56

Bline Mode

Scan Mark

Intensity x

Ref. Level xxx

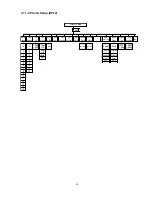

3. Open the print head mechanism, put

the black mark under the media

sensor. Press the

button

to set the value into the printer.

Bline Mode

Scan Paper

Intensity x

Ref. Level xxx

4. Then, put the label without black mark

under the media sensor. Press the

button to set the value into

the printer.

Note:

Normally, the value of

“Ref. Level” for mark should be larger than paper

for over 128. If the media sensor fails to do so, you have to manually

change the Intensity by pressing

and

to reach the

above value.

Bline Mode

Complete

Intensity x

Ref. Level xxx

5. The bline sensor calibration is

complete. Press the

button the LCD screen will return to

the previous menu.

B-3 Pre-Printed

This function can set the paper length and gap size before auto-calibrate the

sensor sensitivity. It can to get the sensor sensitivity accurately.

When enter [Pre-Printed] option, you will see following message. Please

Bline Mode 3/4

Manual

>

Pre-Printed

Exit

Media sensor

Black mark

Media sensor

Label without

black mark

Summary of Contents for 346M Pro

Page 23: ...18 Loading path for ribbon...

Page 30: ...25...