6

DESIGN AND APPLICATION:

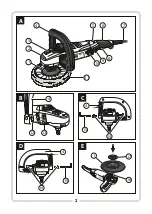

Fig.B 12.

Pin

The rotary buffer (hereinafter referred to as “buffer”) is a hand-held

power tool driven by a single-phase, commutator-type motor. It is

Fig.C 14.

Fixing screws with hex socket

equipped with an auxiliary handle that can be set in two positions.

15.

Allen (hex) key

Class II equipment (double insulation).

Fig.E 16.

Spindle

17.

Clamping nut

The buffer is designed for polishing metal surfaces, plastic products and

painted surfaces, including vehicles.

18.

Locking wrench

This electric tool is designed for jobs with medium intensity. It is not

TECHNICAL DATA:

suitable for long-term operation under heavy duty conditions.

Do never

use the tool for applications that need use of professional

equipment.

BEFORE YOU START:

1. Make sure that electric parameters of the power voltage correspond

to parameters of the electric tool according to specifications on the

rating plate.

2. Make sure that the On/Off switch (

8

) of the electric tool is in its Off

THE SET CONTAINS:

position.

ź

Buffer - 1piece

3. While working with a power cord extension make sure that electric

ź

Auxiliary handle -1piece

parameters of the extension cable and cross-sections of its wires are

ź

Fixing screws with hexagonal socket - 2 pieces

appropriated for corresponding parameters of the electric tool. The

ź

Buffing disk - 1piece

extension cable must be fully uncoiled.

ź

Clamping nut -1piece

n

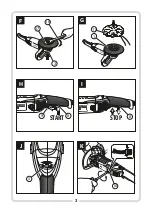

Installing the auxiliary handle

ź

Locking wrench -1piece

ź

Allen (hex) key -1piece

ź

Buffing pad -1piece

Transport

ation

case

-1 piece

NOTE:

For safety reasons always use its auxiliary handle during operation.

Warranty card -1 piece

Set the auxiliary handle (

4

) to align its pin (

12

) with groove (

13

) in the

-1 piece

power tool head body (fig.

B

).

Set fixing screws with hex socket (

14

) and turn them using the Allen key

DRAWING DESCRIPTION

(see pages 2-3)

:

(

15

). The auxiliary handle (

4

) can be installed in two ways as shown in

Fig.A

1.

Buffing disk

Fig.

C

and

D

, thus selecting the most comfortable setting.

2.

Arrow that indicates rotation direction

n

Installing and removing the buffing disk

3.

Spindle lock button

ź

Put the buffer with spindle (

16

) upwards. Place the buffing disk (

1

)

4.

Auxiliary handle

with its bottom protruding part onto the spindle pin to engage the

5.

Speed adjustment knob

disk on the spindle.

6.

Main handle

ź

Screw the clamping nut (

17

) onto the spindle to fix the disk securely

7.

Power cord

(fig.

E

).

8.

Switch

ź

Press the spindle lock button (

3

)

and tighten the locking nut exerting

9.

Locking lever

slight pressure using the locking wrench (

18

) provided, as during

10.

Brush-holder

operation the nut tightens up automatically. Following the above-

11.

Buffing pad

mentioned tip will result in avoiding damage to the reducer casing

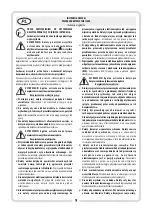

Each application of the tool not in line with the intended use as specified

below is strictly forbidden and makes the warranty terms null and void.

The manufacturer shall not be held responsible for possible

consequential damage that may arise due to or in connection with such

application.

Any modifications of the tool by the user relieve the manufacturer from

responsibility for any damage and injuries to the user and the

surroundings.

Proper use cannot guarantee that no residual risk will occur. Due to the

design of the machine, the following risks may occur:

-

catching and entangling clothes by moving parts;

-

hearing impairment in case of long-term operation without ear

protectors;

-

eye injury resulted from throwing off buffed material particles;

- t

hrowing a machined part or pieces of a machined part

;

- emission dust hazardous for human health when works are carried out

in closed rooms (confined areas).

WARNING! Prior to installation and adjustment

always disconnect the plug from the mains socket.

ź

ź

ź

O

perating instruction

13.

Groove

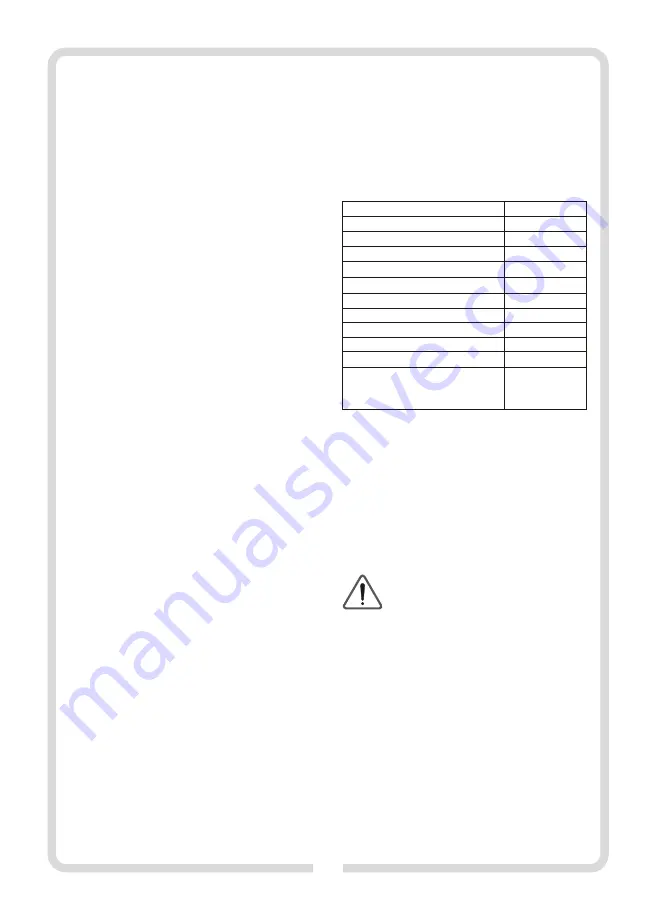

Rated voltage

230-240

V

Rated frequency

50

Hz

Power consumption

130

0

W

Max

. s

peed

under no-load conditions

rpm

33

00

Max. disk diameter

180

mm

Spindle thread

M14

Equipment class

II

Power cord length

5

m

Weight

3,6

к

g

Sound pressure level (LpA)

K=3

dB(A)

dB(A)

93

Sound power level (LwA)

K=3

dB(A)

dB(A)

104

Vibration level according to EN 60745-1:2009

2

(measuring tolerance

K=

1

,

5m/s

)

polishing the surface

a

h AG

6

,

972

2

m/s

Summary of Contents for TMA1300K

Page 2: ...2 A 1300W 1 2 3 4 5 7 8 9 10 11 B 12 13 C D 14 14 15 4 15 4 E 17 1 16 13 00 W 6 4...

Page 14: ...RCD TMA1300K 14...

Page 15: ...15 a a...

Page 16: ...16...

Page 19: ...19 n 10 5 7 n K 6 34 03 228 PROFIX...

Page 36: ......