10

© TrynEx International 2013 (REV A) F51073A

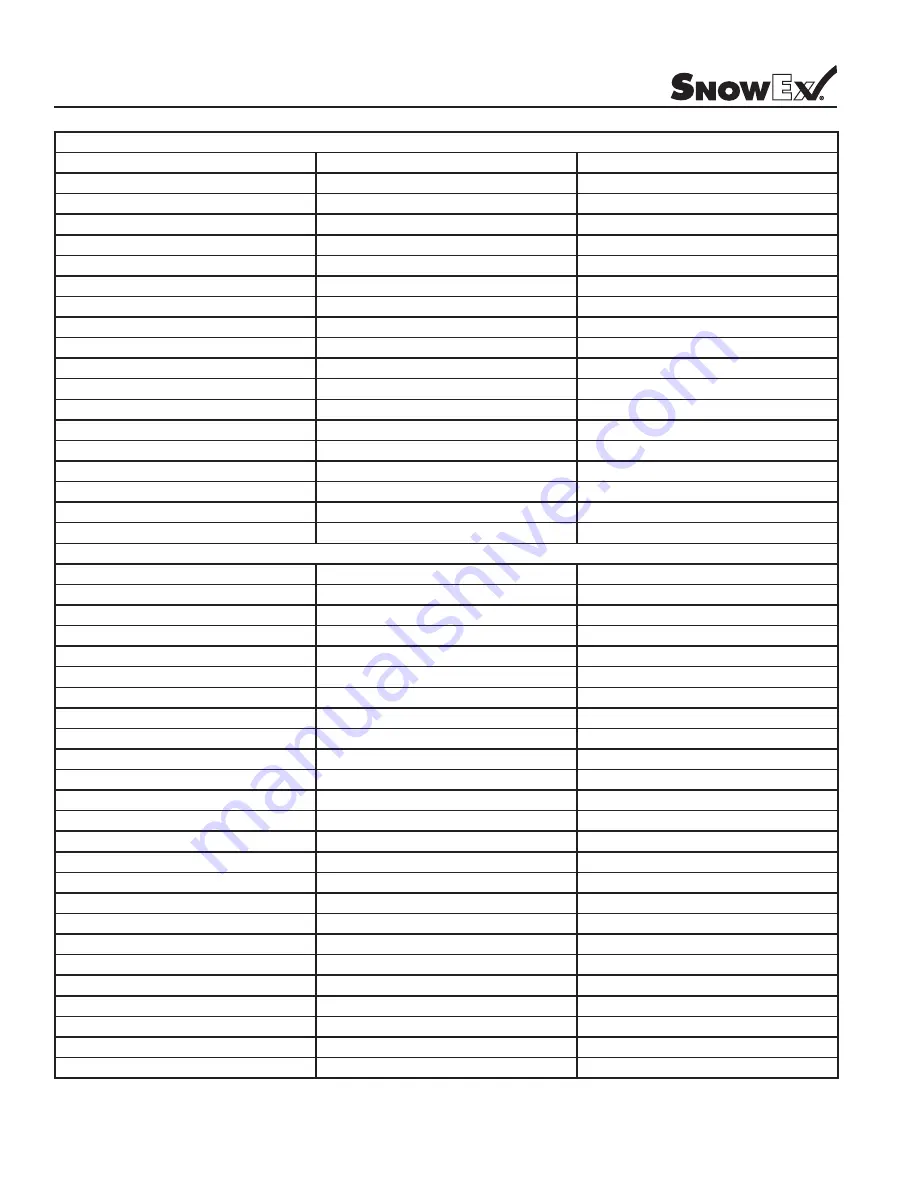

Troubleshooting

Material Flow

Fault

Possible Cause

Remedy

Too much material

Auger Speed too high

Decrease Auger Speed

Increase Spinner Speed

Vibrator is on

Turn Vibrator off. Use intermittently.

Adjustable Baffles open too much

Adjust Baffles

Material is very fine

Use a more-coarse material

Adjust Baffles

Not enough material

Auger Speed too low

Increase Auger Speed

Decrease Spinner Speed

Material is bridged in hopper

Use Vibrator

Material Baffles closed too much

Adjust Baffles

No Material is Spreading

Control is off

Turn control on

Material is bridged

Use Vibrator

Foreign object in Hopper

Remove Object

Hopper is Empty

Fill Hopper

No Power to Auger Motor

Reset Circuit Breaker

Put Dielectric Grease on all Connections

Check Harnesses for damage

Contact your dealer

Controller

Fault

Possible Cause

Remedy

OL

Jammed Material

Engage Auto-Reverse

Auger Over-Full

Turn off vibrator (if on)

Engage Auto-Reverse

Adjust Baffles to restrict flow

Foreign Object in Hopper

Remove Object

Frozen Material

Shovel it out

Material on Spinner at Start-Up

Use shovel or snow brush to clear material off spinner

EO

Spreader Harness Unplugged

Re-Connect/Dielectric Grease

Spinner Drive Unplugged

Re-Connect/Dielectric Grease

Motor Unplugged

Re-Connect/Dielectric Grease

Cut in harness

check all harness, replace affected harness(es)

LB

Corroded Connection

Clean/Dielectric Grease

Replace Connectors

Loose Connection

Tighten/Dielectric Grease

Replace

Low Battery (less than 12 volts)

Charge Battery

Test Battery, Replace if bad

Test Alternator, Replace if bad

E1

Wires Crossed

Check Harnesses for bare wires

Check for loose wires/connections

On/Off Switch Lights, No Display

Controller not connected

Check all connections at the back of Controller

No Display, On/Off Switch does not light up

No Power to Controller

Reset Breaker

Check for Cuts in Battery Harness

Test Controller (Contact Dealer)

Summary of Contents for SnowEx Precision Pro SP-1675

Page 11: ...11 TrynEx International 2013 REV A F51073A Notes...

Page 12: ...133009...