8

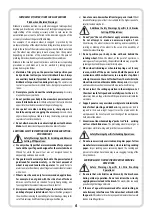

One must implement additional safety measures to protect the operators

from exposure to vibrations, such as maintenance of the electric tool and

work tools, assurance of proper hand temperature, or determination of

the sequence of work operations.

NOTE:

Due to safety reasons the On/Off

(

8

) cannot be locked for

continuous operation. It must be kept depressed manually by the operator

during the entire time of the tool operation.

n

Grinding angle

Do not use the whole disk surface to grind, use its edge only.

For efficient grinding the angle between the disk and machined part

º

º

should range from approx. 15 to 30 (see: Fig.

I

, p.

3

).

n

Rough grinding

For best rough grinding efficiency the angle between the disk and

º

º

machined surface should range from approx. 30 do 40 (see: Fig.

J

, p.

3

).

The tool should be slightly pressed against the surface and smoothly

moved along the material. Thanks to the right pressure the machined

part does not heat up excessively, does not lose its color and no grooves

or other roughness will appear on its surface.

NOTE:

Never use cutting disks to grind/remove layers.

n

Cutting

While cutting with the tool do not exert excessive pressure, do not tilt

and do not oscillate. Move the tool at a constant speed adjusted to the

material machined.

Do not brake the rotating disk by pressing it against other objects.

NOTE:

Observe proper cutting direction. Cutting should be carried out at

the direction shown on the disk (see: Fig.

K

, p.

3

). Do not cut in opposite

direction! Otherwise the tool may be pulled out from the cutting line.

n

Trial start up

After inserting a disk and after connecting the grinder to the mains check

whether the disk is properly fixed and whether it rotates without any

obstacles.

The initial/trial start up should be carried our away from people.

BEFORE YOU START WORKING:

1. Make sure that the power source parameters match the parameters

presented on the grinder nameplate.

2. Make sure that the grinder power switch (

8

) is in off position.

3. When using an extension cable make sure the extension cable

REGULAR OPERATION:

parameters and conductor sections match the grinder parameters. It

n

Switching on/off

is recommended to use the shortest extension cables possible. The

Before you switch on the tool check if the switch (

8

) is in working order

extension cable should be fully unwound.

and returns to “Off” position after releasing.

To protect the grinder against accidental start, the switch (

8

) is equipped

n

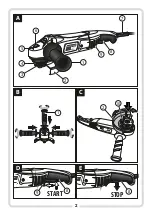

Mounting the side handle

with a locking lever (

9

).

NOTE:

For safety reasons always use the side handle (

1

).

To start the grinder:

Depending on the operating requirements screw the side handle to the

1. P

ress the locking lever (

9

) towards the arrow (see: Fig.

D

, p.

2

),

end in one of th

re

e seats provided in the grinder head (see: Fig.

B

, p.

2

).

2. P

ress the switch button (

8

).

n

Mounting the disk guard

To stop the tool just release the switch

(

8

)

(see: Fig.

E

, p.

2

).

NOTE:

Before you install or remove the disk guard, make sure that the

switch

device switch is in off position and that it is disconnected from the mains.

To cut or grind with grinding or cutting disks it is necessary to install the

disk guard (

2

). Adjust the guard position to the operation performed.

n

Tips regarding the operation

The closed side of the guard should be always directed towards the

ź

The objects to be machined that do not rest securely under their own

operator. To install the disk guard:

weight should be fixed properly.

1.

Place the grinder with the spindle (

11

) up.

ź

Avoid excessive pressure exerted on the disk. Grinding should be

2.

Install the blade guard as shown in Figure

C

, page

2

.

carried out using the weight of the tool. Only slight pressure is allowed

3.

Match holes on the guard flange (

10

) with mounting holes in

when cutting. Excessive pressure reduces the disk speed, which results

grinder's head and insert fixing screws into the flange. Tighten

in producing rough surfaces. In addition, it results in overheating and

securely the screws using a Phillips type screwdriver (Ph2).

damage to the motor.

n

Grinding tools assembly

(see: Fig.

F

,

G

,

H

p.

3

)

n

Grinding direction

NOTE:

Before you install or remove the grinding disk, make sure that the

When using a new grinding disk move the grinder back (

B

direction)

device switch is in off position and that it is disconnected from the mains.

(see: Fig.

I

, p.

3

), then the new disk edge will be rounded, which will allow

Before installation clean the grinder spindle and all fixing components.

the user to move the tool in any direction.

Make sure the admissible size and speed of the grinding disk matches

the parameters presented on the grinder nameplate. The grinding disk

should be installed without any clearance on the fixing flange. Do not

use any reduction washers or adapters.

To install a disk:

1.

Place the grinder with the spindle (

11

) up. Insert the fixing flange (

4

)

with its bottom projecting part with a groove onto the spindle shaft

to mesh the flange on the spindle.

2. Insert a disk (

12

) with its convex part down onto the upper projecting

part of the fixing flange.

3. Screw the compression nut (

3

) onto the spindle to secure the disk

properly. The compression nut has a concave and convex side.

Depending on the rated disk thickness it can be applied on one or the

other side

(see: Fig.

G

p.

3

).

4. Press the spindle lock button (

6

) and tighten the nut using the pin

wrench (

13

) exerting a slight force as the nut automatically tightens

up during operation. Observing this recommendation will help

avoiding damage to the motoreducer casing during the disk removal.

NOTE:

The spindle lock button (

6

) can be pressed only when the spindle is

stopped!

Never use a disk with improper maximum admissible speed!

3 minutes or more

1 minute or more

Trial operation

period

After disk replacement

At first start up

Summary of Contents for TMS12519

Page 2: ...2 10 C 10 10 W 2 A 1010W 7 1 2 3 4 6 8 9 B 1 STOP E 8 D START 1 2 8 9 5...

Page 17: ...17 RCD TMS12519...

Page 18: ...18 a a...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21 a...

Page 24: ...24 n K 3 n 7 34 03 228 PROFIX...

Page 60: ......