by rotating forward/

backward until no creep

re tighten pump neutral setting screw when wheel rotation is

0 rpm

CABLE

ADJUSTMENT

NUTS

DEADMAN LEVER

ENGAGE ANGLE

10-

20 degree

DEADMAN LEVER

FULLY PRESSED

POSITION

DIRECTION LEVERS

GAP TO HANDLE 5MM

WHEN FULLY

PRESSED

Summary of Contents for BENDI 300D

Page 8: ......

Page 17: ...ELECTRIC TRUXTA WARNING SYMBOLS DECALS Page 17...

Page 18: ...Page 18 ELECTRIC TRUXTA WIRING DIAGRAM DIAGNOSTICS TROUBLESHOOTING...

Page 20: ...DIAGNOSTICS TROUBLESHOOTING TRUXTA ELECTRIC Page 20...

Page 21: ...ELECTRIC TRUXTA DIAGNOSTICS TROUBLESHOOTING Page 21...

Page 23: ...TOP FRAME STEERING ASSEMBLY Page 23 800 18003 0 25 04 16...

Page 25: ...Page 25 FRONT CHASSIS ASSEMBLY 800 18002 0 19 04 16...

Page 27: ...Page 27 REAR ASSEMBLY ALL ENGINE MODELS 800 18000 0 19 04 16...

Page 29: ...Page 29 ELECTRIC REAR ASSEMBLY 800 18001 0 19 04 16...